Anti-wear flux-cored wire, as well as preparation method and application thereof

A technology of flux-cored welding wire and flux core, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of low coating hardness, unsatisfactory coating, and increased cost of flux-cored welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

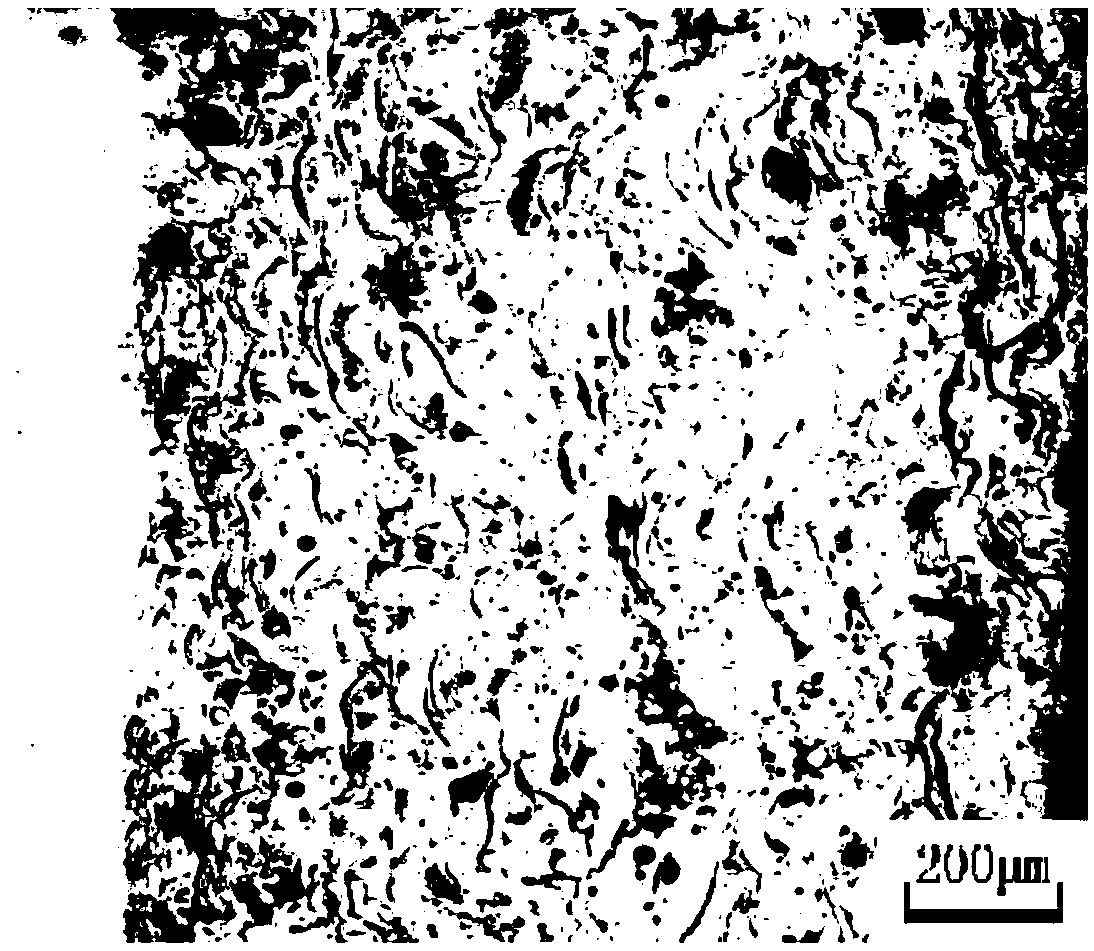

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method for the wear-resistant flux-cored welding wire described in the above technical solution, comprising the following steps:

[0038] (1) mixing the core raw materials of the wear-resistant flux-cored wire to obtain core powder;

[0039] (2) encapsulating the core powder obtained in the step (1) by using the sheath raw material to obtain a semi-finished product of wear-resistant flux-cored welding wire;

[0040] (3) Drawing the semi-finished wear-resistant flux-cored welding wire obtained in the step (2) to obtain a wear-resistant flux-cored welding wire.

[0041] The invention mixes the core raw materials of the wear-resistant flux-cored wire to obtain the core powder. In the present invention, the raw material of the flux core of the wear-resistant flux-cored wire is the same as the raw material for preparing the flux core described in the above technical solution, and will not be repeated here.

[0042] In the p...

