Hot rolled wire rod for 600 MPa-grade high-strength welding and production method for hot rolled wire rod

A technology of hot-rolled wire rods and production methods, applied in the field of hot-rolled wire rods, can solve problems such as high requirements for steel rolling equipment, increased process costs, and complicated steel rolling processes, and achieve the goals of increasing dislocation resistance, low production costs, and improving strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

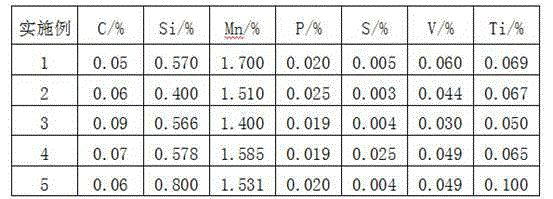

[0016] Embodiment 1-5: The 600MPa grade high-strength welding hot-rolled wire rod adopts the following billet composition and production method.

[0017] 1. The steel billets used in this 600MPa grade high-strength welding wire rod are smelted by vanadium-titanium alloying method, and its chemical composition is shown in Table 1.

[0018] Table 1: Billet composition (wt) used in each embodiment

[0019]

[0020] Note: The rest is Fe and unavoidable impurities.

[0021] 2. The production method and product performance of the 600MPa-grade hot-rolled wire rod for high-strength welding are as follows.

Embodiment 1

[0022] Embodiment 1: Put the billet corresponding to the embodiment in Table 1 into a heating furnace with a furnace temperature of 1100-1180° C. in the soaking section for heating, and the soaking time in the soaking section is 50 minutes to make the billet reach a heating temperature of 1145° C. , out of the furnace; the heated billet is descaled by high-pressure water and then rough-rolled. The rough-rolling start temperature is 1050°C; Water cooling to 865°C for silk spinning; after spinning, slow cooling is adopted, the cooling speed is 0.85°C / s, the coiling temperature is 550°C, and the coiling is air-cooled to obtain a 600MPa grade high-strength welding hot rolling with uniform performance. Wire rod; the tensile strength is 610MPa, and the reduction of area is 75.5%.

Embodiment 2

[0023] Embodiment 2: put the billet corresponding to the embodiment in Table 1 into a heating furnace with a furnace temperature of 1100-1180° C. in the soaking section for heating, and the soaking time in the soaking section is 55 minutes to make the billet reach a heating temperature of 1120° C. , out of the furnace; the heated billet was descaled by high-pressure water and then rough rolled. The starting temperature of rough rolling was 1065°C; Water cooling to 870°C for silk spinning; after spinning, slow cooling is adopted, the cooling rate is 0.86°C / s, the coiling temperature is 500°C, and the coiling is air-cooled to obtain a 600MPa-level high-strength welding hot rolling with uniform performance. Wire rod; the tensile strength is 620MPa, and the reduction of area is 72.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com