Finished tobacco shred automatic box type storage and transfer technology

An automatic conveying and automatic boxing technology is applied in the field of storage and conveying technology of finished cut tobacco, which can solve the problems of limited production scheduling flexibility, inconvenient tobacco production scheduling, and difficult temperature and humidity control, and achieves refined production scheduling management mode, Improve the level of automatic production management and reduce the effect of tobacco aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

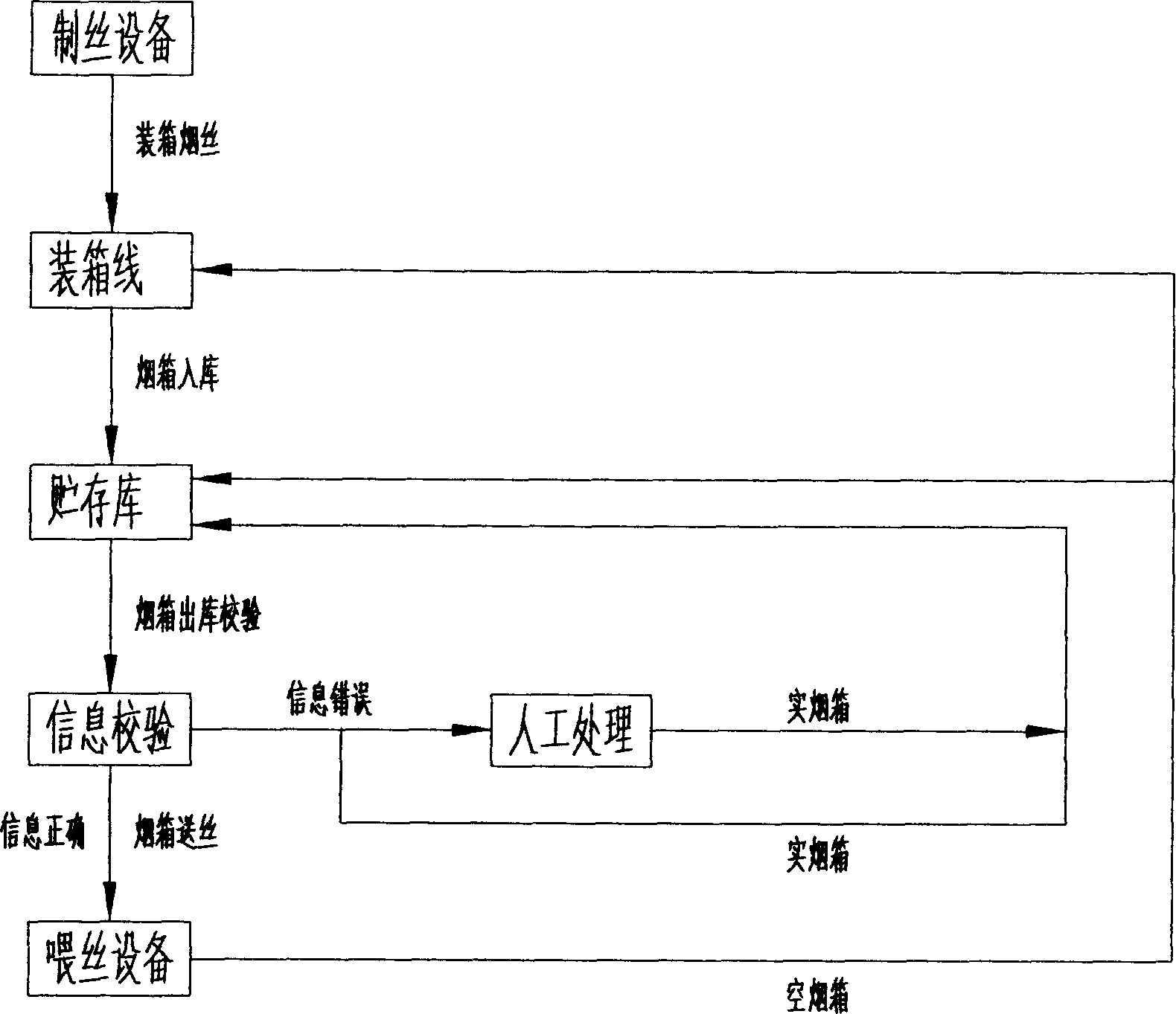

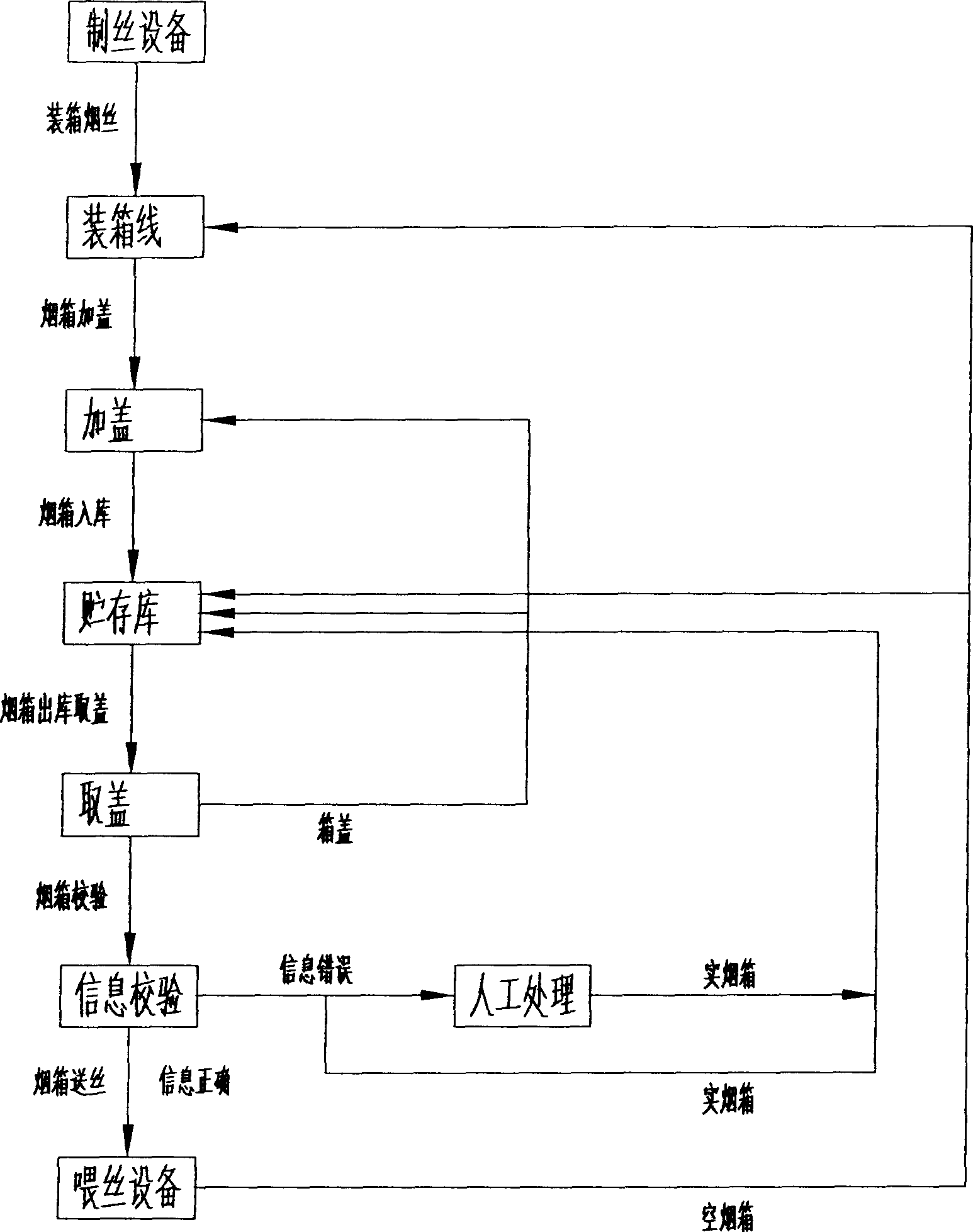

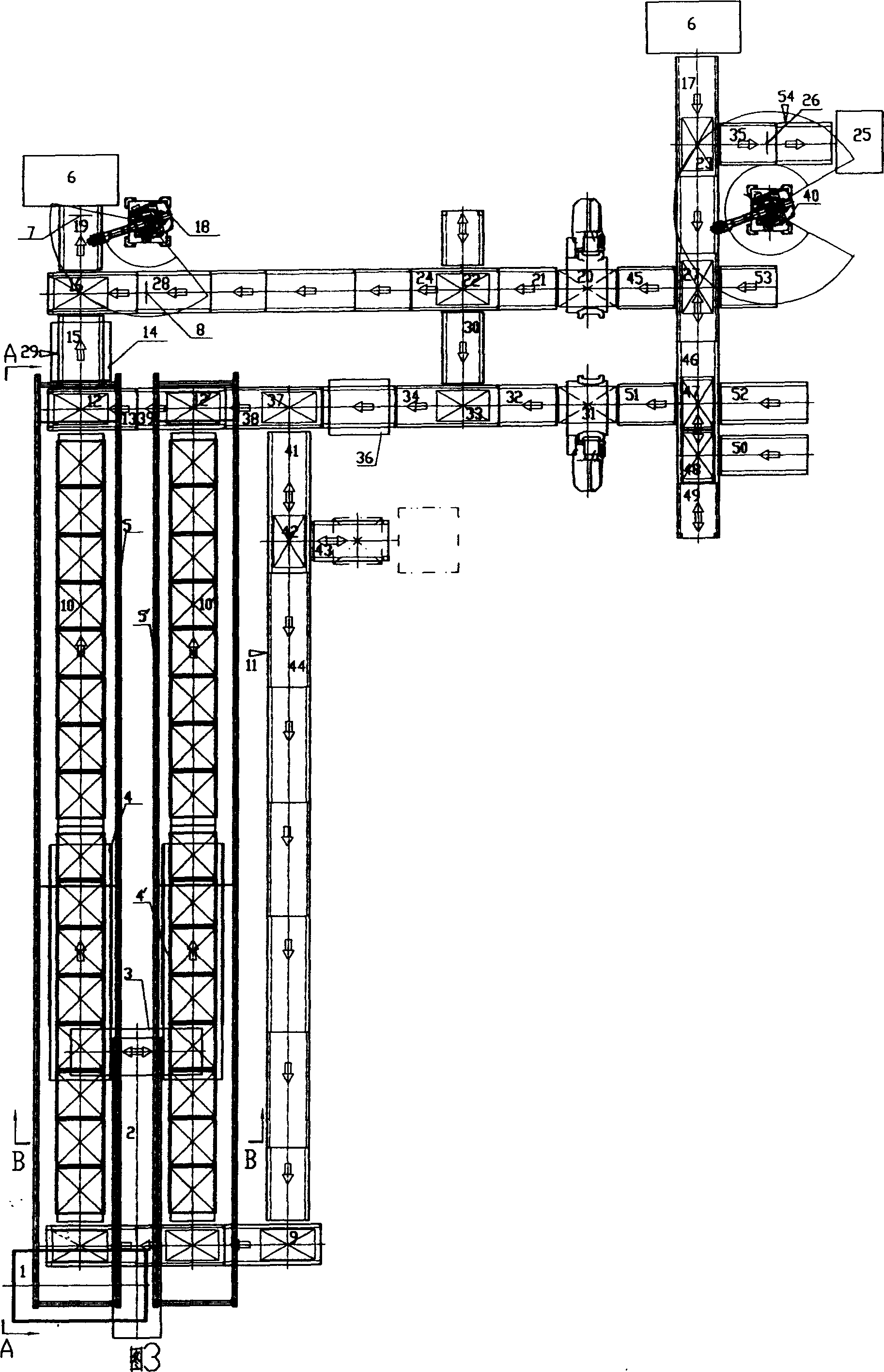

[0020] like figure 1 As shown, the process of the present invention is a process between the tobacco plant silk making equipment and the silk feeding equipment, and the process includes the following branching process:

[0021] ①. Automatic conveying of finished shredded tobacco→automatic boxing→automatic warehousing process, the process steps are:

[0022] a. Automatic conveying: through the automatic control system, the finished shredded tobacco from the shredded equipment is sent to the material distributing device on the packing line by the conveying device;

[0023] b. Automatic boxing: use the distributing device to pack the shredded tobacco into the empty cigarette box placed on the conveying device in advance;

[0024] c. Automatic warehousing: the conveying device automatically transports the solid tobacco boxes filled with shredded tobacco to the storage warehouse;

[0025] ②. Automatic delivery process: the solid smoke box in the storage is automatically transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com