A kind of preparation method of diamond composite material

A composite material and diamond technology, used in metal processing equipment, coating, transportation and packaging, etc., can solve the problem of high interface, achieve high dimensional accuracy, high corrosion resistance, improve hardness and fracture toughness effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

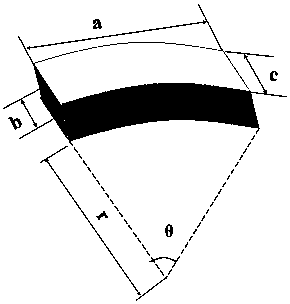

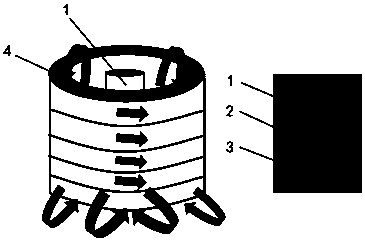

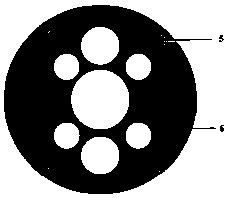

[0029] The preparation method of diamond composite material described in the present embodiment specifically comprises the following steps:

[0030] (1) Ultrasonic treatment of diamond particles (with a particle size of 90 μm) in acetone solution, cleaning and rinsing with distilled water; then weigh the cleaned diamond particles, add binder and mix well, then add nickel-chromium alloy powder for Stir to make it evenly coated on the surface of the diamond particles, and then place it at a temperature of 200 ° C for 1 hour to obtain pretreated diamond particles; wherein the volume ratio of diamond particles is 90%, and the volume ratio of nickel-chromium alloy powder is 8%, and the volume ratio of the binder is 2%.

[0031] (2) Use XQM-4L planetary ball mill for ball milling of the mixed powder, set the speed of the ball mill to 300r / min, and mix the diamond particles obtained in step (1) with high manganese steel powder (particle size: 250μm) for ball milling to obtain the mix...

Embodiment 2

[0038] The preparation method of diamond composite material described in the present embodiment specifically comprises the following steps:

[0039] (1) Ultrasonic treatment of diamond particles (with a particle size of 80 μm) in acetone solution, cleaning and rinsing with distilled water; then weigh the cleaned diamond particles, add binder and mix well, then add nickel-chromium alloy powder for Stir to make it evenly coated on the surface of the diamond particles, and then place it at a temperature of 250 ° C for 2 hours to obtain pretreated diamond particles; wherein the volume ratio of diamond particles is 80%, and the volume ratio of nickel-chromium alloy powder is 15%, and the volume ratio of binder is 5%.

[0040] (2) Use XQM-4L planetary ball mill for ball milling of the mixed powder, set the speed of the ball mill to 150r / min, and mix the diamond particles obtained in step (1) with high manganese steel powder (particle size: 380μm) for ball milling to obtain the mixed...

Embodiment 3

[0045] The preparation method of diamond composite material described in the present embodiment specifically comprises the following steps:

[0046] (1) Ultrasonic treatment of diamond particles (with a particle size of 100 μm) in acetone solution, cleaning and rinsing with distilled water; then weigh the cleaned diamond particles, add binder and mix well, then add nickel-chromium alloy powder for Stir to make it evenly coated on the surface of diamond particles, and then place it at a temperature of 230 ° C for 1.5 hours to obtain pretreated diamond particles; the volume ratio of diamond particles is 85%, and the volume ratio of nickel-chromium alloy powder is 12%, and the volume ratio of the binder is 3%.

[0047] (2) Use XQM-4L planetary ball mill for ball milling of the mixed powder, set the speed of the ball mill to 150r / min, mix the diamond particles obtained in step (1) with high manganese steel powder (particle size is 10μm) and ball mill to get the mixed powder , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com