Reverse osmosis strong brine concentration method and equipment

A technology of concentrated brine and reverse osmosis, applied in chemical instruments and methods, reflux water treatment, water/sewage treatment, etc., can solve problems such as difficulty in starting up for the first time, large power consumption, heat loss, etc., and achieve easy automatic control and reduce concentration cost and reduce overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

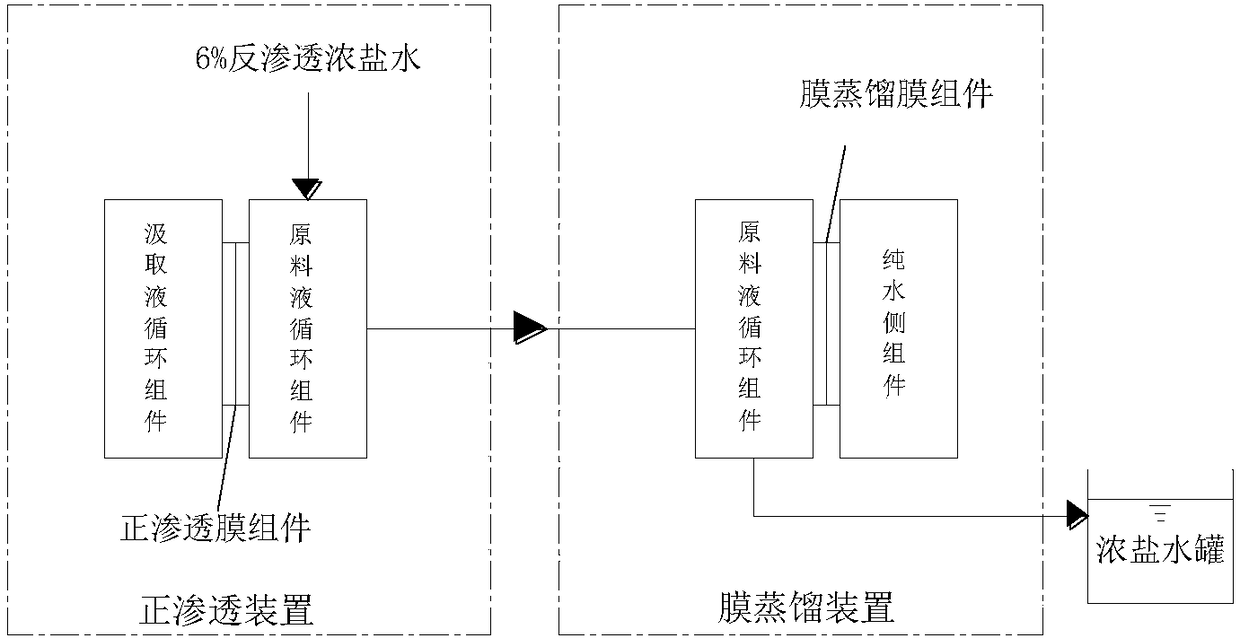

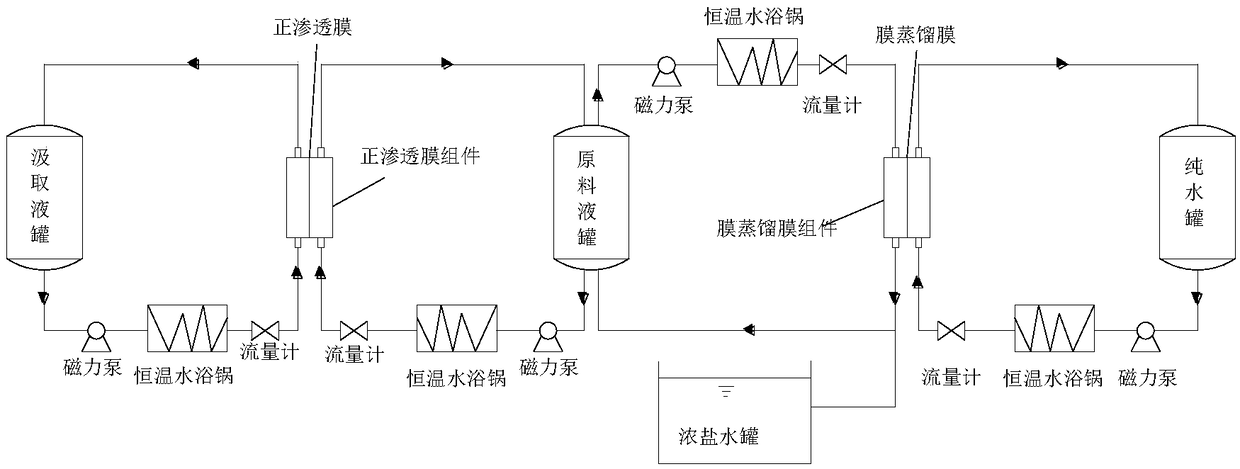

[0030] use figure 2 For the concentration equipment shown, the raw material liquid of the forward osmosis device is the above-mentioned 6% reverse osmosis concentrated brine, and the drawing liquid is 3M MgCl 2 solution, the membrane is a polyethersulfone membrane, and the orientation of the membrane is FO mode; the membrane distillation device is a direct contact membrane distillation, the membrane adopts a polyvinylidene fluoride flat membrane, and the raw material solution is reverse osmosis concentrated brine that has been concentrated by forward osmosis.

