Preparation method of antibacterial corrosion-resistant stainless steel

A stainless steel and alloy technology, applied in the direction of manufacturing tools, heat treatment equipment, quenching agent, etc., can solve the problem of weak corrosion resistance of antibacterial stainless steel, to achieve the effect of increasing the use value and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

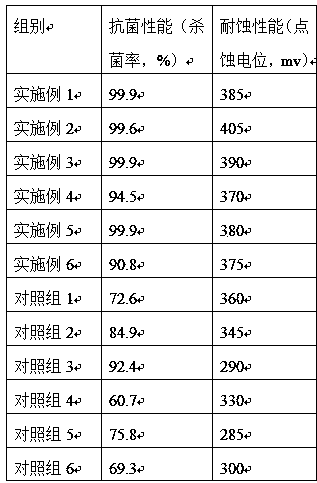

Examples

preparation example Construction

[0019] A preparation method for antibacterial and corrosion-resistant stainless steel, comprising the following steps:

[0020] (1) Preparation of alloy materials: Mix copper ingots and holmium ingots at a weight ratio of 68-72:5, place them in a heating furnace, pass argon gas into the heating furnace, heat to melt to obtain a melt, and stir for 3-5 minutes Finally, keep warm for 40-60 minutes, then let it stand for 5-10 minutes, inject it into the mold, and obtain the alloy material;

[0021] (2) Melting the 304-type stainless steel raw material sample and the alloy material obtained in step (1) in a vacuum induction furnace at a weight ratio of 95-97:5 to obtain an ingot;

[0022] (3) After the ingot is forged, hot rolling is carried out several times, and the final rolling temperature is selected as 905-915°C, and then the obtained plate is put into a bell furnace filled with a protective atmosphere, and the temperature is 780-820°C Keep it warm for 3-4 hours, and then co...

Embodiment 1

[0038] A preparation method for antibacterial and corrosion-resistant stainless steel, comprising the following steps:

[0039] (1) Preparation of alloy materials: Mix copper ingots and holmium ingots at a weight ratio of 70:5, place them in a heating furnace, pass argon gas into the heating furnace, and heat to 1100°C to melt to obtain a melt. After stirring for 4 minutes, Insulate for 50 minutes, then let it stand for 8 minutes, pour it into the mold, and obtain the alloy material;

[0040] (2) Melting the 304-type stainless steel raw material sample and the alloy material obtained in step (1) in a vacuum induction furnace at a weight ratio of 96:5 at a melting temperature of 1420-1460°C to obtain an ingot;

[0041] The chemical composition of the 304 type stainless steel raw material sample is by weight: C0.02%, Mn1.16%, P0.04%, S0.5%, Cr19.5%, Ni10%, and the balance is iron;

[0042] (3) After the ingot is forged, hot rolling is carried out several times. The final rollin...

Embodiment 2

[0045] A preparation method for antibacterial and corrosion-resistant stainless steel, comprising the following steps:

[0046] (1) Preparation of alloy materials: Mix copper ingots and holmium ingots at a weight ratio of 72:5, place them in a heating furnace, pass argon gas into the heating furnace, heat to 1110°C to melt to obtain a melt, and stir for 3 minutes. Insulate for 60 minutes, then let it stand for 5 minutes, inject it into the mold, and obtain the alloy material;

[0047] (2) The 304-type stainless steel raw material sample and the alloy material obtained in step (1) were melted in a vacuum induction furnace at a weight ratio of 95:5, and the melting temperature was 1460°C to obtain an ingot;

[0048] The chemical composition of the 304 type stainless steel raw material sample is by weight: C0.02%, Mn1.16%, P0.04%, S0.5%, Cr19.5%, Ni10%, and the balance is iron;

[0049] (3) After the ingot is forged, hot rolling is carried out several times. The final rolling temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com