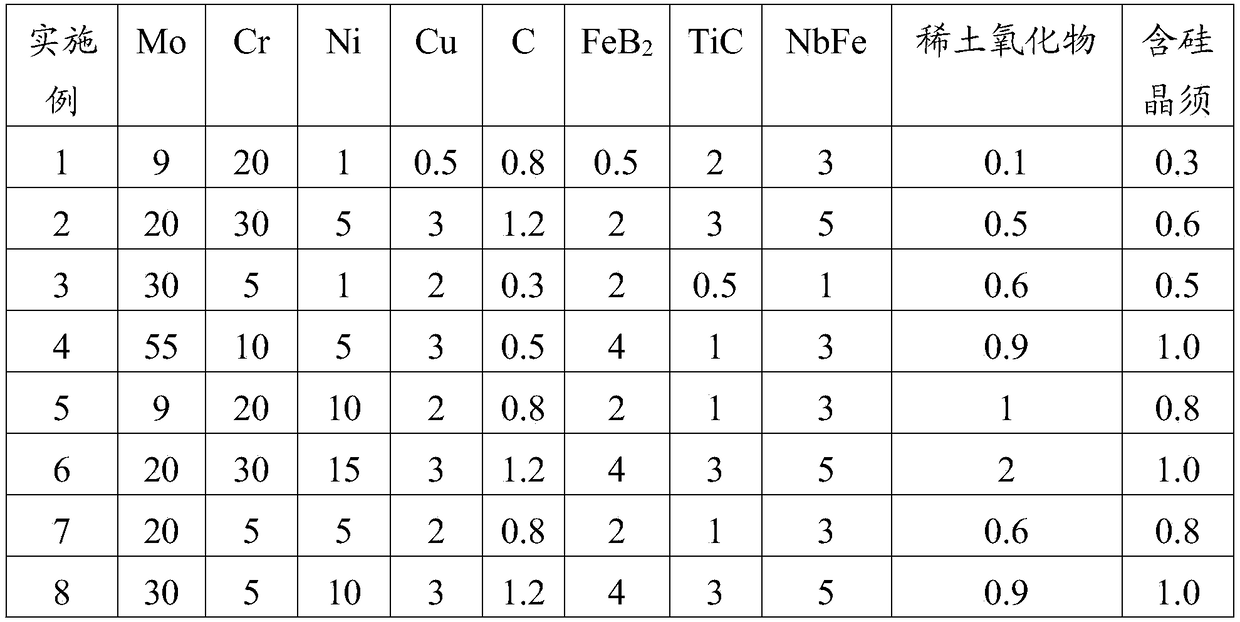

Embodiment 1

[0050] Chemical composition of drug core: 9wt% molybdenum powder, 20wt% chromium powder, 1wt% nickel powder, 0.5wt% copper powder, 0.8wt% carbon powder, 0.5wt% boron-iron alloy powder, 2wt% titanium carbide powder, 3wt% niobium Iron alloy powder, 0.1wt% lanthanum oxide, 0.3wt% Si 3 N 4 Whiskers, the balance is iron powder. Among them, the particle size of lanthanum oxide is 3 μm; Si 3 N 4 The diameter of the whiskers is 0.2 μm; the particle size of the rest of the raw materials is 65 μm.

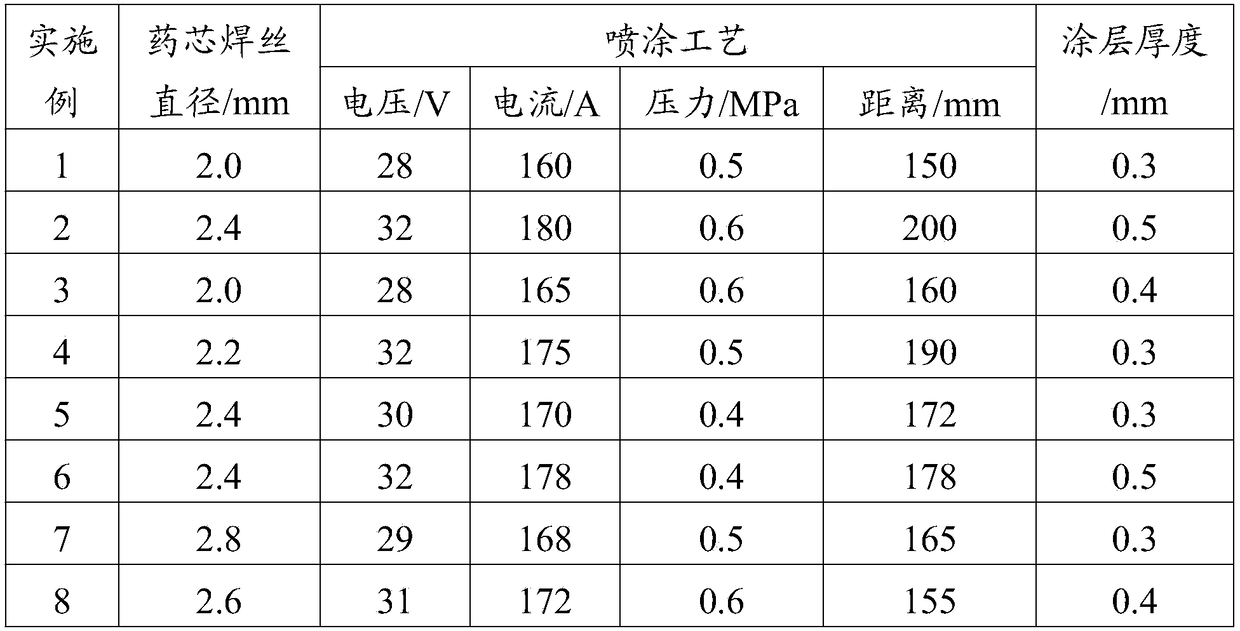

[0051] First dry the flux core naturally at 200°C and mix it; then package it with an ordinary low-carbon steel strip with a width of 14mm and a thickness of 0.5mm, the filling rate is 40%, and a semi-finished wear-resistant flux-cored wire with a diameter of 4.2mm is obtained; grading Draw to a diameter of 2.0 mm to obtain (Mo-Cr-Ni-Cu series) flux-cored welding wire.

[0052] Using Q235 steel as the base material, the surface of the base material is treated by sand blasting process to...

Embodiment 2

[0055] Prepare flux-cored welding wire and coating according to the method of Example 1, the difference is that the rare earth oxide is yttrium oxide with a particle size of 1 μm; the silicon-containing whiskers are SiC with a diameter of 0.2 μm; 70 μm; the thickness of the stainless steel strip is 0.3mm, the width is 15mm, and the filling rate of the drug core is 42%; the dosage and process parameters of the remaining components are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com