Dilute sulfuric acid vacuum concentration device and method

A technology of sulfuric acid concentration and vacuum concentration, which is applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of high reliability requirements, and achieve the effects of good corrosion resistance, energy saving and electricity consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

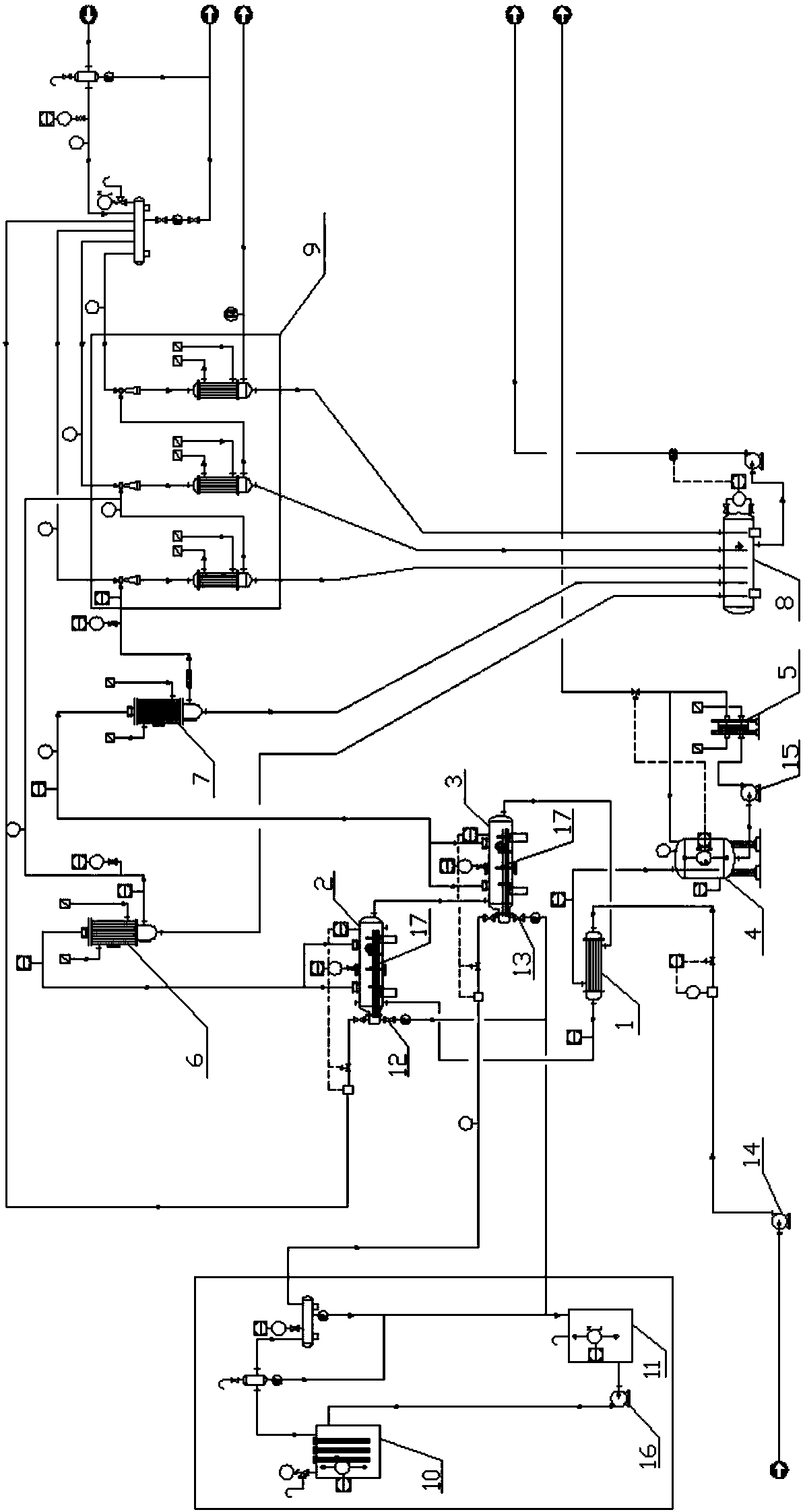

[0035] refer to figure 1 , a dilute sulfuric acid vacuum concentration device, said device includes an acid-acid heat exchanger 1, a primary sulfuric acid concentration tank 2, a secondary sulfuric acid concentration tank 3, a concentrated sulfuric acid circulation tank 4, a circulating concentrated sulfuric acid cooler 5, a primary tail gas Condenser 6, secondary tail gas condenser 7, waste water collection tank 8, multi-stage steam jet vacuum pump unit 9, electric heating steam generating boiler 10 and steam condensed water circulation tank 11, the acid-acid heat exchanger 1 is concentrated with the primary sulfuric acid Groove 2 is connected, and described primary sulfuric acid concentration tank 2 is connected with secondary sulfuric acid concentration tank 3, and described secondary sulfuric acid concentration tank 3 is connected with acid-acid heat exchanger 1, and described acid-acid heat exchanger 1 is connected with The concentrated sulfuric acid circulation tank 4 is...

Embodiment 2

[0046] Refer to Example 1 for the dilute sulfuric acid vacuum concentration device.

[0047] refer to figure 1 , a dilute sulfuric acid vacuum concentration method, comprising the steps of:

[0048] (1) The 75% dilute sulfuric acid clear liquid enters the acid-acid heat exchanger 1 after being pressurized and metered by the dilute sulfuric acid feeding pump 14, and uses the secondary sulfuric acid concentration tank 3 to discharge the residual heat of high-temperature concentrated sulfuric acid to preheat the raw material dilute acid, and then enters a Stage sulfuric acid concentration tank 2. Under vacuum conditions, the acid liquid in multiple concentration chambers in the concentration tank boils and evaporates at a lower temperature, and the concentration increases step by step. The maximum average temperature difference between the acid liquid and the heating tube makes full use of the heating area on the surface of the tantalum tube, so that the sulfuric acid flowing ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com