Strong-flavor camellia oil cold-pressing process

A camellia oil and strong-flavor technology, applied in the field of vegetable oil, can solve the problems of low oil yield, low quality, and many impurities in camellia oil, and achieve the effects of low production cost, high nutritional value and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

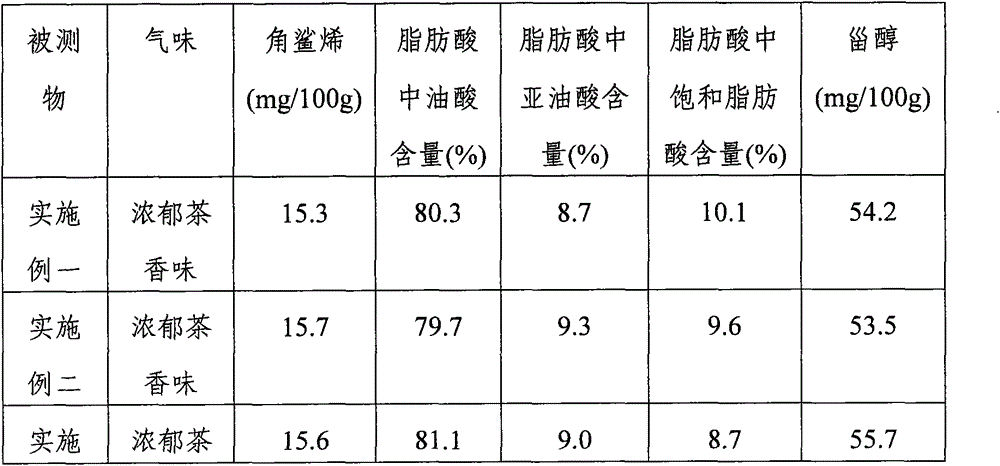

Examples

Embodiment 1

[0026] A cold-pressing process of Luzhou-flavor type camellia oil, comprising the following steps:

[0027] (1) Select the camellia seeds that fall naturally after the camellia fruit matures, and sort them with a sorting machine to remove mildewed camellia seeds and impurities;

[0028] (2) Place the camellia seeds treated in step (1) in an oven at a temperature of 40°C and dry until the moisture content is 5%, then take out the camellia seeds and spread them out for 40 minutes to make the moisture content 8% before bagging and sealed for later use;

[0029] (3) placing the camellia seeds treated in step (2) in a double-roll sheller for peeling, so that the weight ratio of the seed shells to the tea kernels is 8:100, and the camellia kernels are obtained;

[0030] (4) Put the camellia kernels obtained in step (3) into a steaming pan, steam and fry at a temperature of 60° C. for 20 minutes, and adjust the moisture content of the camellia kernels to 7%;

[0031] (5) Press the ...

Embodiment 2

[0035] A cold-pressing process of Luzhou-flavor type camellia oil, comprising the following steps:

[0036] (1) Select the camellia seeds that fall naturally after the camellia fruit matures, and sort them with a sorting machine to remove mildewed camellia seeds and impurities;

[0037] (2) Place the camellia seeds treated in step (1) in an oven with a temperature of 50°C and dry until the moisture content is 3%, then take out the camellia seeds and spread them out for 60 minutes to make the moisture content 6% before bagging and sealed for later use;

[0038] (3) placing the camellia seeds treated in step (2) in a double-roll sheller for peeling, so that the weight ratio of the seed shells to the tea kernels is 12:100, and the camellia kernels are obtained;

[0039] (4) Put the camellia kernels obtained in step (3) into a steaming wok, steam and fry at a temperature of 70° C. for 15 minutes, and adjust the moisture content of the camellia kernels to 6%;

[0040] (5) Press t...

Embodiment 3

[0044] A cold-pressing process of Luzhou-flavor type camellia oil, comprising the following steps:

[0045] (1) Select the camellia seeds that fall naturally after the camellia fruit matures, and sort them with a sorting machine to remove mildewed camellia seeds and impurities;

[0046] (2) Place the camellia seeds treated in step (1) in an oven with a temperature of 45°C and dry until the moisture content is 4%, then take out the camellia seeds and spread them in the air for 50 minutes, so that the moisture content is 7% and then bagged and sealed for later use;

[0047] (3) placing the camellia seeds treated in step (2) in a double-roller sheller for peeling, so that the weight ratio of the seed shells to the tea kernels is 10:100, and the camellia kernels are obtained;

[0048] (4) Put the camellia kernels obtained in step (3) into a steaming wok, steam and fry at a temperature of 65° C. for 18 minutes, and adjust the moisture content of the camellia kernels to 6%;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com