Nitrogen blowing instrument automatic control device and monitoring control method

An automatic control device and nitrogen blowing instrument technology, applied in the detection field, can solve the problems of measurement accuracy, temperature sensitivity, large volume, etc., and achieve the effects of avoiding errors and labor, ensuring accuracy and speed, and ensuring concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] An automatic control device for a nitrogen blowing instrument, including an information collection system, a fixed mobile mechanism, and a control system;

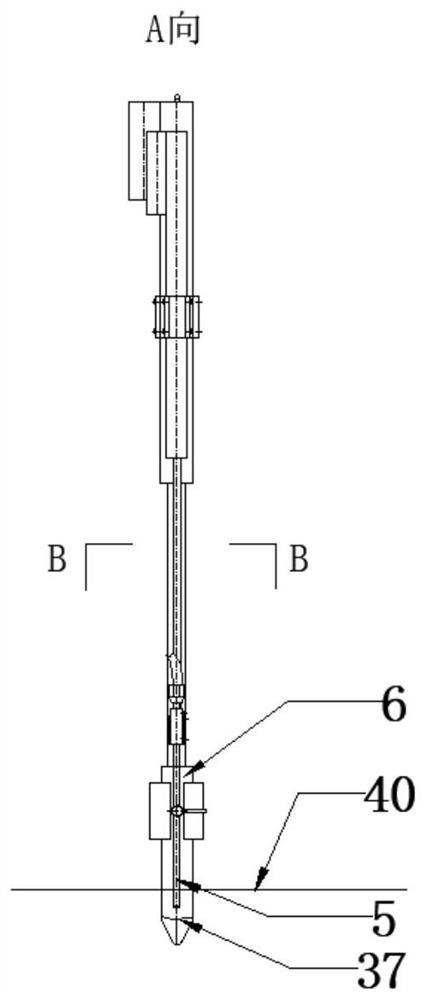

[0068] The information collection system includes a macro camera 1 installed on a fixed mobile mechanism and a liquid level sensor 2 in a water bath environment; the macro camera 1 is used to collect the liquid level of the sample in the transparent test tube 6;

[0069] The fixed moving mechanism includes a first lifting mechanism 3 and a second lifting mechanism 4;

[0070] The first lifting mechanism 3 is used to drive the nitrogen blowing pipe 5 to move up and down, and extend the nitrogen blowing pipe 5 into the transparent test tube 6 to blow nitrogen to the sample in the transparent test tube 6;

[0071] The second lifting mechanism 4 is used to drive the transparent test tube 6 to move up and down, so that the transparent test tube 6 is automatically immersed in or out of the water bath environment;

[0072...

