Device and method for separating and purifying by-products in epichlorohydrin wastewater

A technology for epichlorohydrin and by-products is applied in the field of devices for separating and purifying by-products in epichlorohydrin wastewater, which can solve the problems of inability to achieve resource utilization and high treatment costs, and achieve resource utilization, The effect of low energy consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

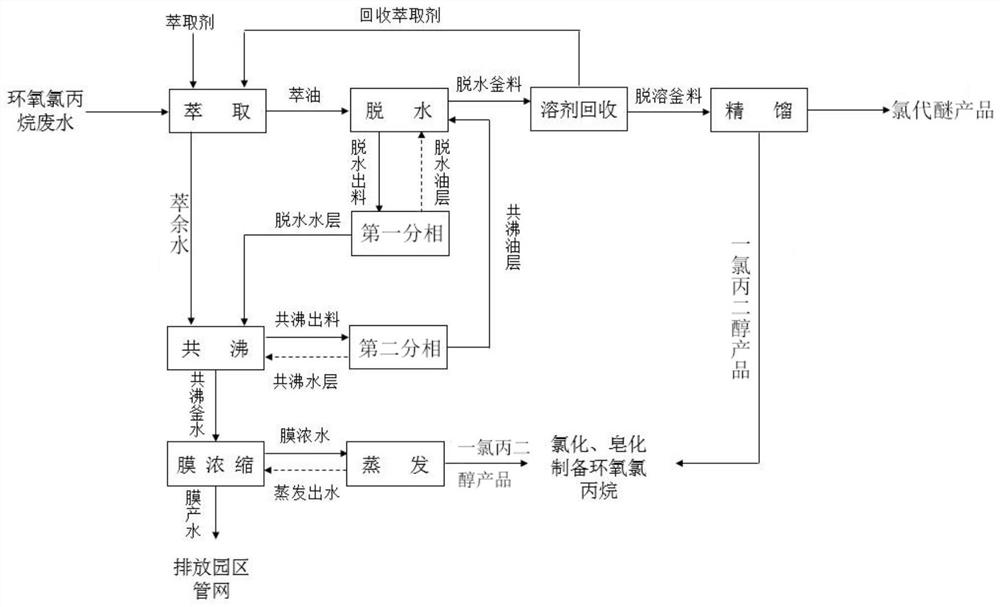

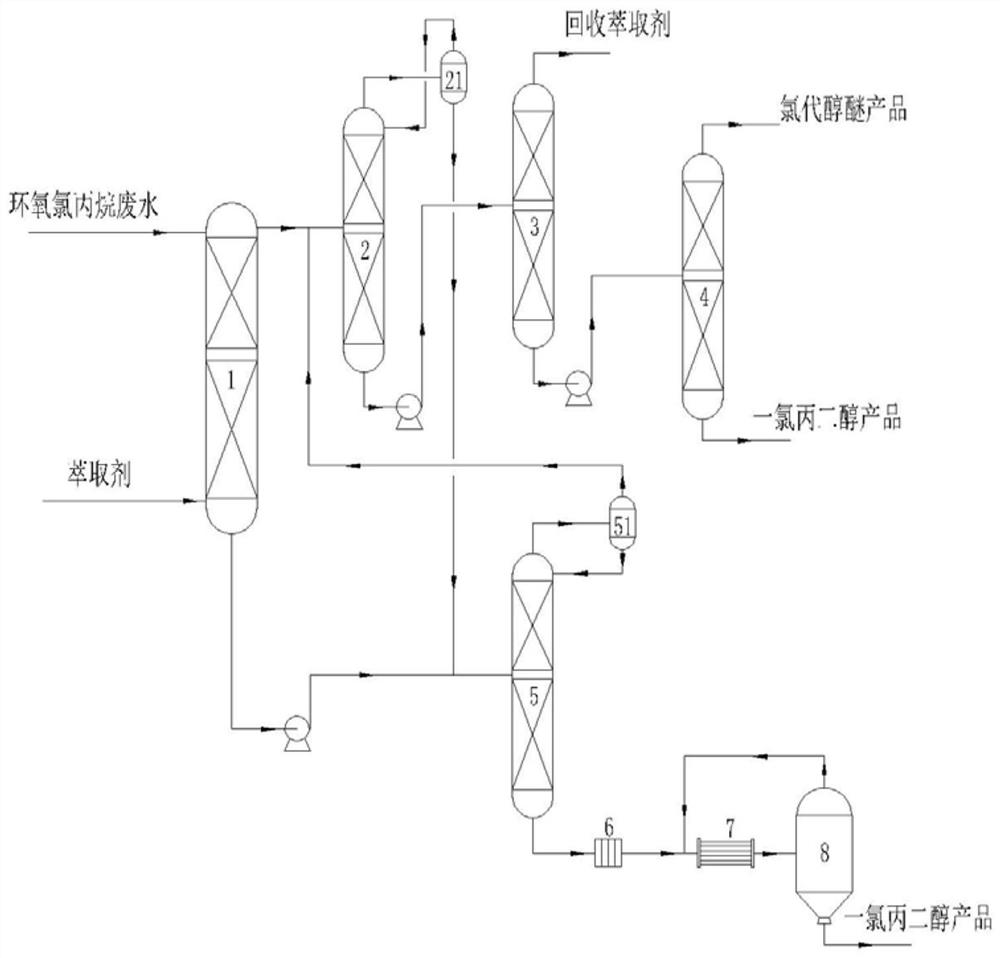

[0093] This embodiment provides a device for separating and purifying by-products in epichlorohydrin wastewater, such as figure 2As shown, the device includes an extraction unit, a dehydration unit, a solvent recovery unit and a rectification unit connected in sequence; the device also includes an azeotrope unit, a membrane concentration unit and an evaporation unit 8 connected in sequence with the extraction unit.

[0094] The extraction unit includes an extraction tower 1; the dehydration unit includes a dehydration tower 2; the top of the dehydration tower 2 is provided with a first phase separation device 21; the first phase separation device 21 includes a dehydration oil layer outlet and a dehydration water layer outlet The dehydration oil layer outlet is connected to the dehydration tower 2; the dehydration water layer outlet is connected to the azeotropic unit; the solvent recovery unit includes a solvent recovery tower 3; the rectification unit includes a rectification...

Embodiment 2~5

[0106] On the basis of Example 1, isobutanol, anisole, n-butyl acetate, and dichloromethane were respectively selected as extraction agents, and the test results are shown in Table 1.

[0107] Table 1

[0108]

Embodiment 6~10

[0110] On the basis of Example 1, the weight ratios of the extractant to the adjusted wastewater were 0.1:1, 0.3:1, 0.5:1, 0.05:1 and 1:1, respectively. The test results are shown in Table 2.

[0111] Table 2

[0112]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com