E-level extra-thick high-intensity steel plate produced by using continuous casting billet and production method thereof

A technology of high-strength steel plate and production method, which is applied to the production of E-grade extra-thick high-strength steel plate by continuous casting slab and its production field, can solve the problems of increasing production cycle, complicated process and high cost, and achieve component saving, low cost, and low cost. The effect of production cost and cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

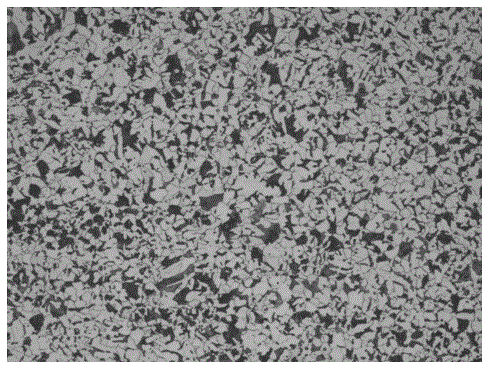

Image

Examples

Embodiment 1

[0034] Example 1 : The composition ratio and specific production process of this E-grade extra-thick high-strength steel plate are as follows.

[0035] The thickness of this steel plate is 190mm, and it is composed of the following components in weight percentage: C 0.16%, Si 0.35%, Mn 1.48%, P 0.015%, S 0.002%, Nb 0.024%, Alt 0.033%, and the balance is Fe and not Avoided impurities, CEV=0.42%.

[0036] The process steps of this high-strength steel plate production method are as follows: (1) Smelting and continuous casting process: the molten steel is first smelted in an electric furnace, and then transferred to LF refining. The whole process ensures good argon blowing. The Al line of the entire refining process is 450m, and the refining white slag is kept for a long time. 30min, lime consumption 16kg / t steel, total refining time 50min, process and slag removal Al ≥ 0.010%. After refining, transfer to VD furnace for vacuum degassing treatment, the vacuum holding time is 17m...

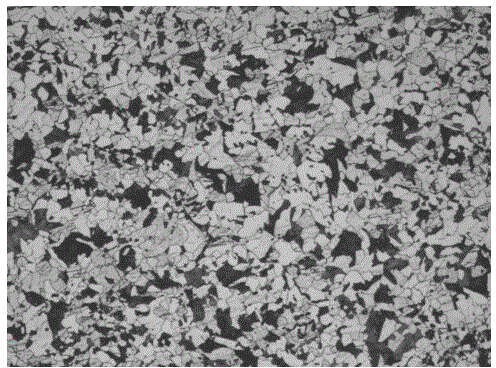

Embodiment 2

[0039] Example 2 : The composition ratio and specific production process of this E-grade extra-thick high-strength steel plate are as follows.

[0040] The thickness of this steel plate is 200mm, and it is composed of the following components in weight percentage: C 0.16%, Si 0.44%, Mn 1.50%, P 0.009%, S 0.010%, Nb 0.023%, Alt 0.020%, the balance is Fe and not Avoided impurities, CEV=0.42%.

[0041] The process steps of the high-strength steel plate production method are as follows: (1) smelting and continuous casting process: the smelting process is the same as that in Embodiment 1. During the continuous casting process, the degree of superheat is between 18-22°C, and the casting speed is 0.65m / min; the rear section of the continuous casting (9-11 section) is lightly reduced to 3.2mm, and a continuous casting slab with a thickness of 330mm is produced; after continuous casting Off-line stacking is slowly cooled, the stacking temperature is 830°C, and the stacking time is 2...

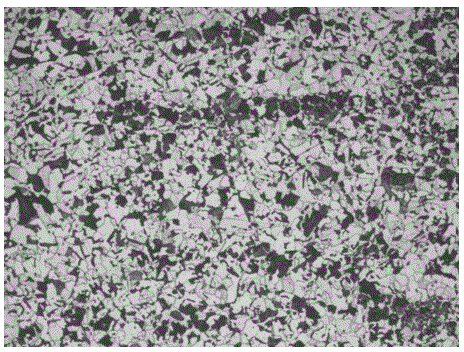

Embodiment 3

[0044] Example 3 : The composition ratio and specific production process of this E-grade extra-thick high-strength steel plate are as follows.

[0045] The thickness of this steel plate is 210mm, and it is composed of the following components in weight percentage: C 0.18%, Si 0.15%, Mn 1.48%, P 0.011%, S 0.015%, Nb 0.022%, Alt 0.050%, and the balance is Fe and not Avoided impurities, CEV=0.44%.

[0046] The process steps of the high-strength steel plate production method are as follows: (1) smelting and continuous casting process: the smelting process is the same as that in Embodiment 1. During the continuous casting process, the degree of superheat is 15-20°C, and the casting speed is 0.65m / min; the rear section of the continuous casting (9-11 section) is lightly reduced to 3.3mm to produce a continuous casting slab with a thickness of 330mm; The stacking is slowly cooled, the stacking temperature is 900°C, and the stacking time is 26h.

[0047] (2) Heating and rolling: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com