Embodiment 2

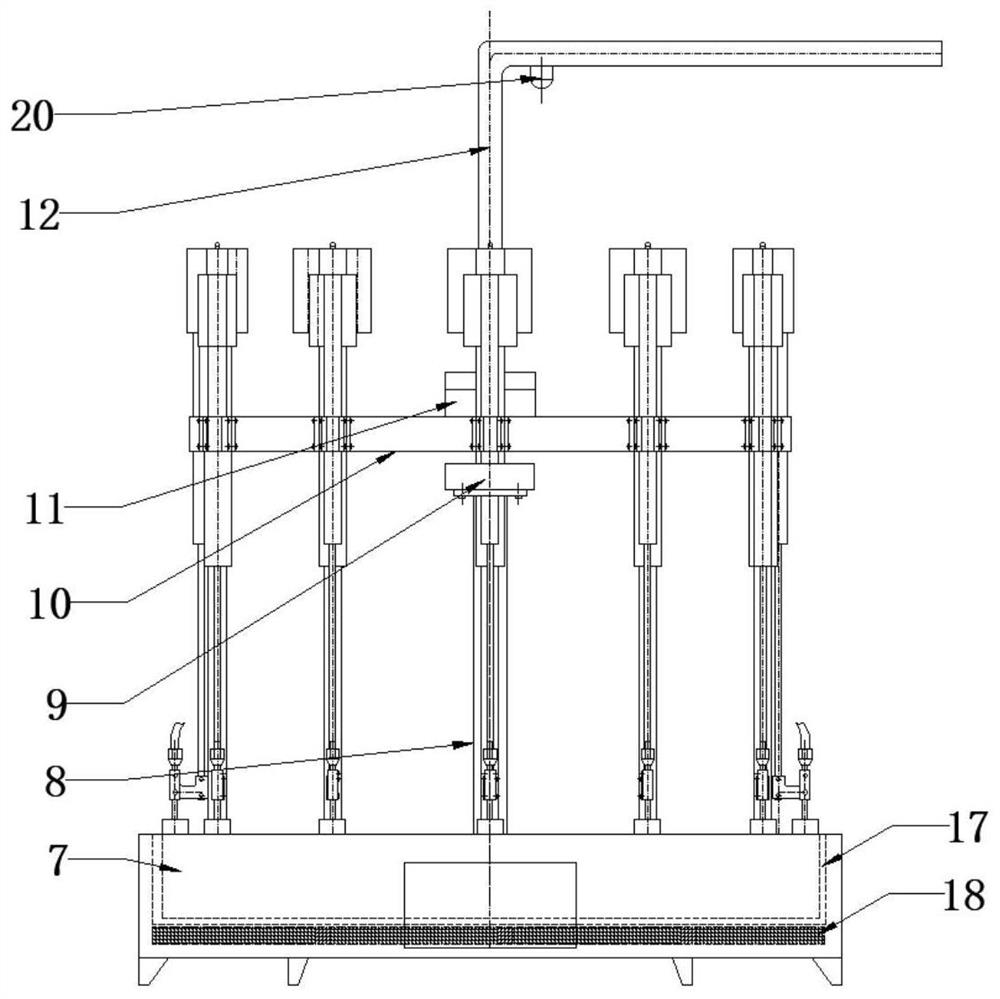

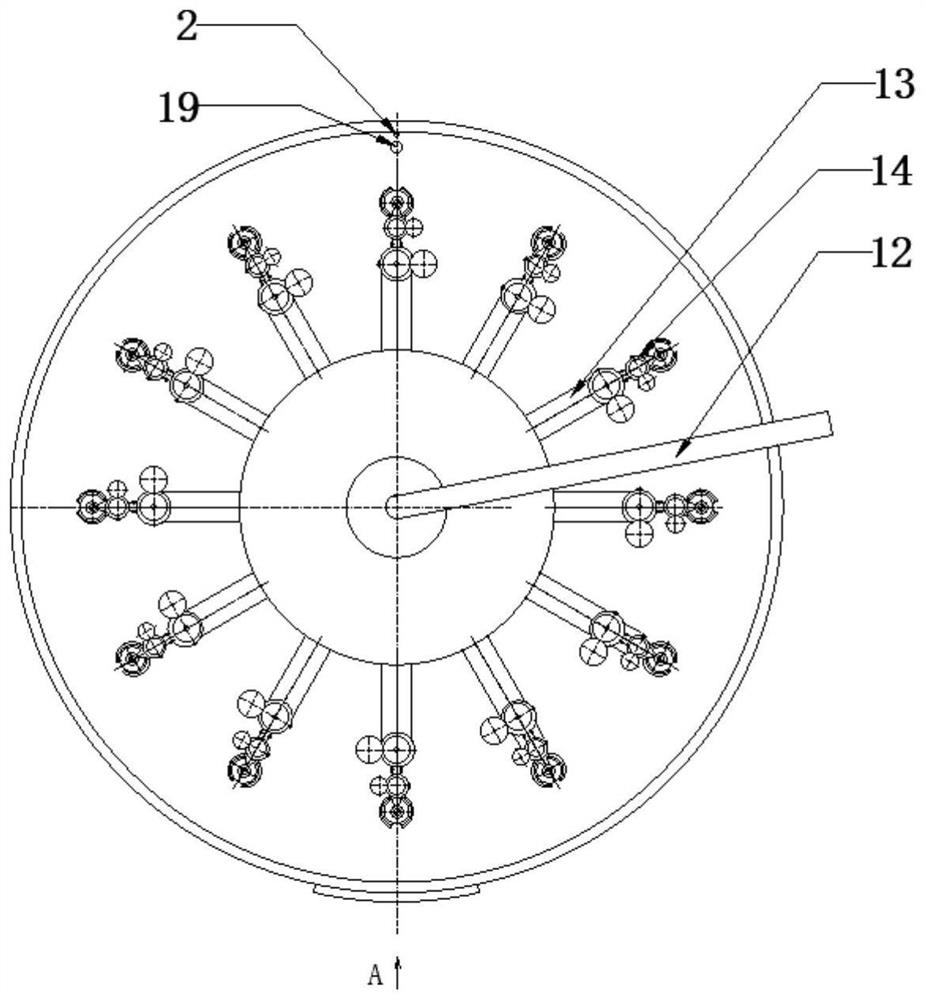

[0074] On the basis of Embodiment 1, a supporting mechanism is added, and the supporting mechanism includes a base 7, a vertical column 8, a vertical servo motor 9, a horizontal circular tray 10, a gas-electric slip ring 11 and a gas-electric sheath tube 12, and the vertical column 8 Be arranged at the center of described base 7, be provided with a vertical servomotor 9 at the top of vertical column 8, described horizontal round tray 10 is fixed on the top of vertical servomotor 9 motor shafts, is installed in the center of described horizontal round tray 10 top surfaces. There is a gas-electric slip ring 11, and the gas-electric slip ring 11 is connected to the gas-electric sheath pipe 12 on the top of the gas-electric slip ring. The electric control circuit is arranged inside the gas-electric sheath pipe 12. The horizontal circular tray 10 Horizontal rods 13 are arranged on the circumference of each horizontal rod 13, and double snap rings 14 are installed on the outer ends o...

Embodiment 3

[0076]A gas supply system is added to the technology of embodiment two, and the gas supply system includes a nitrogen main pipeline and a nitrogen branch 15; a miniature electromagnetic shut-off valve and an electronically controlled pressure regulating valve are installed on the nitrogen branch 15, and the miniature The electromagnetic cut-off valve and the electric control pressure regulating valve are connected with the main nitrogen pipeline through pipelines, and the main electric control shut-off valve and the total electric control pressure regulating valve are installed on the nitrogen main pipeline, and the main nitrogen pipeline passes through the gas-electric slip ring 11 is connected with each nitrogen branch 15; preferably, the nitrogen branch 15 is connected with the nitrogen blow pipe 5 through a tightening nut 16; The electric control wires of the total pressure regulating valve are all connected with the control system, and are used to control the nitrogen blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com