Processing method of casting zinc dross

A treatment method and technology for zinc scum, applied in the direction of improving process efficiency, can solve problems such as pollution of the environment, and achieve the effects of environmental protection and high zinc recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

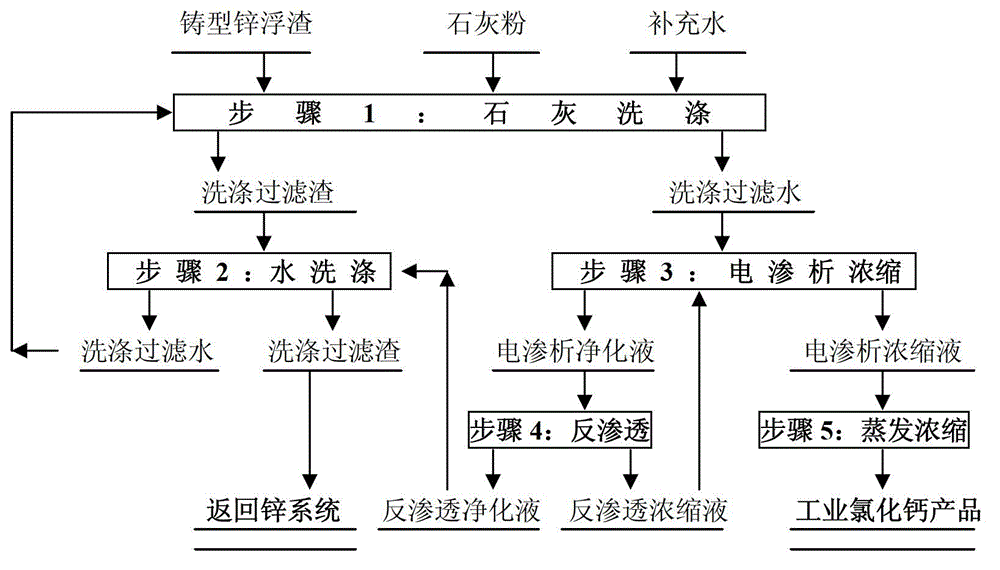

[0022] This embodiment is the first example of the method for processing zinc dross in the present invention, and includes the following steps:

[0023] (1) Lime water washing: Add 18 cubic meters of water into a 30 cubic meter washing tank, stir at 25°C, and add 6 tons of cast zinc scum with 70% zinc and 1.0% chlorine. Use 81 kilograms of slaked lime powder, adjust the end pH of the washing liquid to 9, wash for 10 minutes, and filter and separate to obtain 16.5 cubic meters of lime water washing filtrate with a chlorine content of 3.1 g / L and lime water with a chlorine content of 0.35%. 7.7 tons of wet residue.

[0024] (2) Tap water washing: In a 30 cubic meter washing tank, add 18 cubic meters of tap water, stir, add lime water to wash and filter 7.7 tons of wet residue, wash at a temperature of 25°C for 10 minutes, filter and separate to obtain The tap water with 0.12% chlorine washes and filters 7.7 tons of wet residue and 18 cubic meters of washing and filtration water; the...

no. 2 example

[0029] This embodiment is the second example of the method for processing zinc dross in the present invention, which includes the following steps:

[0030] (1) Lime water washing: Add 25 cubic meters of water to a 30 cubic meter washing tank, stir, and the temperature is 25°C. Add 6 tons of cast zinc scum with 78% zinc and 2.0% chlorine. Use 164 kg of slaked lime powder, adjust the end pH of the washing liquid to 10, wash for 20 minutes, and filter and separate to obtain 23.5 cubic meters of lime water washing filtrate with chlorine 5.0 g / l and lime water with 0.46% chlorine. Wet slag is 7.6 tons.

[0031] (2) Tap water washing: In a 30 cubic meter washing tank, add 25 cubic meters of tap water, stir, add lime water to wash the filtered wet residue 7.6 tons, wash at a temperature of 25 ℃ for 20 minutes, filter and separate to obtain The tap water with 0.11% chlorine washes and filters 7.6 tons of wet residue and 25 cubic meters of washing and filtration water; the washing and filt...

Embodiment 3

[0036] This embodiment is the second example of the method for processing zinc dross in the present invention, which includes the following steps:

[0037] (1) Lime water washing: Add 25 cubic meters of water into a 30 cubic meter washing tank, stir, and the temperature is 25°C. Add 5 tons of cast zinc scum with 85% zinc and 3.0% chlorine. Use 206 kg of slaked lime powder, adjust the end pH of the washing liquid to 11, wash for 30 minutes, and filter and separate to obtain 23.6 cubic meters of lime water washing filtrate with a chlorine content of 6.0 g / l and a lime water with 0.58% chlorine. Wet slag is 6.4 tons.

[0038] (2) Tap water washing: In a 30 cubic meter washing tank, add 25 cubic meters of tap water, stir, add lime water to wash and filter 6.4 tons of wet residue, wash at a temperature of 25°C for 30 minutes, filter and separate to obtain The tap water with 0.13% chlorine washes and filters 6.4 tons of wet residue and 25 cubic meters of washing and filtered water; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com