Low-cost 40CrV tool steel and production method thereof

A production method and low-cost technology, applied in the field of alloy structural steel, can solve problems such as performance stability, high uniformity requirements, fracture damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

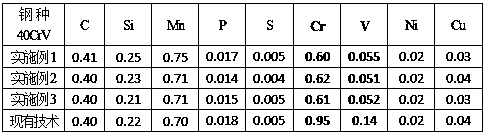

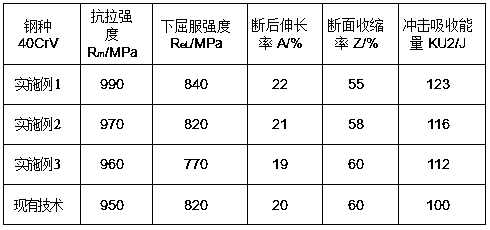

Examples

Embodiment 1~3

[0062] Select high-quality scrap steel, strictly prohibit the use of scrap steel containing high Cu, Pb and other harmful residual elements, and control Cu≤0.20%;

[0063] Before tapping, the alloy is added to the ladle for pre-baking;

[0064] Strictly control the composition of the steel, and strictly prohibit the slag from the steel;

[0065] Control the tapping temperature well, and strictly prohibit low-temperature tapping;

[0066] Strictly follow the process requirements to control the end point components to prevent molten steel from peroxidation;

[0067] 1) LD / EAF:

[0068] When tapping from LD or EAF, adjust the amount of aluminum cake according to the tapping carbon, and add 80-120Kg to each furnace;

[0069] 2) LF:

[0070] During LF smelting, alloy is added in the early stage of refining, and the slag surface is deoxidized at the same time; according to the S content at the station, the amount of lime in the slag material and the amount of refining slag in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com