Hydrogen fuel cell tail gas recovery treatment system and method

A fuel cell and tail gas recovery technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of unconsidered influence, mixing, and inability to ensure complete separation of hydrogen, oxygen, and water vapor, and achieve improved Fuel efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

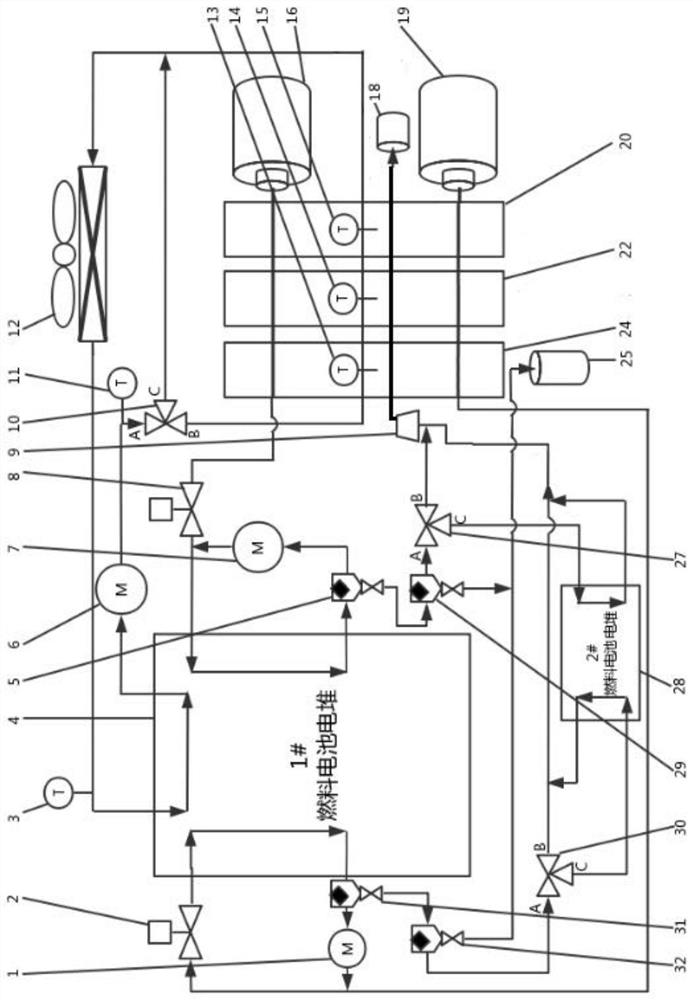

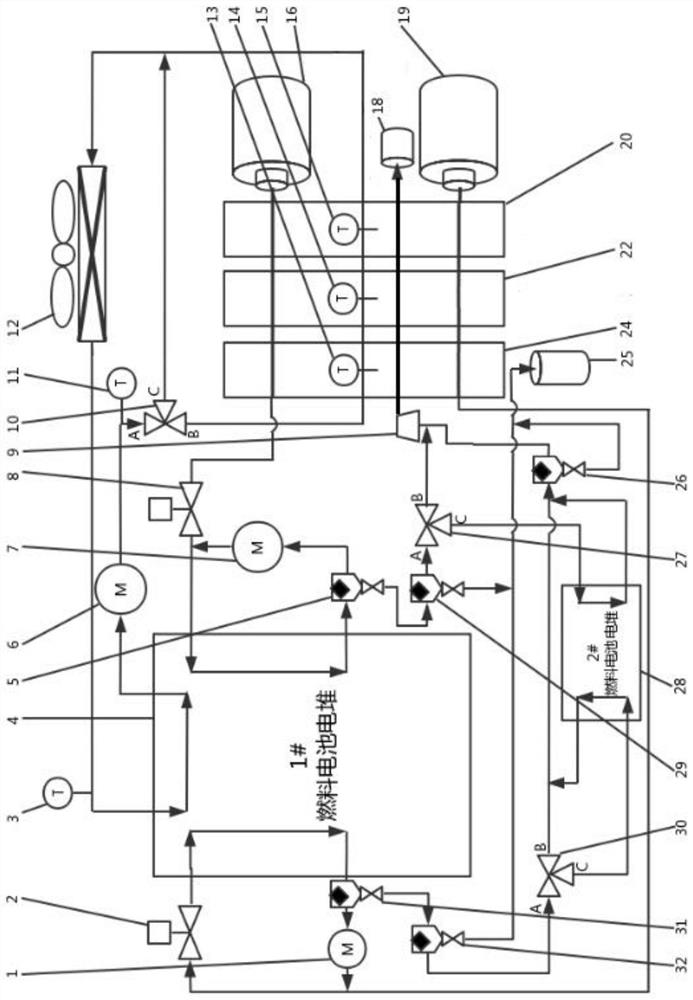

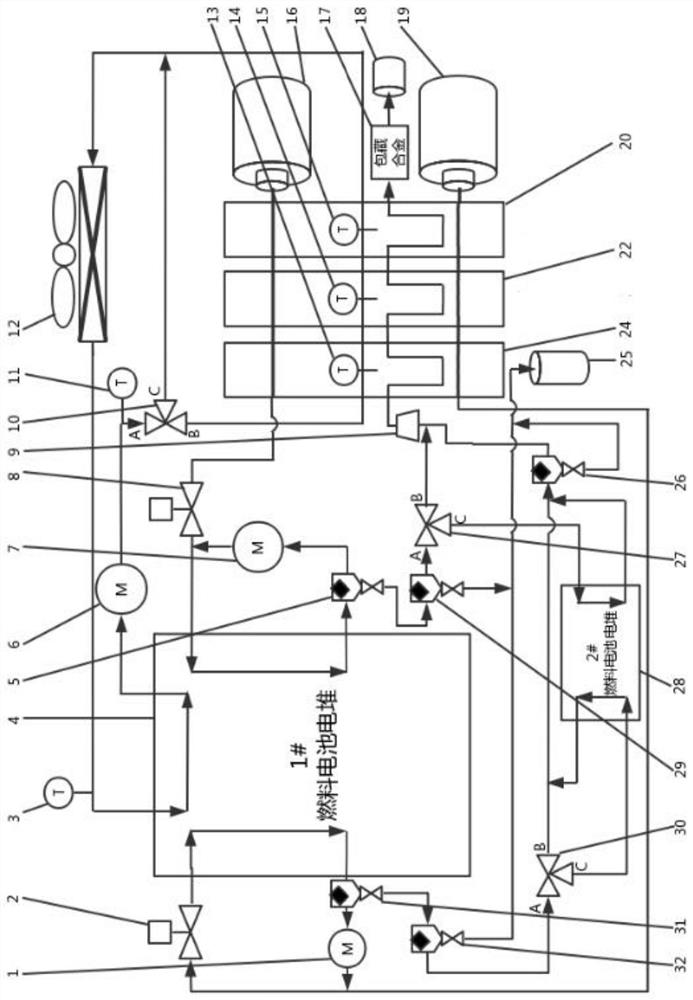

[0037] In this example, see figure 1 As shown, the present invention proposes a hydrogen fuel cell tail gas recovery treatment system, including a hydrogen pipeline unit, an oxygen pipeline unit, a temperature control pipeline unit, No. 1 heat exchanger 24, No. 2 heat exchanger 22, No. 3 heat exchanger Heat exchanger 20, No. 1 fuel cell stack 4, No. 2 fuel cell stack 28, gas compressor 9, water storage tank 25 and gas storage bottle 18;

[0038] The hydrogen pipeline unit includes liquid hydrogen tank 16, hydrogen regulating valve 8, No. 3 water vapor separator 5, hydrogen circulation pump 7, No. 4 water vapor separator 29 and No. 2 three-way valve 27; the outlet of liquid hydrogen tank 16 passes through No. 3 The hydrogen pipelines of heat exchanger 20, No. 2 heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com