Steel for high-hardness shield cutter and manufacturing method thereof

A shield cutting tool and manufacturing method technology, applied in the field of alloy steel manufacturing process, can solve the problems of complex process, unenvironmental protection, long process, etc., and achieve the effects of increasing fatigue resistance, improving hardness and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Smelting, casting and forging were carried out according to the above composition range, and then the composition of the forged billet was tested, and the composition is shown in Table 1.

[0036] Table 1 Composition of Forging Billets (wt.%)

[0037]

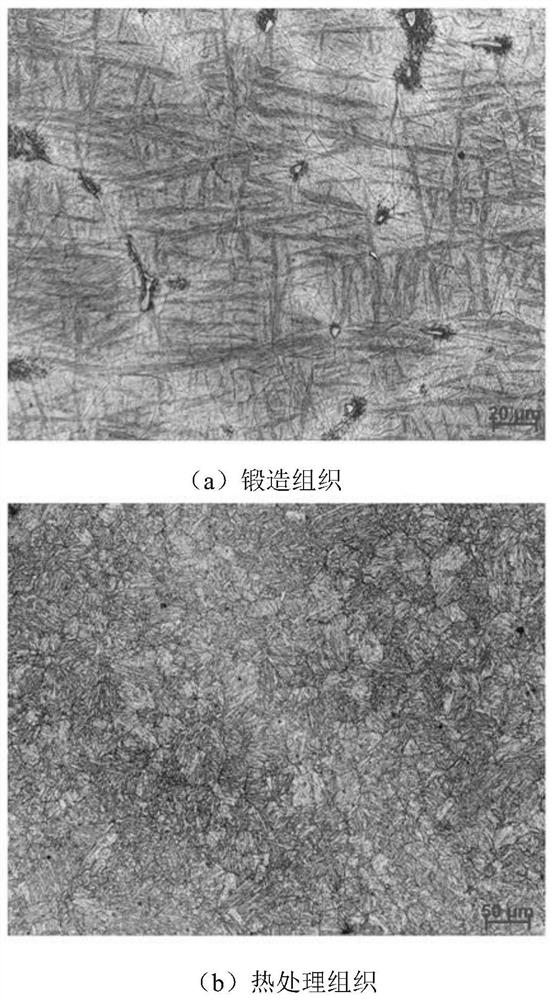

[0038] The forging adopts the following process: the preheating temperature of the forging anvil is 200-250°C, and the ingot is subjected to multi-directional forging in the temperature range of 1100-1200°C; the final forging temperature is ≥900°C, and the tissue type is iron ferrite and pearlite, such as figure 1 (a). Heat treatment: heat the test steel to 1050°C for 30 minutes, then quench it in a salt bath to 200°C, put it in a resistance furnace at 350°C for 30 minutes, and cool it in air. At this time, the structure type is martensite + retained austenite figure 1 (b).

[0039] Table 2 Mechanical properties of shield steel

[0040]

Embodiment 2

[0041]Embodiment 2: Carry out smelting, casting and forging according to the above composition range, and then detect the composition of the forged billet, and the composition 2 is shown in Table 3.

[0042] Table 3 Composition of Forging Billets (wt.%)

[0043]

