Low-temperature-resistant corrosion-resistant H-shaped steel with yield strength of 800 MPa and preparation method thereof

A yield strength, 800mpa technology, applied in the field of low-temperature corrosion-resistant H-beam and its preparation, can solve the problem of low strength level, and achieve the effects of low production cost, stable performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Carry out smelting and casting according to the above composition range, and then detect the composition of the slab, composition 1 is shown in Table 1.

[0028] Table 1 Slab composition (wt.%)

[0029]

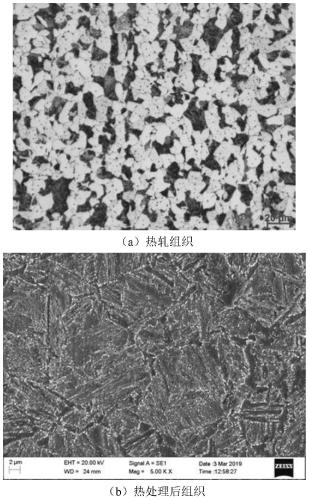

[0030] The rolling process adopts the following process: heating the cast slab from room temperature to 1210°C, holding it for 120min, starting the rough rolling at 1160°C, starting the finish rolling at 1000°C, and finishing the finish rolling at 805°C. There is no deformation at -890°C, and the compression ratio is 6.3. At this time, the structure types of hot-rolled H-beams are ferrite and pearlite, see figure 1 As shown in (a), the heat treatment process is as follows: heat the H-shaped steel to 900°C and keep it for 30 minutes, then cool it to room temperature at a cooling rate of about 80°C / s, then heat the H-shaped steel to 600°C and keep it for 30 minutes, and then take it out of the furnace and air-cool it to room temperature. At this time, the structure t...

Embodiment 2

[0034] Carry out smelting and casting according to the above composition range, and then detect the composition of the slab, composition 2 is shown in Table 3.

[0035] Table 3 Slab composition (wt.%)

[0036]

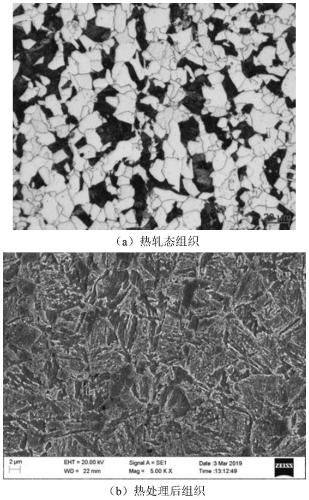

[0037] The rolling process adopts the following process: heating the cast slab from room temperature to 1210°C, holding it for 130 minutes, starting the rough rolling at 1160°C, starting the finish rolling at 1000°C, and finishing the finish rolling at 800°C. There is no deformation at -900°C, and the compression ratio is 7.2. At this time, the structure types of hot-rolled H-beams are ferrite and pearlite, see figure 2 As shown in (a), the heat treatment process is as follows: heat the H-shaped steel to 900°C and keep it for 30 minutes, then cool it to room temperature at a cooling rate of about 40°C / s, then heat the H-shaped steel to 550°C and keep it for 30 minutes, and then take it out of the furnace and air-cool it to room temperature. At this time, the struc...

Embodiment 3

[0041] Carry out smelting and casting according to the above composition range, and then detect the composition of the slab, composition 3 is shown in Table 5.

[0042] Table 5 Slab composition (wt.%)

[0043]

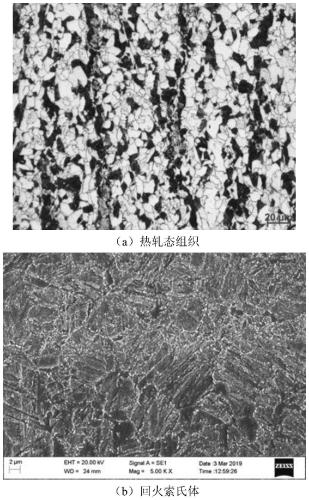

[0044] The rolling process adopts the following process: heating the cast slab from room temperature to 1210°C, holding it for 150min, starting the rough rolling at 1160°C, starting the finish rolling at 1000°C, and finishing the finish rolling at 800°C. There is no deformation at -900°C, and the compression ratio is 7.2. At this time, the structure types of hot-rolled H-beams are ferrite and pearlite, see image 3 As shown in (a), the heat treatment process is as follows: heat the H-shaped steel to 900°C for 45 minutes, then cool it to room temperature at a cooling rate of about 80°C / s, then heat the H-shaped steel to 600°C for 45 minutes, and then take it out of the furnace and air-cool it to room temperature. At this time, the structure type of H-shaped steel is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com