Nickel base powder high-temperature alloy with high tensile strength and preparation method thereof

A high-tensile strength, high-temperature alloy technology, applied in the field of powder superalloys, can solve the problem that FGH4097 alloy cannot meet the tensile strength of hot-end rotating parts such as aero-engine turbine disks, etc., to increase the grain boundary strengthening effect and simplify the heat treatment system , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The object of the present invention is to provide a nickel-based powder superalloy with high tensile strength, the chemical composition and mass percentage (wt%) of the alloy are: C 0.04-0.08, Co 17.0-19.0, Cr 11.0- 13.0, W 6.0-6.7, Mo4.3-5.0, Al 4.9-5.4, Ti 1.5-1.9, Nb 2.5-2.9, Hf 0.2-0.5, B<0.03, Zr<0.03, Mg<0.005, Ce<0.002, Yu The amount is Ni and other unavoidable impurities.

[0030] The main technical scheme of the present invention is to realize nickel-based powder superalloy by adding γ′ phase forming elements Al, Ti, Nb, solid solution strengthening elements Cr, Co, W, Mo and grain boundary strengthening elements C, B, Zr, Hf High tensile strength, while controlling the content of Cr, W, Mo to reduce the precipitation tendency of topological close-packed TCP phase, so as to obtain a composition range with good comprehensive properties. Specifically, Al, Ti, and Nb added to the alloy components can increase the content of the γ′ phase and the degree of alloying...

Embodiment 2

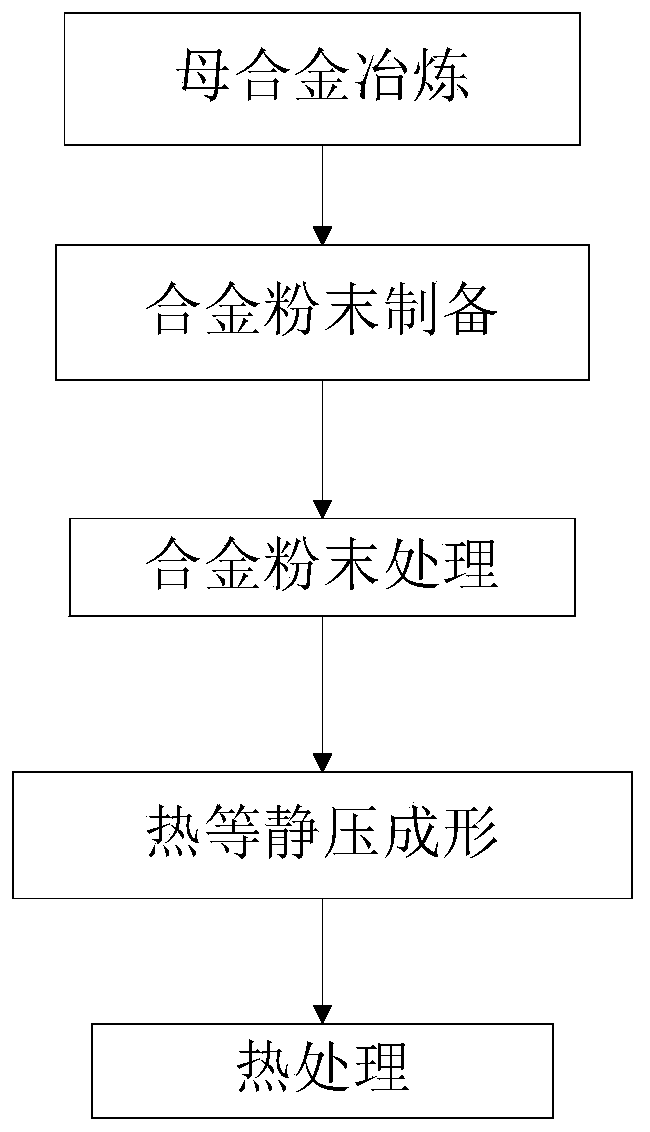

[0038] The present invention also provides a method for preparing a nickel-based powder superalloy with high tensile strength, such as figure 1 As shown, the preparation method specifically includes the following steps:

[0039] Step S1. Prepare raw materials according to the chemical composition and mass fraction of the nickel-based powder superalloy, and prepare master alloy rods by vacuum induction melting process;

[0040] Step S2. Making the master alloy bar into alloy powder; specifically, using the plasma rotating electrode method to make the master alloy bar into alloy powder, and the particle size of the alloy powder is 50 μm to 150 μm;