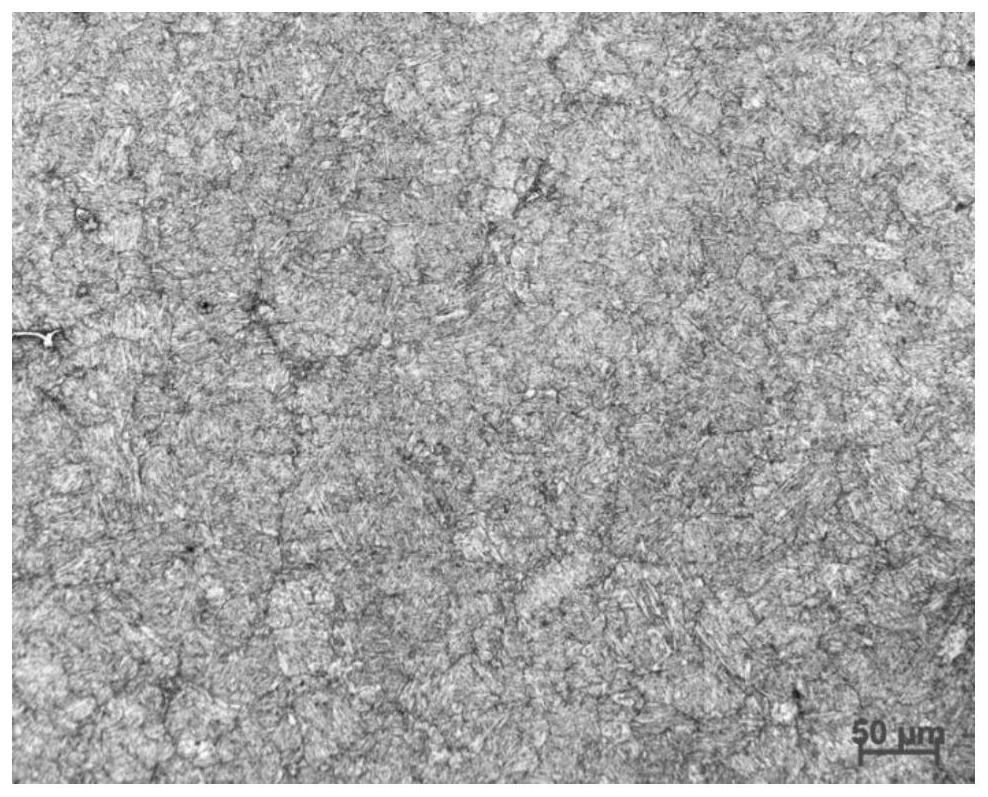

[0044] The manufacture method of steel is the same as embodiment 1, and heat treatment organization is as figure 2 .

[0045] Table 4 Mechanical properties of shield steel

[0046]

Embodiment 3

[0047] Embodiment 3: The steel composition of this embodiment is the same as that of Embodiment 1. Steel is manufactured as follows:

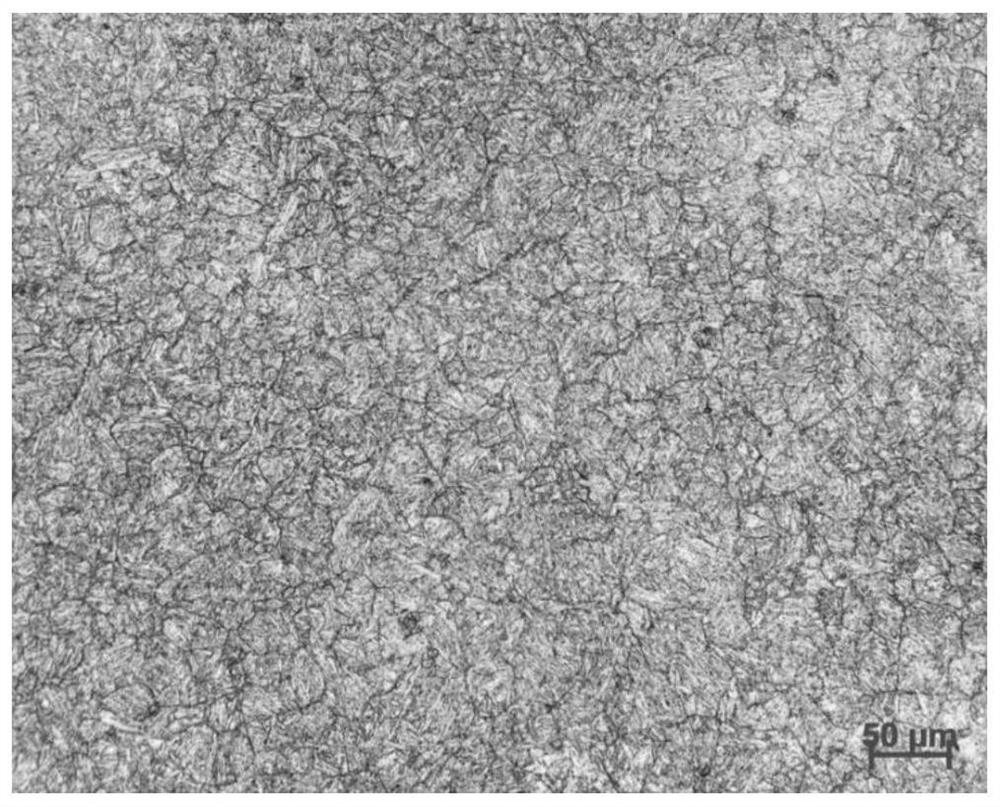

[0048] The forging adopts the following process: the preheating temperature of the forging anvil is 200-250°C, and the ingot is subjected to multi-directional forging in the temperature range of 1100-1200°C; the final forging temperature is ≥900°C. Heat treatment: heat the test steel to 1050°C for 30 minutes, then quench it in a salt bath to 150°C, then put it in a resistance furnace at 350°C and hold it for 30 minutes, then air cool it out of the furnace. At this time, the structure type is martensite + retained austenite. organized as image 3 .

[0049] Table 5 Mechanical properties of shield steel

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com