Rhenium crucible, preparation method thereof and mould for preparing rhenium crucible

A crucible and mold technology, applied in the field of rare metal materials, can solve the problems of low utilization rate of metal powder, high requirements for auxiliary equipment, large cold working hardening rate, etc., to achieve convenient installation and demoulding, good molding effect, and reduce processing. effect of margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention provides a method for preparing a rhenium crucible, which includes the following steps:

[0019] Mixing step: Mix rhenium powder and binder uniformly to make feed.

[0020] Further, in a preferred embodiment of the present invention, the binder is prepared by mixing wax, high molecular polymer, surfactant and plasticizer at 150-170°C for 1 to 3 hours. The mixing temperature is 5~25℃ higher than the melting temperature of the system, and mixing and stirring until the binder is in the form of a slurry and the color is uniform.

[0021] Specifically, in terms of parts by mass, the binder includes 60 to 75 parts of wax, 20 to 30 parts of high molecular polymer, 0.5 to 1.5 parts of surfactant, and 1 to 5 parts of plasticizer.

[0022] Further, in a preferred embodiment of the present invention, the wax is any one of paraffin wax, ozokerite wax and beeswax after slicing. The melting temperature of wax is low and the viscosity decreases rapidly with the increase...

Embodiment 1

[0045] This embodiment provides a method for preparing a rhenium crucible, including the following steps:

[0046] Mixing steps:

[0047] In parts by weight, 60 parts of paraffin wax, 25 parts of high-density polyethylene, 1 part of oleic acid and 5 parts of dioctyl phthalate are selected and added to the vacuum mixer and mixed at 170°C for 3 hours until The obtained binder is paste-like with uniform color. Then, 91 parts by weight of rhenium powder was added to the binder, and the mixing was continued for 4 hours. After the mixing, the mixture was cooled to room temperature to obtain the required feed.

[0048] Injection molding steps:

