Adipic acid waste water evaporation and concentration process and device thereof

A technology of evaporative concentration and adipic acid, applied in natural water treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve environmental pollution, non-environmental protection and other problems, reduce pollution and save energy consumption , The effect of reducing the cost of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

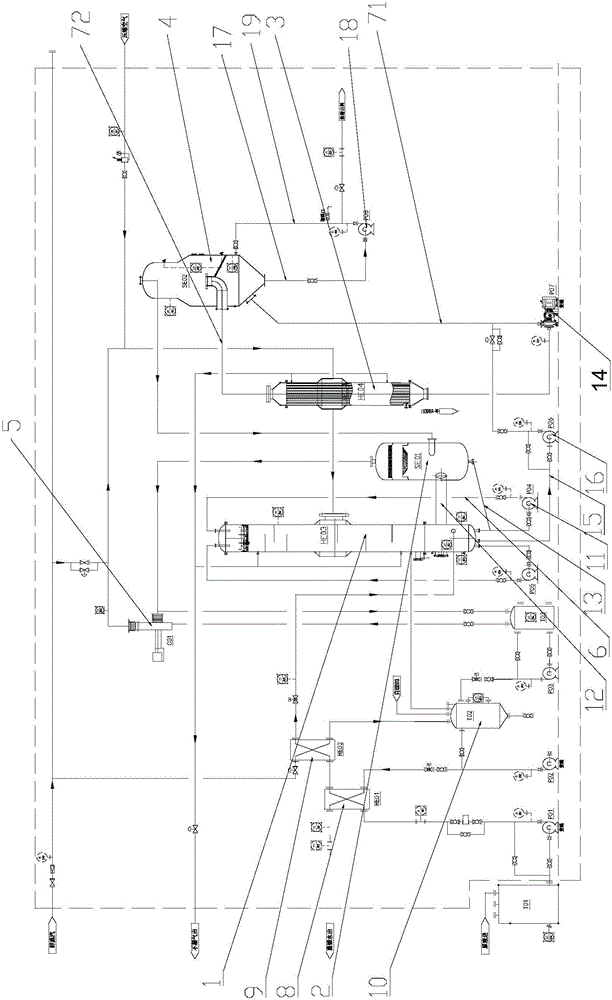

[0024] Adipic acid waste water evaporation concentration process is characterized in that: comprises the following steps,

[0025] Step 1, preheating the material;

[0026] Step 2. The preheated material enters the falling film heat exchanger for heating to form a gas-liquid mixture;

[0027] Step 3, the gas-liquid mixture enters the falling film separator for gas-liquid separation, and the concentrated liquid returns to the falling film heat exchanger;

[0028] Step 4: After the concentration ratio of the material in the falling film heat exchanger reaches the preset value, it is transferred out, and after being heated by the forced circulation heat exchanger, it is sent to the gas-liquid separator for further gas-liquid separation. Otherwise, the material is heated in the falling film heat exchanger. Repeat step 3 after heating in the container;

[0029] Step 5: After the material is further concentrated in the gas-liquid separator, when the concentration ratio meets the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com