Method for utilizing critic acid fermentation wastewater

A technology for fermenting waste water and citric acid, applied in the field of environmental engineering, can solve the problems of complex technical process, environmental pollution and high production cost, and achieve the effects of good effect, reduction of concentration cost and reduction of treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

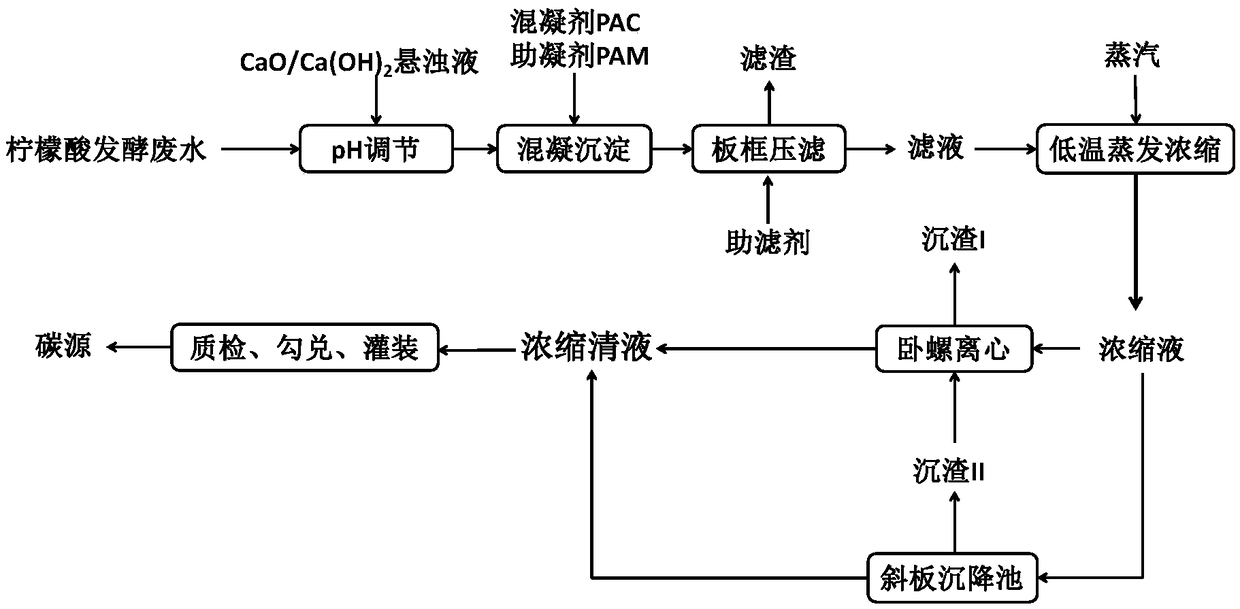

[0030] This embodiment is accomplished by the following steps:

