Method for preparing titanium white powder from high-concentration additional crystal seeds

A technology of adding seed crystals and titanium dioxide, which is applied in the direction of chemical instruments and methods, titanium dioxide, titanium compounds, etc. Low washing efficiency of titanic acid, etc., to achieve good economic and social benefits, save concentration costs, and excellent pigment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

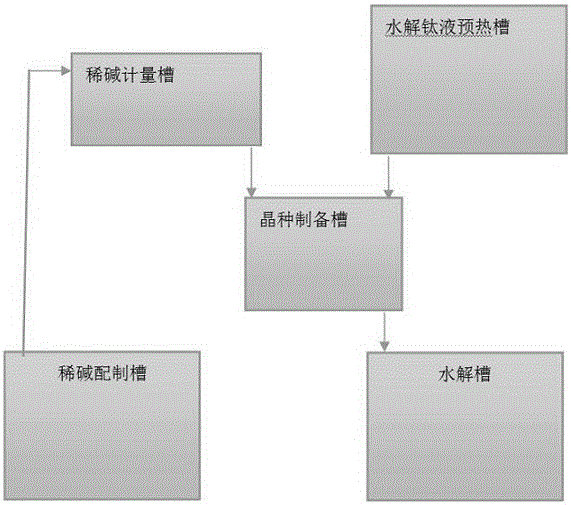

[0020] Adopt sulfuric acid method to produce titanium dioxide, wherein hydrolysis method comprises the following steps:

[0021] (1) Put a metered amount of 100±5g / L NaOH into the seed crystal preparation tank. When the hydrolyzed titanium solution is preheated to 77-80°C, turn on the stirring and steam valve of the seed crystal preparation tank, and then preheat the alkali solution Heat to 85°C; when the preheating temperature of the hydrolyzed titanium solution reaches 85°C, open the titanium liquid discharge valve of the hydrolyzed titanium liquid preheating tank and add the titanium liquid to the seed preparation tank, and control the opening of the discharge valve so that the hydrolyzed titanium liquid is uniform Add seed crystal preparation tank and mix with lye;

[0022] After adding the hydrolyzed titanium solution, close the discharge valve of the hydrolyzed titanium solution, open the steam valve of the seed crystal preparation tank at the same time, raise the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com