Ultrahigh-strength gas protection welding wire containing V and manufacturing method thereof

一种气体保护焊丝、超高强的技术,应用在制造工具、焊接介质、焊接设备等方向,能够解决低温冲击韧性降低、焊接材料成本提高等问题,达到相变温度降低、生产成本低、细化奥氏体晶粒的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

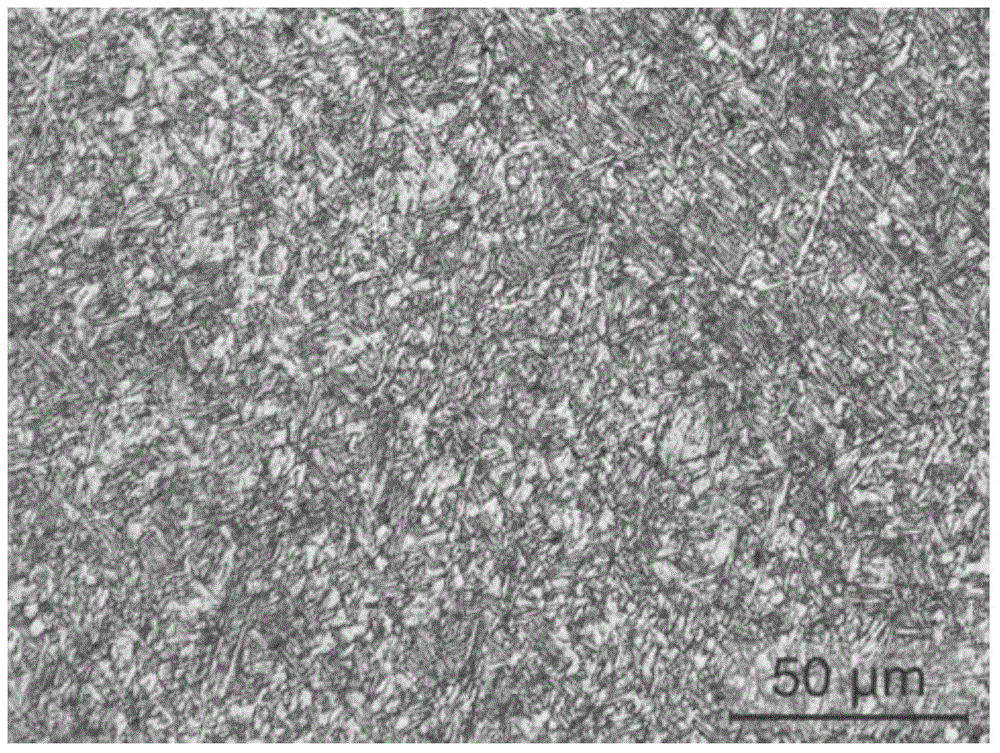

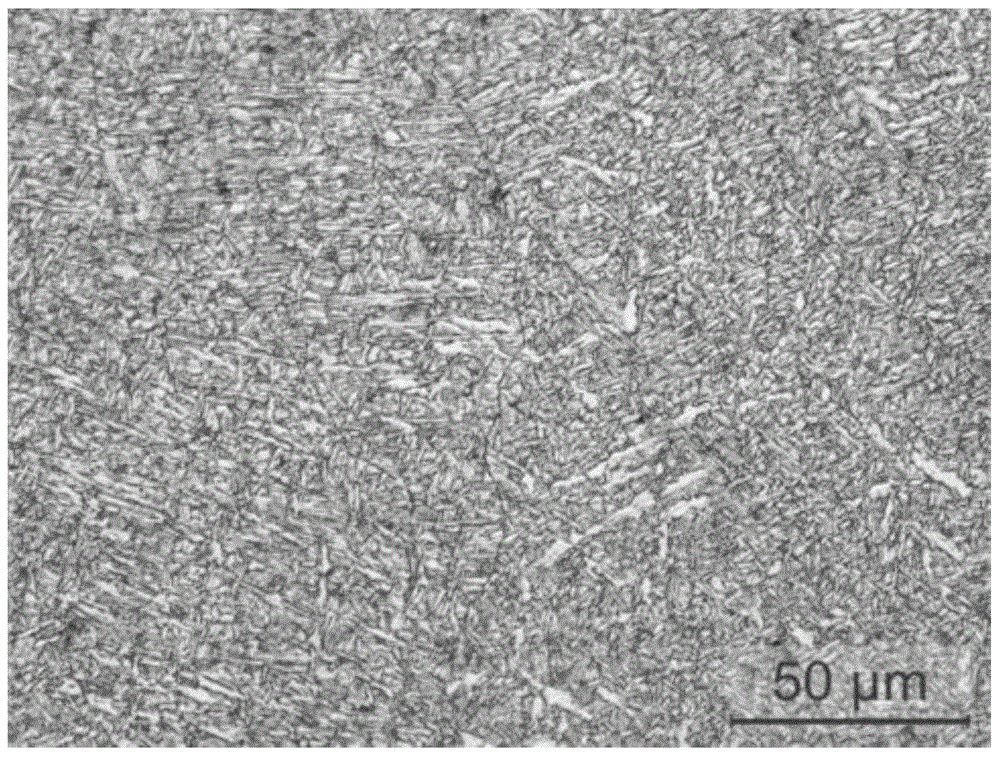

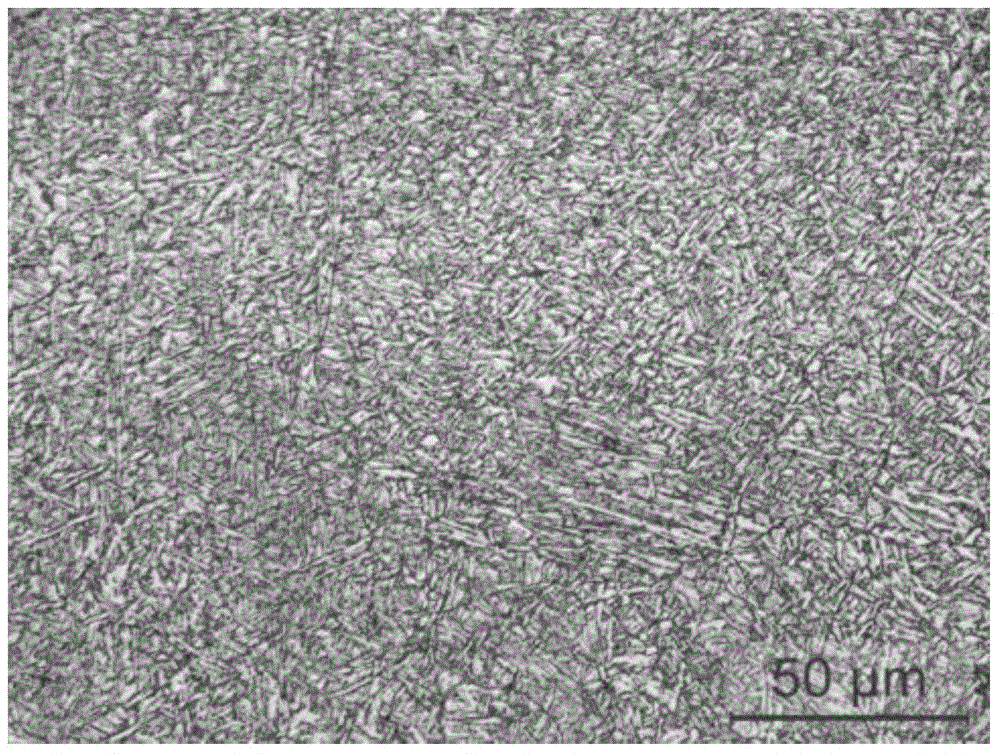

[0047] The V-containing ultra-high-strength gas-shielded welding wire and its manufacturing method described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific examples. However, such explanations and illustrations do not constitute improper limitations on the technical solution of the present invention. .

[0048] Table 1 shows the mass percentage ratio of the chemical components of the welding wire in Examples 1-5 of this case.

[0049] Table 1. (wt.%, the balance is Fe and other unavoidable impurities except P, S, Al, O and H elements)

[0050] serial number

C

Si

mn

Cu

Cr

Mo

Ni

Ti

V

N

1

0.085

0.78

1.90

0.06

0.36

0.49

1.66

0.16

0.02

0.008

2

0.105

0.70

1.85

0.13

0.28

0.42

1.38

0.11

0.04

0.011

3

0.093

0.75

1.85

0.16

0.23

0.60

1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com