[0031] First, 6% reverse osmosis concentrated brine is pumped out of the raw material liquid tank with a circulating water pump through a constant temperature heating device at 25°C-35°C, and the flow rate is adjusted to 80L / h through a flow meter, and then sent to the raw material liquid side of the forward osmosis membrane module Circulation; at the same time, the draw liquid is pumped out from the draw liquid tank w...

Embodiment 2

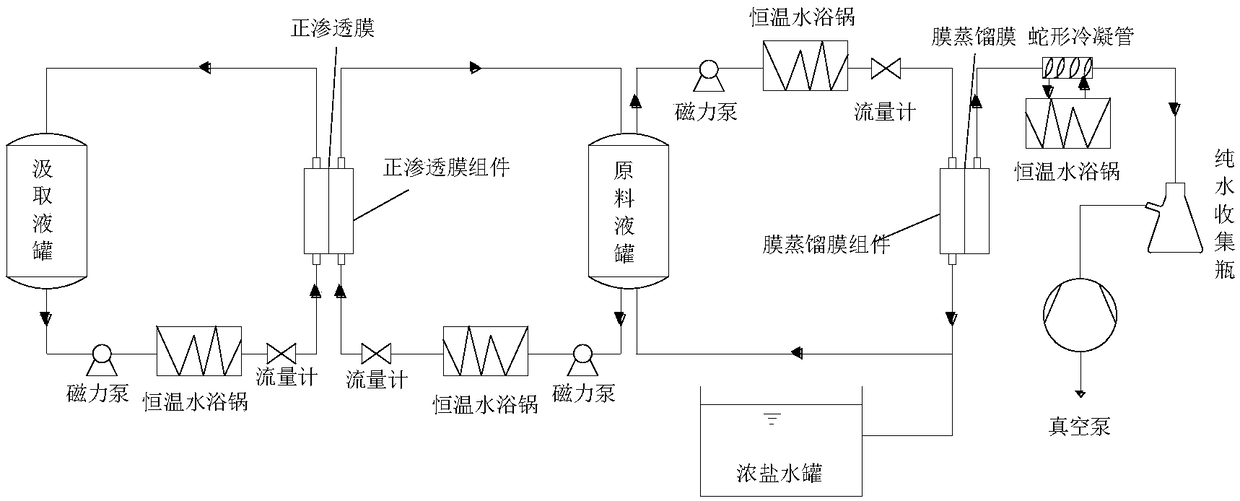

[0035] use image 3 For the concentration equipment shown, the raw material liquid of the forward osmosis device is the above-mentioned 6% reverse osmosis concentrated brine, and the drawing liquid is 3M MgCl 2 solution, the membrane is polyethersulfone membrane, and the orientation of the membrane is FO mode; the membrane distillation device is vacuum membrane distillation, and the membrane adopts polyvinylidene fluoride flat membrane, and the raw material solution is reverse osmosis concentrated brine that has been concentrated by forward osmosis.

[0036] First, 6% reverse osmosis concentrated brine is pumped out of the raw material liquid tank with a circulating water pump through a constant temperature heating device at 25°C-35°C, and the flow rate is adjusted to 80L / h through a flow meter, and then sent to the raw material liquid side of the forward osmosis membrane module Circulation; at the same time, the draw liquid is pumped out from the draw liquid tank with a circu...

Embodiment 3

[0041] use figure 2 For the concentration equipment shown, the raw material liquid of the forward osmosis device is the above-mentioned 6% reverse osmosis concentrated brine, and the drawing liquid is 3M MgCl 2 The solution, the membrane is a polysulfone membrane, and the orientation of the membrane is FO mode; the membrane distillation device is a direct contact membrane distillation, and the membrane adopts a polyvinylidene fluoride flat membrane, and the raw material solution is reverse osmosis concentrated brine that has been concentrated by forward osmosis.

[0042] First, 6% reverse osmosis concentrated brine is pumped out of the raw material liquid tank with a circulating water pump through a constant temperature heating device at 25°C-35°C, and the flow rate is adjusted to 80L / h through a flow meter, and then sent to the raw material liquid side of the forward osmosis membrane module Circulation; at the same time, the draw liquid is pumped out from the draw liquid tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com