Lead fume purifier in lead-acid storage battery industry and purification method of lead fume purifier

A lead-acid battery, purifier technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of short service life, inclusion of lead ions, affecting the effect of environmental protection testing and testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

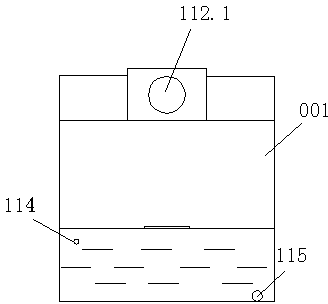

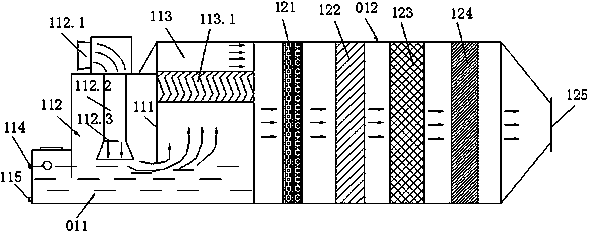

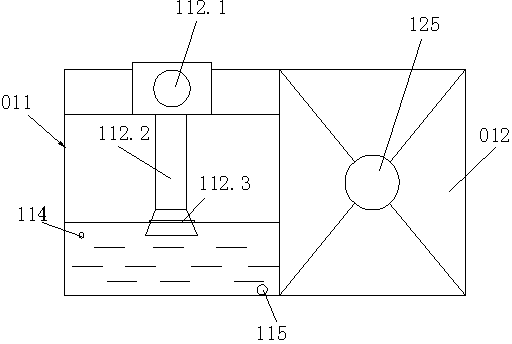

[0019] Example 1: A lead fume purifier for the lead-acid storage battery industry, including a housing 001, the inner cavity of which is composed of a water bath fire resistance chamber 011 and an adsorption filter chamber 012, both of which are arranged in a straight line, and the water bath resistance The fire chamber 011 includes two left and right chambers (112, 113) separated by a partition 111. The lower parts of the two chambers (112, 113) are connected and filled with water bath liquid. The top of the left chamber 112 has an air inlet 112.1, the air inlet 112.1 is connected with an air inlet pipe 112.2 extending into the inner cavity of the water bath fire retardant chamber 011 close to the surface of the water bath liquid, the end of the partition 111 is close to the surface of the water bath liquid, and the bottom of the water bath fire retardant chamber 011 is provided with a water inlet 114 and a bottom Sewage outlet 115, the right chamber 113 is provided with a deh...

Embodiment 2

[0020] Embodiment 2, referring to Embodiment 1, the water-bath fire-resistance chamber 011 and the adsorption filter chamber 012 are arranged in an L shape, and the chamber above the dehydration baffle 113.1 is provided with a pipeline that communicates with the chamber of the primary filter material adsorption section 121.

[0021] In the above two embodiments, the windshield can also be installed at the end of the partition close to the liquid surface of the water bath, and the speed at which the airflow hits the liquid surface can be controlled by adjusting the angle of the windshield.

Embodiment 3

[0022] Embodiment 3: A purification method for lead fume purifiers in the lead-acid storage battery industry, characterized in that it comprises the following steps: first, the flue gas is passed through the air inlet, and the speed at which the airflow hits the liquid surface is controlled at 5 to 8 through the windshield. Within the range of m / s, the airflow after hitting the water surface hits the S-shaped defogging baffle at a speed of ≤1.5 m / s, and the gas purified by the primary filter material passes through the activated carbon filter layer at a speed of ≤2 m / s Cross-section, the gas after the activated carbon filter layer passes through the second-stage filter material filter with a purification level of F5-F9 again, and finally is composed of H13-H15 of HEPA level or U15-U17 of ULPA level. After being filtered by the frame-type high-efficiency filter, it is discharged through the air outlet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com