Polyolefin material as well as preparation method and application thereof

A polyolefin and polyolefin resin technology, applied in the field of polyolefin materials and their preparation, can solve the problems of high cost, high dielectric loss of wave-transmitting performance, poor toughness, etc., to improve strength and heat resistance, and reduce density , The effect of improving the wave-transmitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-3

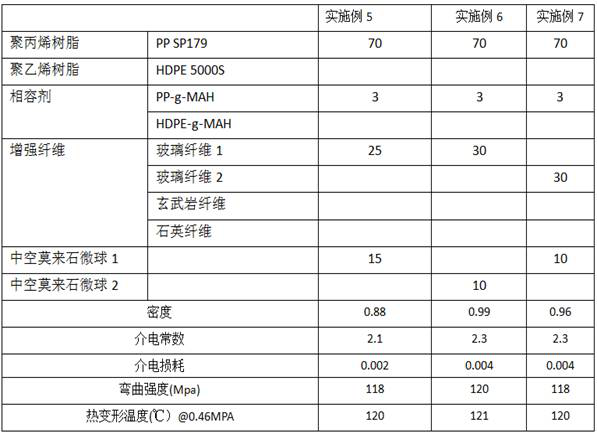

[0040] Mix the polyolefin resin and compatibilizer according to the ratio in Table 1, and add them to the main feeding system of the extruder, and at the same time add the reinforcing fiber and hollow mullite microspheres to the side feeding system, and mix all the components through the extruder The polyolefin material is obtained by extruding and granulating. The test results are shown in Table 1.

[0041] Each component distribution ratio (parts by weight) in the embodiment and comparative example of table 1

[0042]

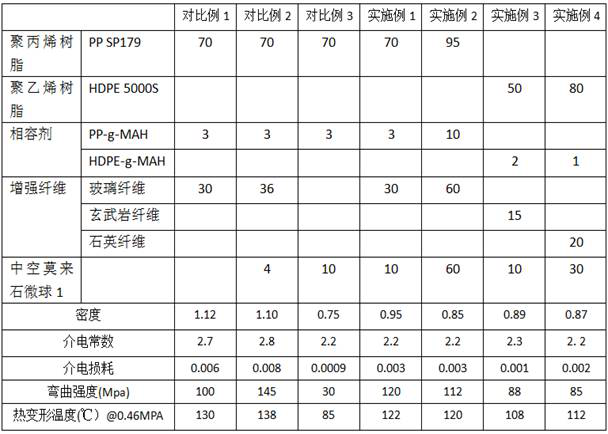

[0043] Continuation of Table 1:

[0044]

[0045] It can be seen from Comparative Example 1 that only adding reinforcing fibers, although the strength of the material is significantly improved, but its density is relatively high, and its wave-transmitting performance is poor. In comparative example 3, only hollow mullite microspheres were added, although its density decreased and its wave-transmitting performance was significantly improved, but its st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com