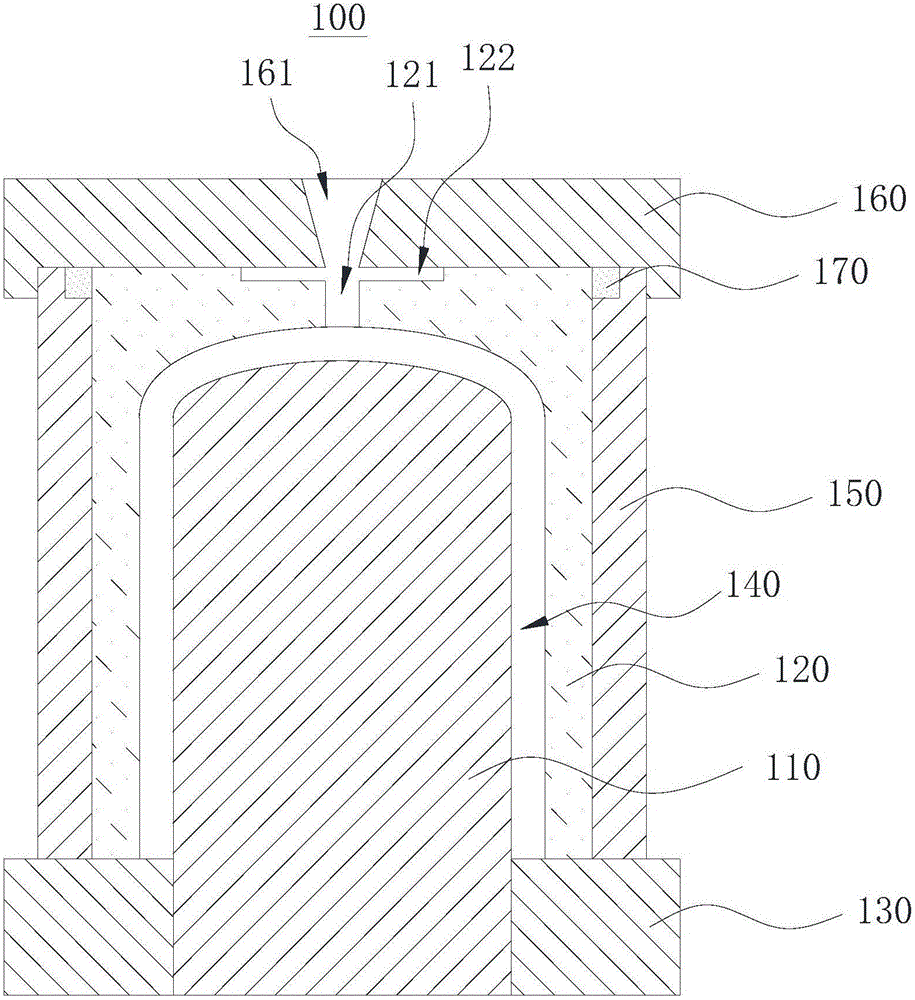

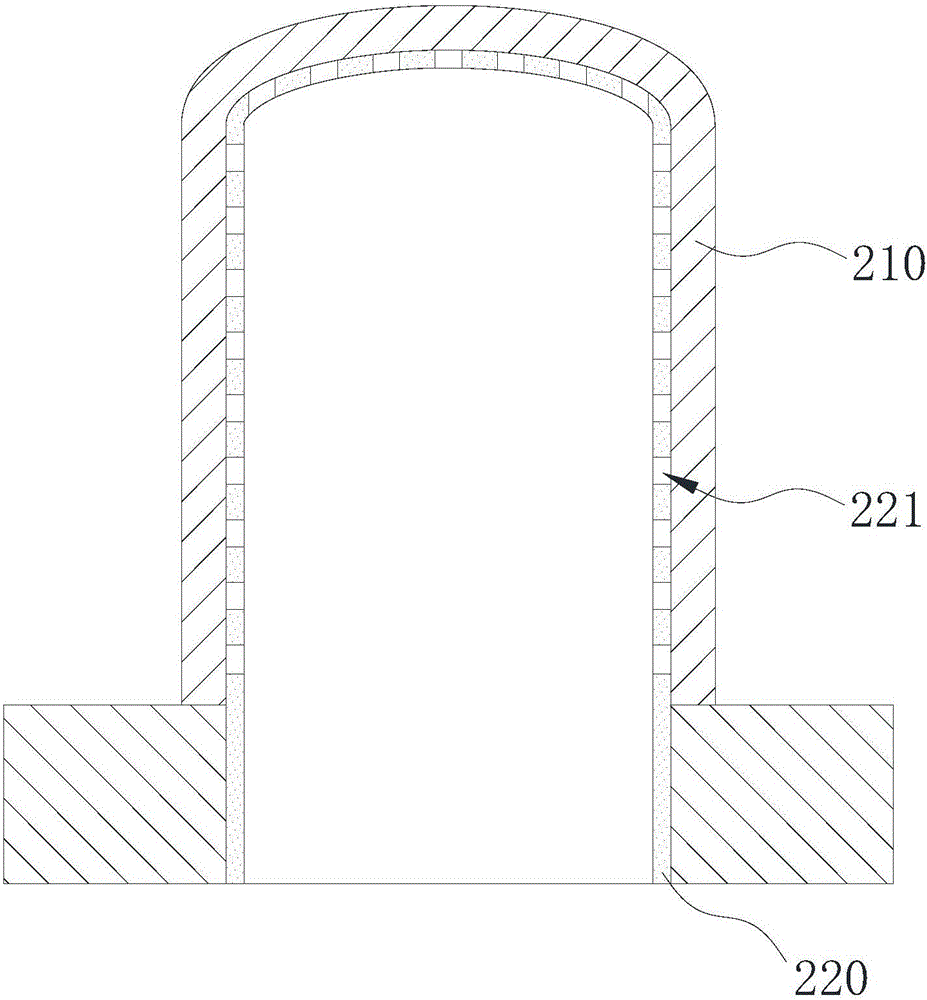

[0049] Use a vertical injection machine to inject the above feed into the mold 100 at 150°C, such as figure 1 As shown, the mold 100 includes a core mold 110 and a female mold 120. The base 130 is sleeved on the bottom of the core mold 110. The core mold 110, the female mold 120 and the base 130 together form a cavity 140 that is consistent with the...

Embodiment 2

[0057] This embodiment provides a method for preparing a rhenium crucible, including the following steps:

[0058] Mixing steps:

[0059] In parts by weight, 67 parts of ozokerite wax, 20 parts of ethylene-vinyl acetate copolymer, 1.5 parts of oleic acid and 3 parts of dibutyl phthalate are selected and added to the vacuum mixer and mixed at 150°C 1h, until the obtained binder becomes paste and the color is uniform. Then, 75 parts by weight of rhenium powder is added to the binder, and the mixing is continued for 2 hours. After the mixing is completed, it is cooled to room temperature to obtain the required feed.

[0060] Injection molding steps:

[0061] A vertical injection machine is used to inject the above-mentioned feed into a specific mold 100 at 140°C. After the mold is cooled to room temperature, the desired injection blank can be obtained by demolding.

[0062] Degreasing steps:

[0063] A thin-walled molybdenum part with multi-mesh holes is inserted into the injection blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com