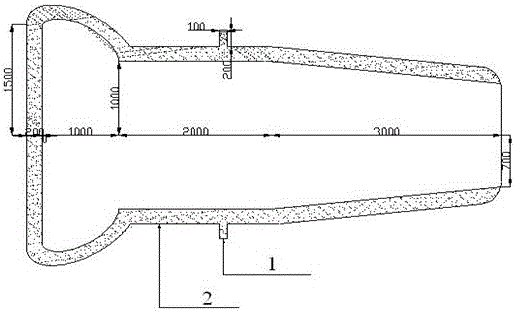

A rotary tube capable of converting a ball milled condensing tube into a straight condensing tube

A technology of straight condensing tubes and rotary tubes, which is applied in the field of experimental equipment conversion devices, can solve problems such as waste of economy, time and effort, and achieve the effects of avoiding transfer losses, improving extraction efficiency, and saving laboratory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] 1 Rotary evaporator decompression test

[0011] In order to verify the practicability of the utility model patent, this rotary tube was selected for decompression test comparison with Shanghai Zhenjie RE-52AA rotary evaporator.

[0012] The specific implementation process: 1. After the ball mill port condensing tube rotary evaporator and the straight port rotary evaporator are respectively connected, turn on the vacuum pump button to start vacuuming. You can see that the vacuum pump instrument panel shows that the vacuum degree of the condensing tube in the vacuum rotary evaporator rises rapidly, the highest It can reach 1000. 2. Contrast test of the rotary tube: connect the upper end of the rotary tube to the ball milling port of the condenser tube, fix it with stainless steel clips, insert the lower end into the collection bottle, and fix the collection bottle to the fixed protrusion with stainless steel clips. Turn on the vacuum pump, and it can be found that the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com