Metamaterial and preparation method thereof

A technology of metamaterials and casting sheets, applied in the direction of electrical components, antennas, etc., can solve the problems of quartz ceramic matrix loss and low strength of quartz ceramic matrix metamaterials, and achieve low loss, high strength, and high wave-transmitting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

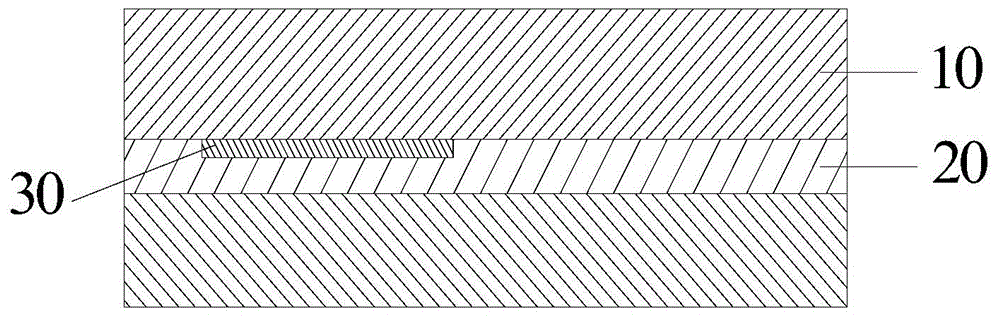

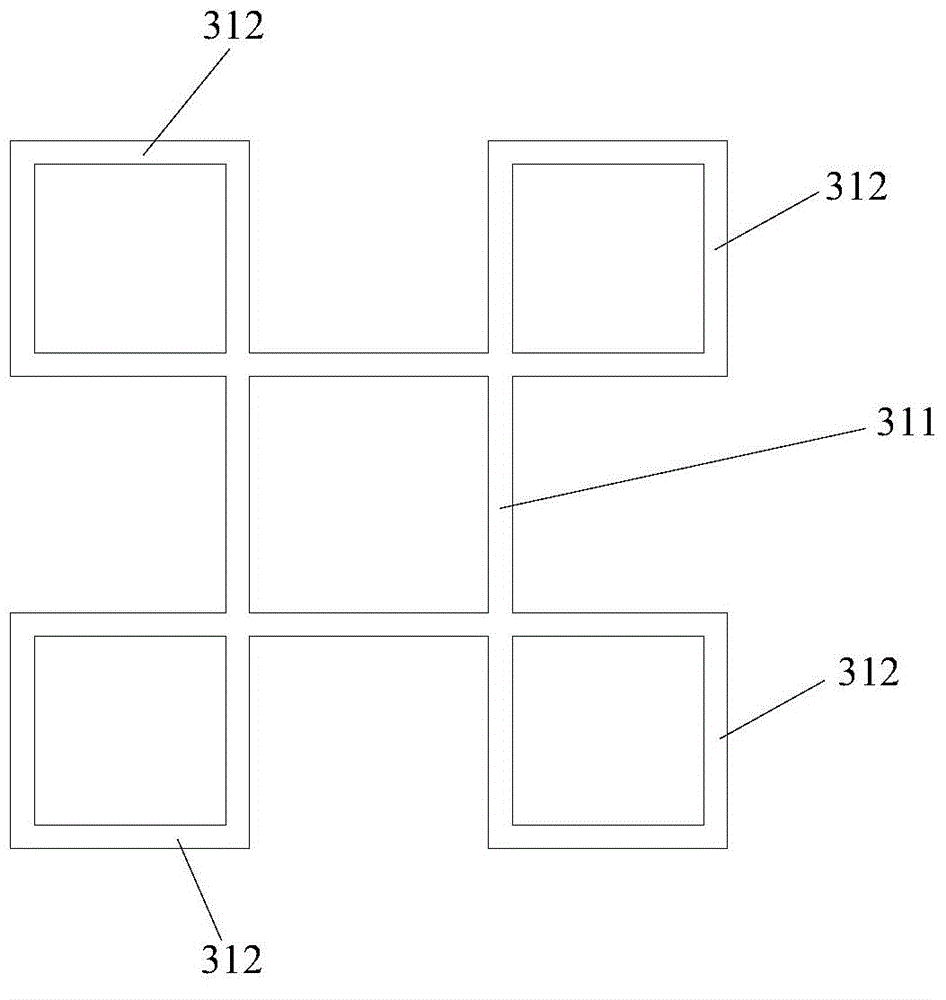

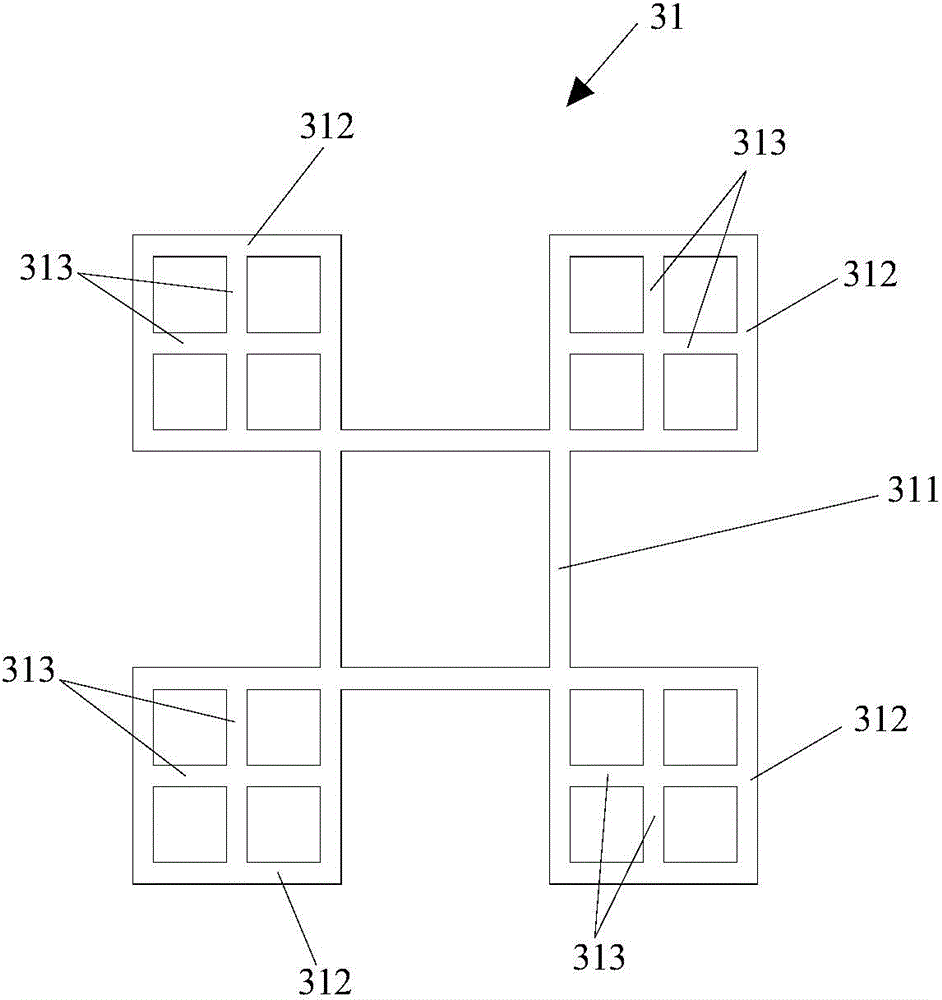

[0043] According to another aspect of the present invention, a method for preparing a metamaterial is provided, such as Figure 7 shown. The preparation method comprises the steps of: compounding the silica sol-based slurry with quartz fibers to form a fiber composite body, and forming a metal microstructure on the surface of a casting sheet body; The blank body is pressed to form a preliminary metamaterial; the preliminary metamaterial is sintered, so that the fiber composite is sintered into a silica fiber reinforced silica matrix, and the casting sheet blank is sintered into a casting sheet, and the quartz fiber The reinforced silica matrix constitutes the substrate, and the cast sheet, metal microstructure and substrate constitute the metamaterial.

[0044] In the above preparation method, the silica sol-based slurry is compounded with quartz fibers and sintered to form a quartz fiber-reinforced silica matrix, and the quartz fiber-reinforced silica matrix constitutes the ...

Embodiment 1

[0057] The steps of the preparation method of the metamaterial provided in this embodiment include:

