Ultrahigh-plasticity magnesium alloy and preparation method of deformation material of ultrahigh-plasticity magnesium alloy

A magnesium alloy and plasticity technology, which is applied in the field of preparation of ultra-high plasticity magnesium alloy and its deformed material, can solve the problems of difficult to realize large-scale industrial application, high dependence on equipment, complicated process, etc., and achieve the elimination of heat treatment process and simple process , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

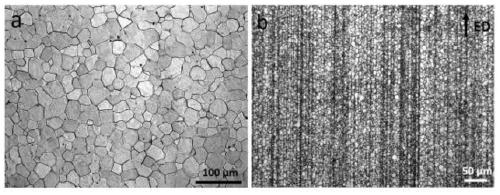

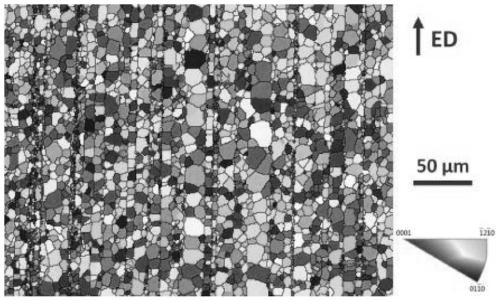

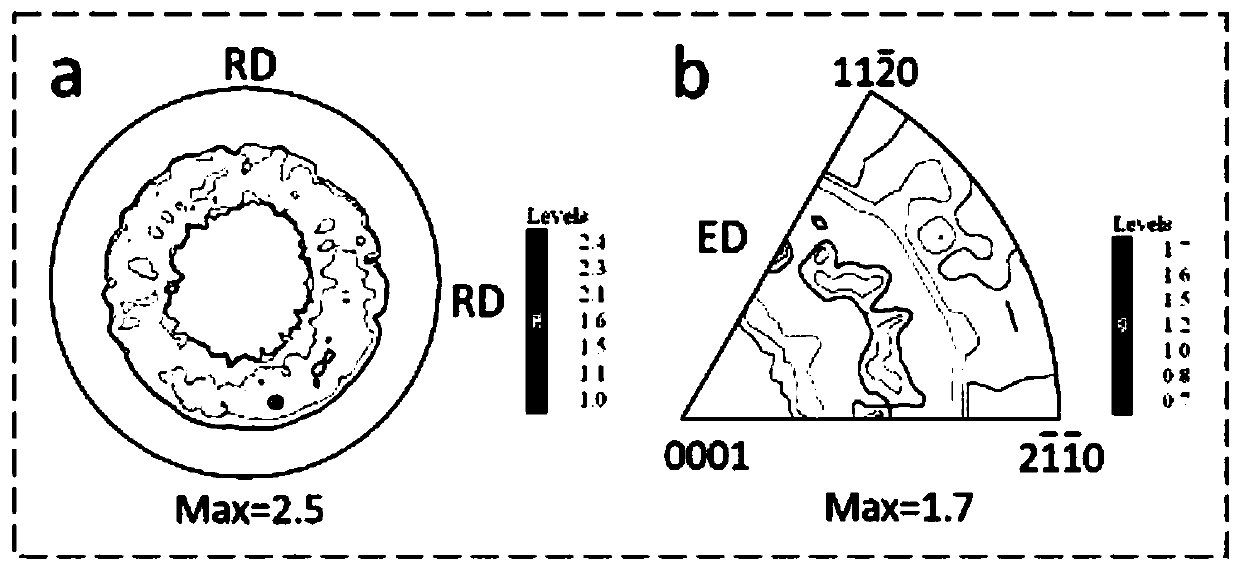

Embodiment 1

[0026] 1) The smelting of alloy: with pure magnesium ingot, Mg-Gd master alloy and Mg-Zr master alloy as raw material, carry out batching according to Gd1.0%, Zr 0.6%, balance is the weight percent of Mg, alloy batching is preheated to 50℃, sprinkle with covering agent, then heat up to 760℃, in SF 6 and CO 2 Melting is carried out under the protection of mixed gas, fully stirred after melting, left to stand, and cooled to 720°C for casting.

[0027] 2) Machining: the alloy ingot is turned into a cylindrical extrusion billet with a diameter of 80 mm and a length of 100 mm.

[0028] 3) Extrusion forming: Preheat the extrusion billet and mold at 400°C for 1 hour before extrusion, and then press the extrusion temperature at 400°C, extrusion ratio at 45, and extrusion speed at 20m / min. Just take shape.

[0029] The mechanical properties of the magnesium alloy deformed material prepared in this example are specifically as follows: the tensile yield strength at room temperature is...

Embodiment 2

[0031] 1) The smelting of alloy: with pure magnesium ingot, Mg-Gd master alloy and Mg-Zr master alloy as raw material, carry out batching according to Gd2.0%, Zr 0.6%, balance is the weight percentage of Mg, alloy batching is preheated to 50℃, sprinkle with covering agent, then heat up to 760℃, in SF 6 and CO 2 Melting is carried out under the protection of mixed gas, fully stirred after melting, left to stand, and cooled to 720°C for casting.

[0032] 2) Machining: the alloy ingot is turned into a cylindrical extrusion billet with a diameter of 80 mm and a length of 100 mm.

[0033] 3) Extrusion forming: Preheat the extrusion billet and mold at 400°C for 1 hour before extrusion, and then press the extrusion temperature at 400°C, extrusion ratio at 45, and extrusion speed at 20m / min. Just take shape.

[0034] The mechanical properties of the magnesium alloy deformed material prepared in this example are specifically as follows: the tensile yield strength at room temperature...

Embodiment 3

[0039] 1) The smelting of alloy: with pure magnesium ingot, Mg-Gd master alloy and Mg-Zr master alloy as raw material, carry out batching according to Gd3.0%, Zr 0.6%, balance is the weight percentage of Mg, alloy batching is preheated to 50℃, sprinkle with covering agent, then heat up to 760℃, in SF 6 and CO 2 Melting is carried out under the protection of mixed gas, fully stirred after melting, left to stand, and cooled to 720°C for casting.

[0040] 2) Machining: the alloy ingot is turned into a cylindrical extrusion billet with a diameter of 80 mm and a length of 100 mm.

[0041]3) Extrusion forming: Preheat the extrusion billet and mold at 400°C for 1 hour before extrusion, and then press the extrusion temperature at 400°C, extrusion ratio at 45, and extrusion speed at 20m / min. Just take shape.

[0042] The mechanical properties of the magnesium alloy deformed material prepared in this example are specifically as follows: the tensile yield strength at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com