Glass fiber reinforced plastic radome and preparation method thereof

A fiberglass radome and glass fiber technology, which is applied in the field of radome, can solve the problems of increasing the difficulty and cost of transportation and installation, greatly affecting the wave-transmitting performance of the antenna, and increasing the production cost of the antenna, so as to reduce the total weight and enhance the wave-transmitting performance , the effect of good product surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

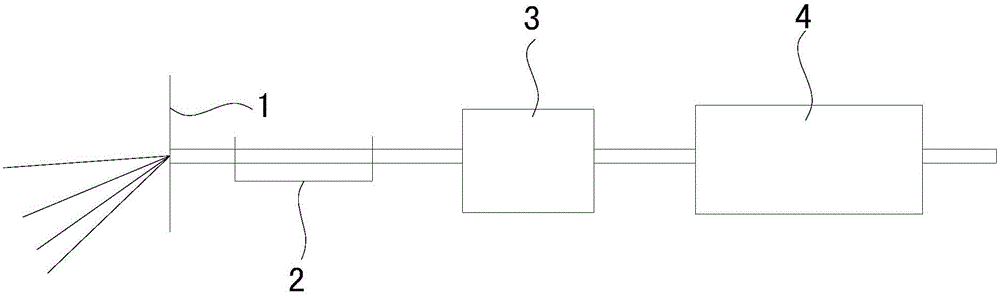

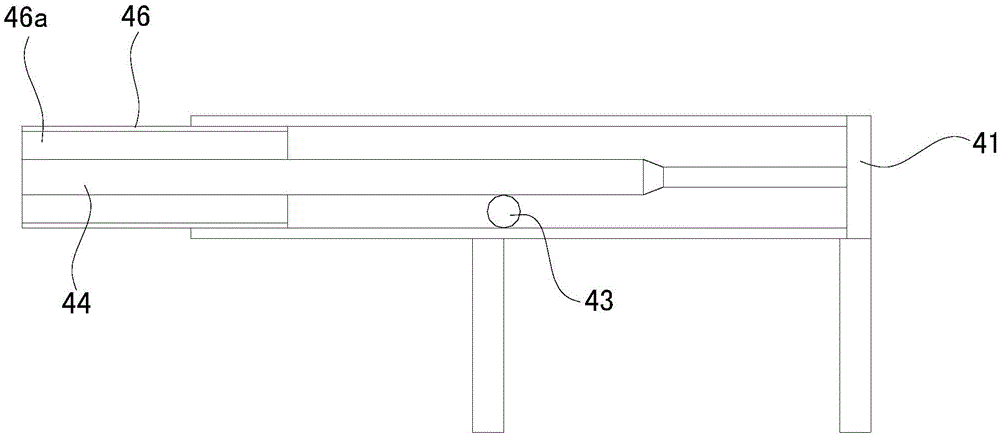

[0038] figure 1 It is a schematic flow sheet of the FRP radome production process in the embodiment of the present invention, as figure 1 Shown, the preparation method of FRP radome comprises the steps:

[0039] Step S1, release the glass fiber straight yarn, the glass fiber bulked yarn and the glass fiber felt through a yarn releasing device (not shown in the figure), and enter the thermosetting resin through the guide device 1 The resin tank 2. Preferably, when laying the yarns, a bundle of straight glass fiber yarns is separated from a bundle of bulky glass fiber yarns, so that straight glass fiber yarns and bulky glass fiber yarns are evenly mixed together. In the production process of the glass fiber reinforced plastic radome in the prior art, in order to increase the wettability of the yarn, the yarn passes through the resin tank, and the pressure roller in the resin tank forms artificial resistance when the glass fiber yarn passes through. However, the glass fiber ya...

Embodiment 1

[0045] Each raw material and weight percent thereof of the fiberglass radome in the present embodiment are as follows:

[0046] Glass fiber straight yarn 16%

[0047] Fiberglass bulked yarn 16%

[0048] Fiberglass Mat 15%

[0049] Epoxy bisphenol A modified vinyl resin 43%

[0050] Aluminum hydroxide 10%.

[0051] The preparation method adopts the conventional preparation method or the preparation method described in the above examples. After testing, the density of the FRP radome obtained in this example is 1.75g / cm 3 , The dielectric constant is 3.8.

Embodiment 2

[0053] Each raw material and weight percent thereof of the fiberglass radome in the present embodiment are as follows:

[0054] Glass fiber straight yarn 12%

[0055] Fiberglass bulked yarn 12%

[0056] Fiberglass Mat 18%

[0057] Epoxy bisphenol A modified vinyl resin 46%

[0058] Aluminum hydroxide 12%.

[0059] The preparation method adopts the conventional preparation method or the preparation method described in the above examples. After testing, the density of the FRP radome obtained in this example is 1.65g / cm 3 , The dielectric constant is 3.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com