High-bending-resistance, high-strength and high-toughness die steel and manufacturing method thereof

A manufacturing method and die steel technology, applied in the field of cold stamping die materials, can solve the problems of unsatisfactory bending resistance and anti-fracture ability, and achieve the effects of low alloying element content, refined microstructure and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

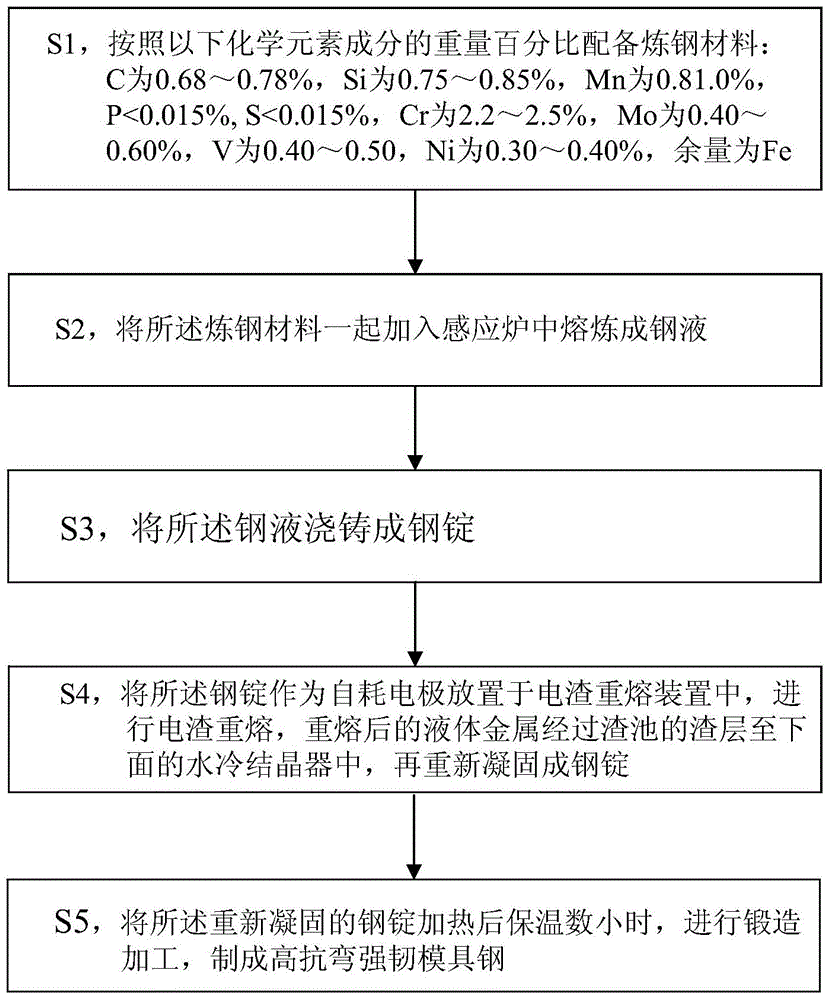

Method used

Image

Examples

Embodiment 1

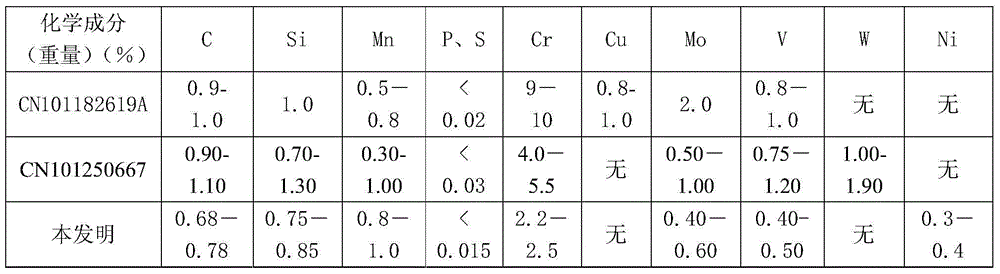

[0076] In this example, the composition and weight percentage of the cold work die steel are as follows:

[0077] C0.73%, Si0.79%, Mn0.83%, Cr2.30%, Mo0.55%,

[0078] V0.46%, Ni0.33%, P0.013%, S0.010%, Fe balance.

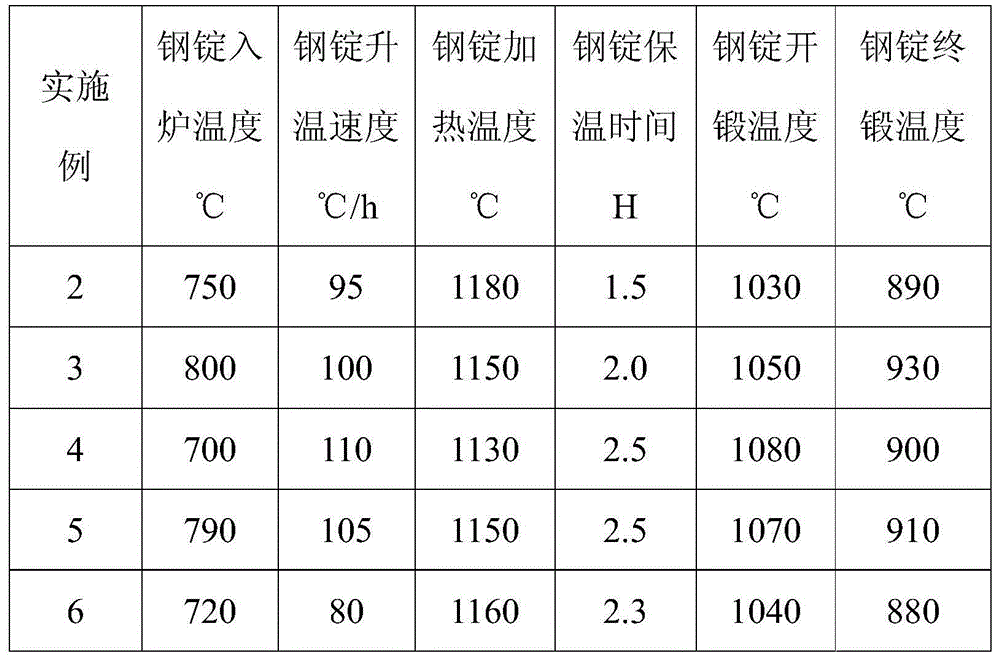

[0079] The ratio of the chemical composition of the high bending strength and toughness mold steel in this embodiment is melted in the induction furnace, and the steel ingot cast into it is placed in the electroslag remelting device as a consumable electrode, and the electroslag remelting is carried out, and the liquid metal The slag layer passing through the slag pool falls into the water-cooled crystallizer below, and then re-solidifies into steel ingots. When the above-mentioned solidified steel ingots enter the heating furnace of the radial forging machine, the temperature is controlled at 790°C, and the heating rate is controlled at 90°C / h. Heating to 1150°C and keeping it warm for 1.5 hours, then forging to become a high flexural toughness die steel. The ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com