Precipitation-hardened stainless steel for cutting tool and manufacturing method of precipitation-hardened stainless steel

A technology of precipitation hardening and stainless steel, applied in the field of precipitation hardening stainless steel for cutting tools and its manufacturing, can solve the problems of no antibacterial effect, low martensite, limited use, etc.

Inactive Publication Date: 2018-05-01

上海落日新材料科技有限公司 +1

View PDF2 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the high content of Cr and low Ni content in this invention patent, the content of martensite formed during the quenching process is low, while the content of retained austenite is high, which makes it difficult for the steel plate after heat treatment to meet the requirements of medical equipment. The required strength and hardness, although the invention has high low temperature toughness and normal temperature elongation, but the low hardness limits its use in the medical device industry

In addition, since the invention does not contain Cu elements, it has no antibacterial effect, and its use in the medical device industry will also be limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

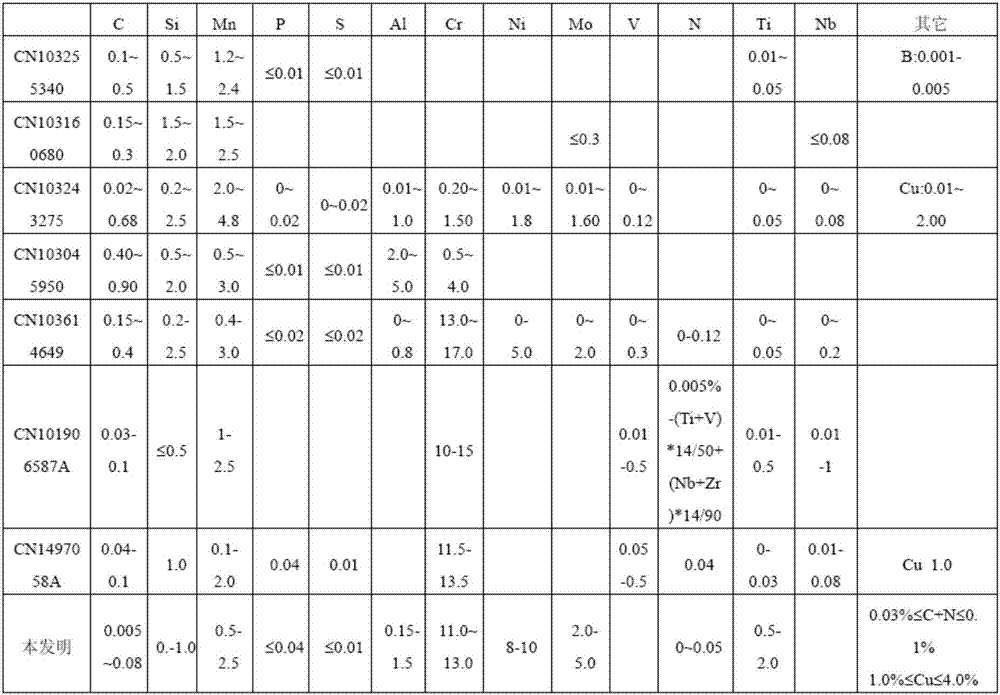

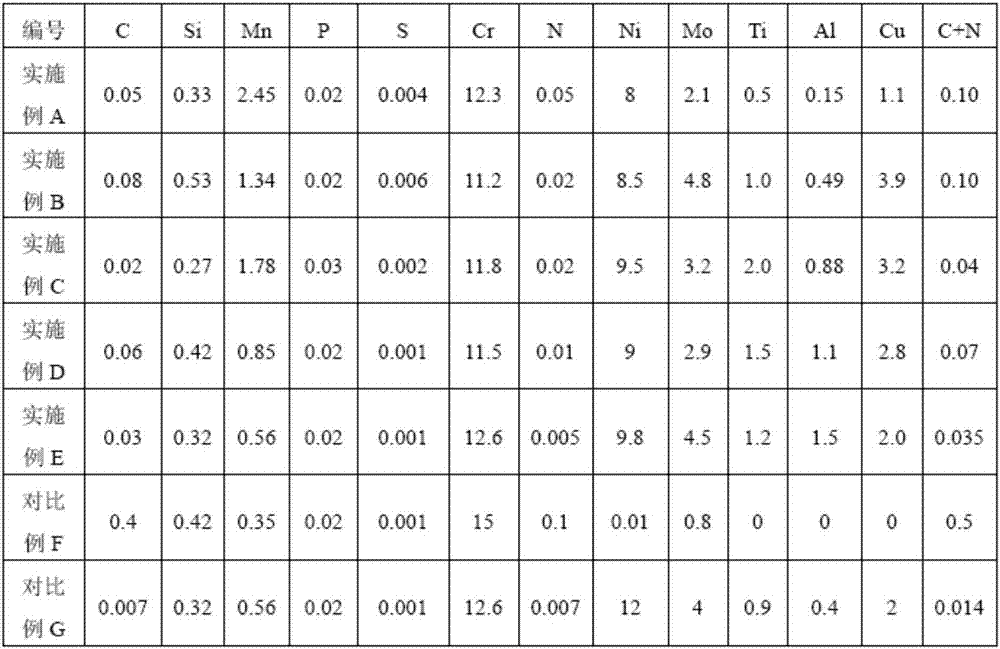

[0029] The chemical compositions of Examples A-E of the present invention are shown in Table 2, and the heat treatment process and properties of Examples A-E are shown in Table 3.