[0041] Step S3. The alloy powder is loaded into a low-carbon steel ladle, and vacuum degassed and sealed to obtain the alloy powder after sealing;

[0042] Step S4. Perform hot isostatic pressing on the nickel-based alloy powder after sealing and welding to obtain a cylindrical ingot;

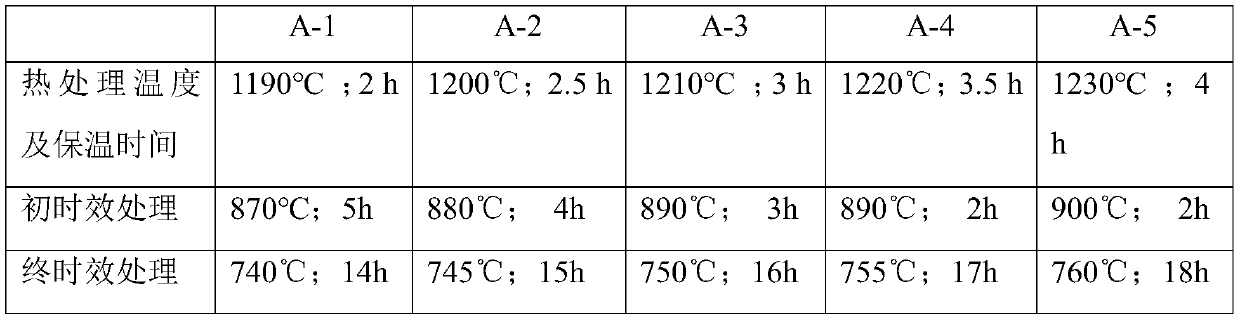

[0043] Step S5. Perform heat treatment on the...

Embodiment 3

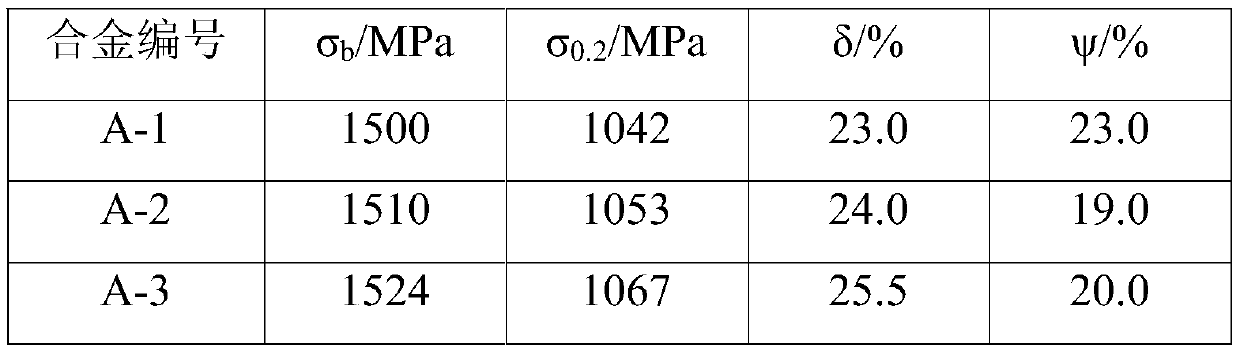

[0058] This embodiment provides five different nickel-based powder superalloys, which are:

[0059] (1) The chemical composition and mass percentage (wt%) of nickel-based powder superalloy A-1 alloy are: C 0.04, Co17.0, Cr 11.0, W 6.0, Mo 4.3, Al 5.1, Ti 1.7, Nb 2.7, Hf 0.32, Zr 0.014, B 0.015, Mg0.003, Ce 0.0012, the balance is Ni and other unavoidable impurities.

[0060] (2) The chemical composition and mass percentage (wt%) of nickel-based powder superalloy A-2 alloy are: C 0.04, Co17.0, Cr 13.0, W 6.0, Mo 4.3, Al 5.1, Ti 1.7, Nb 2.7, Hf 0.32, Zr 0.014, B 0.015, Mg0.003, Ce 0.0014, the balance is Ni and other unavoidable impurities.

[0061] (3) The chemical composition and mass percentage (wt%) of nickel-based powder superalloy A-3 alloy are: C 0.04, Co19.0, Cr 13.0, W 6.0, Mo 4.3, Al 5.1, Ti 1.7, Nb 2.7, Hf 0.32, Zr 0.014, B 0.015, Mg0.002, Ce 0.0015, the balance is Ni and other unavoidable impurities.

[0062] (4) The chemical composition and mass percentage (wt%) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com