Ultrahigh strength gas protection welding wire and manufacturing method thereof

A gas-shielded welding wire, ultra-high-strength technology, applied in the direction of manufacturing tools, welding media, welding equipment, etc., to achieve good welding performance, low production cost, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

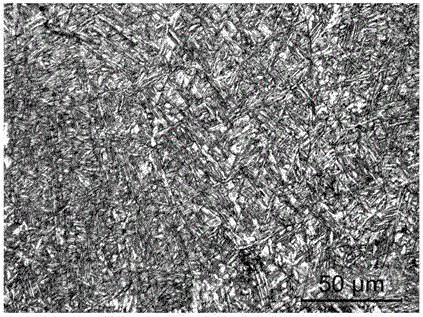

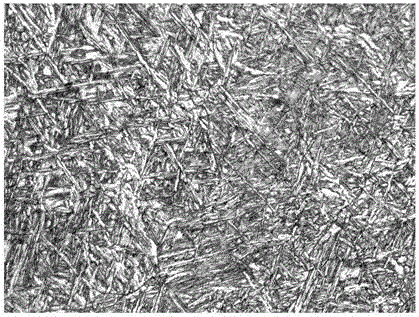

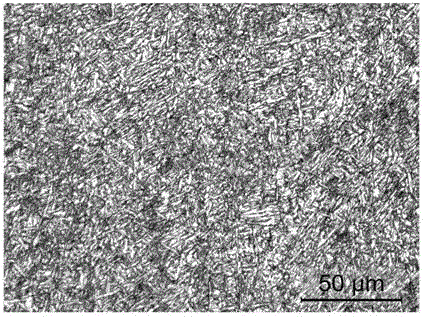

Image

Examples

Embodiment Construction

[0053] The ultra-high-strength gas-shielded welding wire and its manufacturing method according to the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. However, such explanations and illustrations do not constitute improper limitations on the technical solution of the present invention.

[0054] Table 1 lists the mass percentage distribution of each chemical element in the welding wire in Examples 1-5.

[0055] Table 1. (wt.%, the balance is Fe and other unavoidable impurities except P, S, Al, O, N and H elements)

[0056]

[0057] The welding wire in Examples 1-5 of this case is obtained by the following steps: smelting in an induction furnace, refining, continuous casting into a bloom, hot rolling, slow cooling, spinning into a wire rod, pickling, rough drawing, rough drawing When it is drawn to Ф2.2mm-Ф3.5mm, heat treatment is carried out, fine drawing and copper plating are carried out, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com