[0030] The chemical composition (wt,%) of the embodiment of table 2

[0031]

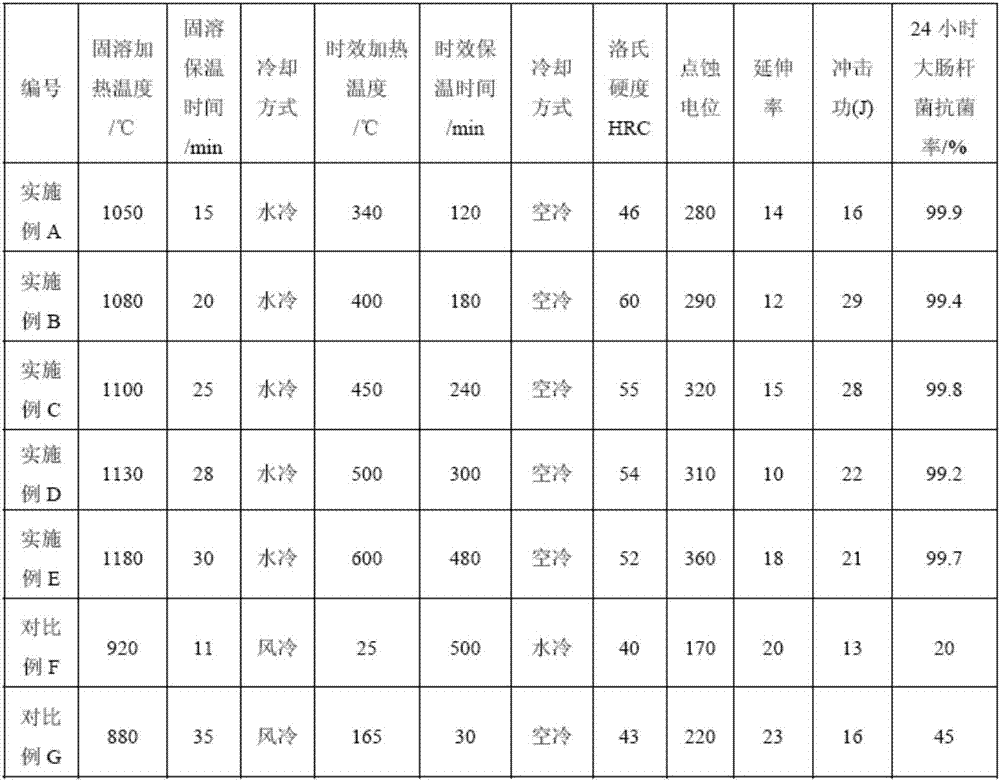

[0032] Heat treatment process and performance of the embodiment of table 3

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a precipitation-hardened stainless steel for a surgical instrument with excellent corrosion resistance and mechanical performance and a manufacturing method of the precipitation-hardened stainless steel. The indexes of the hardness, the toughness, the corrosion resistance, the mold resistance and the like of the precipitation-hardened stainless steel are all superior to martensitic stainless steel of the same kind. The precipitation-hardened stainless steel comprises the following components of, by weight, 0.005-0.08% of C, less than or equal to 0.05% of N, less than orequal to 1.0% of Si, 0.5-2.5% of Mn, less than or equal to 0.04% of P, less than or equal to 0.01% of S, 11.0-13.0% of Cr, 8.0-10.0% of Ni, greater than or equal to 0.03% and less than or equal to 0.10% of the sum of C and N, 2.0-5.0% of Mo, 1.0-4.0% of Cu, 0.5-2.0% of Ti, 0.15-1.5% of Al, less than or equal to (5*10<-4>)% of the product of Ti and N and the balance unavoidable impurities and Fe.The preparation method comprises the steps that (1) the set components are subjected to alloy smelting by adopting an electric furnace and an external refining mode, so that a steel ingot is formed; (2) the steel ingot is forged to be a steel slab after scalping is conducted, the heating temperature of the forging process is 1050-1250 DEG C, the heating time is 2-5 hours, and the finish forging temperature is 900-980 DEG C; (3) the steel slab is subjected to hot rolling by using a hot rolling machine, so that a hot rolled steel plate or steel belt is prepared, the hot rolling heating temperature is 1000-1200 DEG C, the heat preservation time is 2-5 hours, and the finish rolling temperature is 850-930 DEG C; (4) high-temperature solution treatment is conducted on the steel plate by adoptingsolid solution annealing furnace equipment, the solid solution temperature is 1000-1200 DEG C, the solid solution heat preservation time is 15-30 min, and a cooling mode is water cooling; and (5) aging treatment is conducted on the steel plate which is subjected to solid solution by adopting a heat treatment technology scheme at the temperature of 300-650 DEG C, the aging time is 2-8 hours, and the cooling mode is air cooling after ageing is conducted.

Description

technical field [0001] Metallic materials and their processing methods. Background technique [0002] Precipitation hardening martensitic stainless steel obtains higher strength and hardness through the precipitation strengthening effect of Nb, Cu, Al, Ti elements, because this type of martensitic stainless steel has low carbon content and high corrosion resistance alloy, so it has very good corrosion resistance and welding performance. It has a very wide range of applications in industries such as surgical instruments. However, the smelting and casting process of this type of stainless steel is difficult, and the requirements for molten steel inclusions are high. At the same time, the product heat treatment process is complicated, and the main product technology is in the hands of foreign advanced enterprises. [0003] Martensitic stainless steel is a chromium-based stainless steel, which is widely used in fields such as knives, scissors, measuring tools, medical equipmen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/58C22C38/44C22C38/42C22C38/50C22C38/06C21D8/02

CPCC22C38/58C21D8/0226C21D8/0263C22C38/06C22C38/42C22C38/44C22C38/50

Inventor 秦斌黄明欣

Owner 上海落日新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com