Process for removing impurities from lepidolite leaching solution

A technology of leaching solution and lepidolite, applied in the field of ore extraction of lithium, can solve the problems of high cost of impurity removal, low total recovery rate of lithium, low value of residual slag from impurity removal, etc., and achieves low cost of impurity removal, low concentration cost, The effect of less cleaning agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

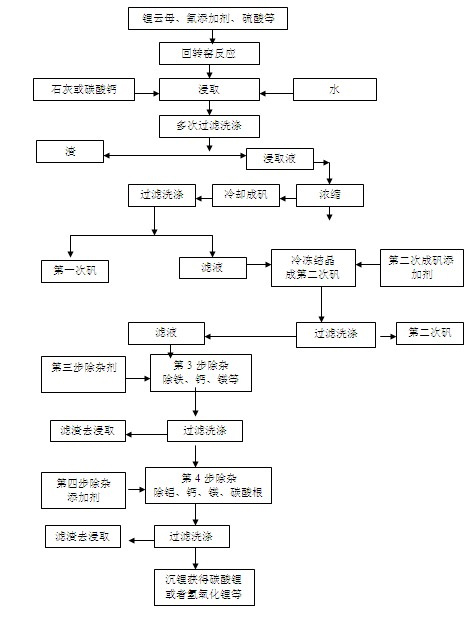

Image

Examples

Embodiment 1

[0038] A lepidolite leaching liquid impurity removal process is 2 times of forming alum and removing impurities, and 2 times of adjusting the pH value to remove impurities. The specific steps are:

[0039] 1) After the leaching solution is concentrated, it is cooled and crystallized into alum, and filtered to obtain the first alum and the first alum filtrate;

[0040] 2) Add additives to the first alum forming filtrate, continue to cool to form alum, or concentrate and then cool and crystallize to form alum. After the crystallization is completed, filter to obtain the second alum and the second alum forming filtrate respectively;

[0041] 3) The second alum-forming filtrate is added for the third time by adding a pH-adjusting impurity remover to remove magnesium, calcium, iron, and manganese ion impurities in the solution, and then filter to obtain the filtrate and precipitate, and the precipitate returns to the leaching step or abandoned;

[0042] 4) Add the filtrate in...

Embodiment 2

[0052] A lepidolite leaching liquid impurity removal process is 2 times of forming alum and removing impurities, and 2 times of adjusting the pH value to remove impurities. The specific steps are:

[0053] 1) After the leaching solution is concentrated, it is cooled and crystallized into alum, and filtered to obtain the first alum and the first alum filtrate;

[0054] 2) Add additives to the first alum forming filtrate, continue to cool to form alum, or concentrate and then cool and crystallize to form alum. After the crystallization is completed, filter to obtain the second alum and the second alum forming filtrate respectively;

[0055] 3) The second alum-forming filtrate is added for the third time by adding a pH-adjusting impurity remover to remove magnesium, calcium, iron, and manganese ion impurities in the solution, and then filter to obtain the filtrate and precipitate, and the precipitate returns to the leaching step or abandoned;

[0056] 4) Add the filtrate in step...

Embodiment 3

[0066] A lepidolite leaching liquid impurity removal process is 2 times of forming alum and removing impurities, and 2 times of adjusting the pH value to remove impurities. The specific steps are:

[0067] 1) After the leaching solution is concentrated, it is cooled and crystallized into alum, and filtered to obtain the first alum and the first alum filtrate;

[0068] 2) Add additives to the first alum forming filtrate, continue to cool to form alum, or concentrate and then cool and crystallize to form alum. After the crystallization is completed, filter to obtain the second alum and the second alum forming filtrate respectively;

[0069] 3) The second alum-forming filtrate is added with a pH regulator for the third impurity removal to remove magnesium, calcium, and iron ion impurities in the solution, and filtered to obtain the filtrate and precipitate, and the precipitate is returned to the leaching step or discarded;

[0070] 4) Add the filtrate in step 3) to the pH regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com