[0058]First, add quartz powder to the silica sol, and then adjust the pH value to 9 to form a silica sol-based slurry, and the weight percentage of quartz powder in the silica sol-based slurry is 15wt%; The material is combined with quartz fibers to form a fiber composite body, and a metal microstructure is formed on the surface of the casting sheet blank; The hot-pressing temperature is 500°C and the hot-pressing time is 0.1 hour to form the preliminary metamaterial; then, the preliminary metamaterial is sintered at 900°C for 2 hours to sinter the fiber composite The quartz fiber reinforced silica matrix is sintered into the casting sheet, and the quartz fiber reinforced silica matrix constitutes the substrate, and the metal microstructure, casting sheet and substrate constitute the metamaterial, wherein the quartz fiber reinforced The silica fiber accounts for 20% by weig...

Embodiment 2

[0060] The steps of the preparation method of the metamaterial provided in this embodiment include:

[0061] First, add quartz powder to the silica sol, then adjust the pH value to 9 to form a silica sol-based slurry, add a sintering aid to the silica sol-based slurry, and the weight percentage of the quartz powder in the silica sol-based slurry is 5wt%, and the sintering aid accounted for 1wt% of the weight percentage of the silica sol-based slurry; the silica sol-based slurry was combined with the quartz fiber to form a fiber composite by the impregnation method, and the second fiber composite was prepared under the same conditions Form metal microstructure on the surface of the cast sheet green body, the cast sheet green body with metal microstructure is arranged between two fiber composites, and the hot pressing pressure is 2 atmospheres, and the hot pressing temperature is 1500 ° C, and pressing under the condition of hot pressing time of 6 hours to form a preliminary met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com