500E Australian standard wire and production method thereof

A production method and wire technology, applied in the field of materials, can solve problems such as low strength, reduced vanadium, and different performance stability, and achieve the effects of increasing yield strength, increasing strength, and increasing dislocation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

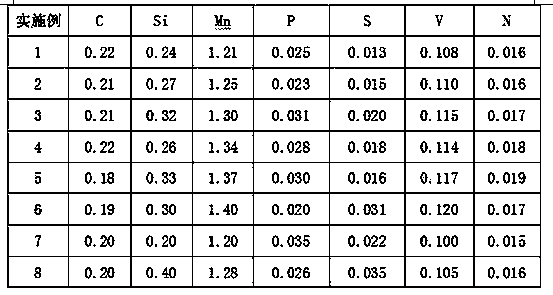

Examples

Embodiment 1

[0017] Example 1: The 500E Australian standard wire rod is prepared by the following specific process.

[0018] Put the billet into a heating furnace with a temperature of 1100-1180°C in the soaking section and heat it. The holding time in the soaking section is 50 minutes, so that the billet reaches a heating temperature of 1100°C and is released from the furnace; the heated billet is descaled by high-pressure water Afterwards, carry out rough, intermediate and pre-finish rolling. The starting temperature of rough rolling is 1050°C; the rolled piece is cooled to 910°C by passing through water, and then finish rolling is started. Spinning: After spinning, the method of weak cooling at the front end and air cooling at the rear end is adopted. The cooling speed in the weak cooling zone is controlled at 4°C / s, and the coiling temperature is controlled at 540°C for coiling. After coiling, air cooling is used to obtain uniform performance indicators. 500E Australian standard wire, ...

Embodiment 2

[0019] Embodiment 2: This 500E Australian standard wire rod is prepared by the following specific process.

[0020] Put the billet into a heating furnace with a temperature of 1100-1180°C in the soaking section and heat it. The holding time in the soaking section is 55 minutes, so that the billet reaches a heating temperature of 1120°C and is released from the furnace; the heated billet is descaled by high-pressure water Afterwards, carry out rough, intermediate and pre-finish rolling. The starting temperature of rough rolling is 1065°C; the rolled piece is cooled to 915°C by passing through water, and then finish rolling is started. Spinning: After spinning, the method of weak cooling at the front end and air cooling at the rear end is adopted. The cooling speed in the weak cooling zone is controlled at 5°C / s, the coil collection temperature is controlled at 525°C for coil collection, and the coil is air-cooled after collection to obtain uniform performance indicators 500E Au...

Embodiment 3

[0021] Embodiment 3: The 500E Australian standard wire rod is prepared by the following specific process.

[0022] Put the billet into a heating furnace with a temperature of 1100-1180°C in the soaking section and heat it. The holding time in the soaking section is 45 minutes, so that the billet reaches the heating temperature of 1110°C and is released from the furnace; the heated billet is descaled by high-pressure water Afterwards, carry out rough, medium and pre-finish rolling. The starting temperature of rough rolling is 1055°C; the rolled piece is cooled to 930°C by passing water, and then finish rolling is started. The finishing temperature is controlled to be 1010°C; the temperature is cooled to 910°C by passing water Spinning: After spinning, adopt weak cooling at the front end and air cooling at the rear end. The cooling speed in the weak cooling zone is controlled at 4.5°C / s, and the coil collection temperature is controlled at 535°C for coil collection. After the coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com