[0031] (1) Add 30% (w / w) CaO suspension and coagulant PAC

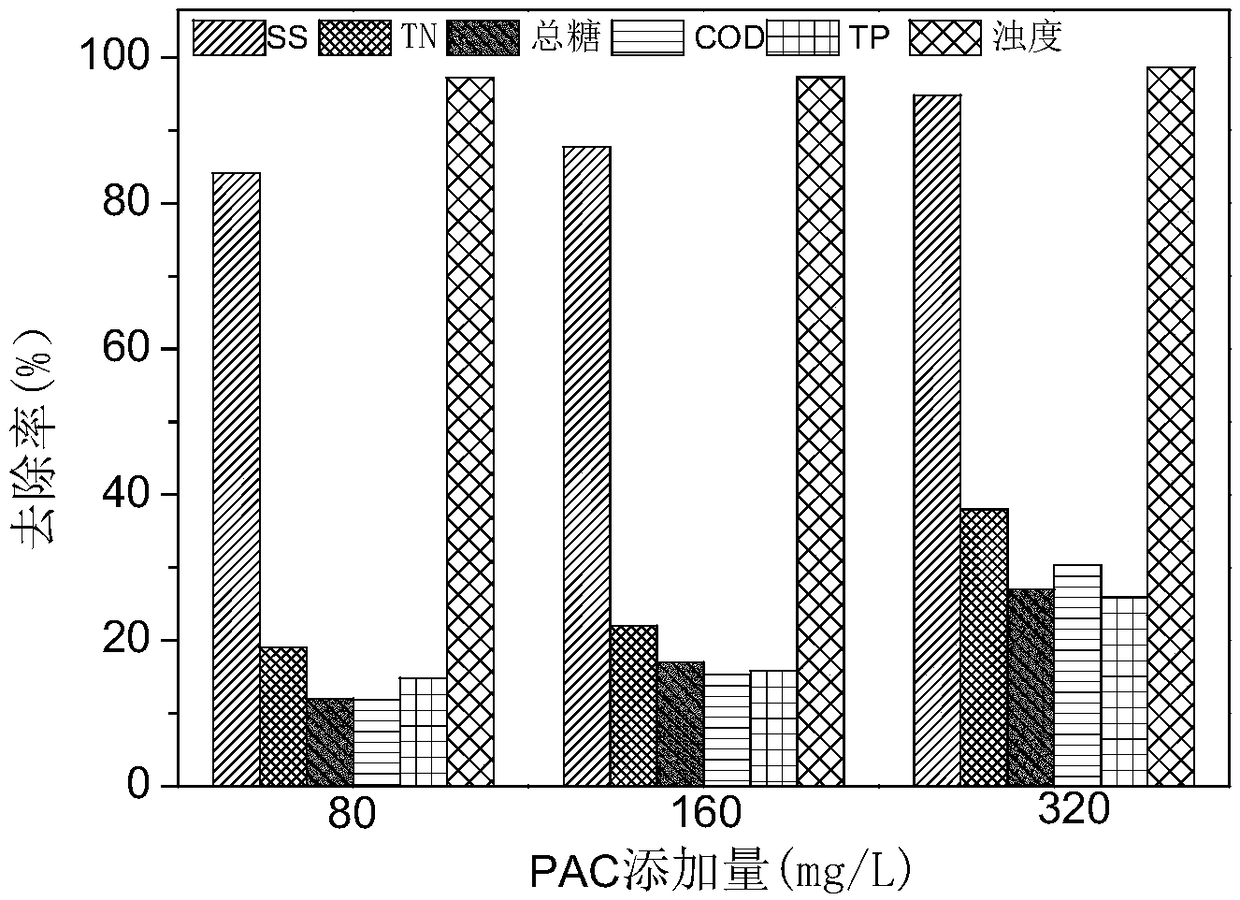

[0032] Take 7m 3 The citric acid fermentation waste liquid was placed in the pilot test reaction tank, and 30% (w / w) CaO suspension was added to adjust the pH to be stable at 8.0, while stirring while flowing, and a concentration of 100g / L coagulant PAC solution 5.6 was added. L, stirred for 20 minutes, free sedimentation for 20 minutes, and left to react for 1.5 hours. See figure 2 .

[0033] The data shows that: when the PAC flow rate is 80mg / L, 160mg / L, and 320mg / L in turn, although the suspended solids (SS), COD, and total phosphorus (TP) of the filtrate obtained in step (2) plate and frame pressure filtration , TN and other indicators increased in turn, but the improvement effect of each indicator removal rate was not obvious. Considering the economic cost, the optimal PAC flow rate was finally determined to be 80mg / L.

[0034] (2) The first s...

Embodiment 2

[0057] The difference between this embodiment and Example 1 is that the 30% (w / w) CaO suspension described in step (1) is changed to 30% (w / w) Ca(OH) 2 Suspension. The content and removal rate of each index before and after plate and frame filtration of citric acid fermentation wastewater are shown in Table 1, and the content of each index of supplementary carbon source is shown in Table 2.

Embodiment 3

[0059] The difference between this embodiment and Example 1 is that the solid-liquid separation process described in step (4) is changed from a decanter centrifugal process to an inclined plate sedimentation tank separation process; the dilution factor of the supplementary carbon source described in step (6) is changed to 1500 times. The content and removal rate of each index before and after plate and frame filtration of citric acid fermentation wastewater are shown in Table 1, and the contents of each index of supplemented carbon source are shown in Table 4.

[0060] Table 4 The content of each index of supplementary carbon source in Example 3

[0061] Test items

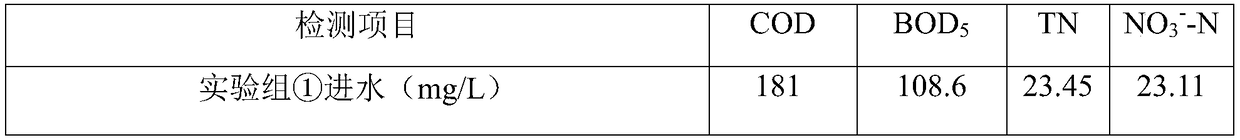

[0062] The content and removal rate of each index in the experimental group ② influent and effluent are shown in Table 3; the experimental group ① influent index: COD is 190.2mg / L, BOD 5 114.2mg / L, TN 24.09mg / L, NO 3 - -N is 23.67mg / L; the experimental group ① effluent index: COD is 45.2mg / L, BOD 5 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com