High-wave-transparent porous quartz/quartz ceramic-based composite material and preparation method thereof

A technology of composite materials and quartz ceramics, applied in ceramic products, other household appliances, applications, etc., can solve problems such as insufficient wave-transmitting performance, and achieve the effect of improving wave-transmitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

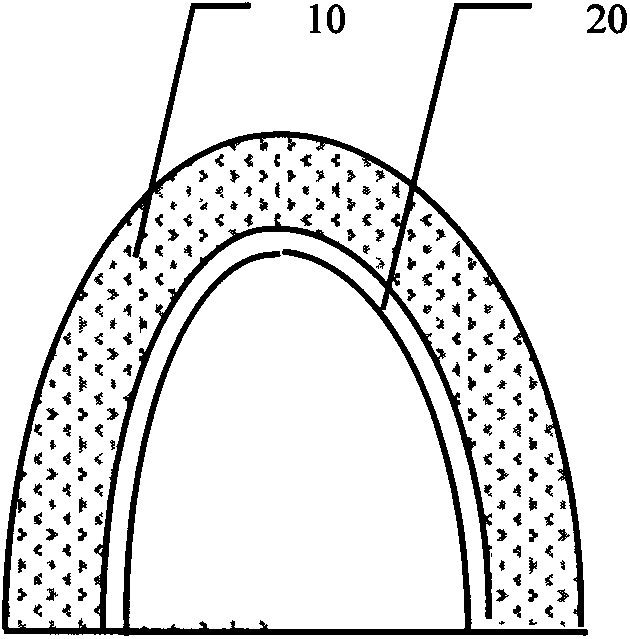

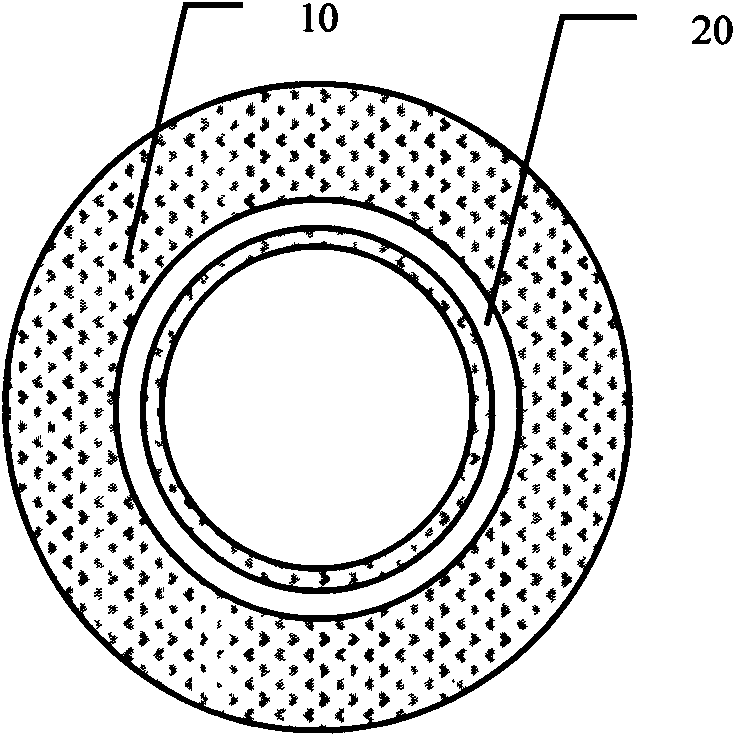

[0017] figure 1 It is a cross-sectional view of a highly transparent porous quartz / quartz ceramic matrix composite material. Among them, [10] is a quartz / quartz composite material layer composed of quartz fiber reinforcement and quartz matrix, and [20] is a channel, which is characterized in that the channel is uniformly present in the part of the quartz / quartz ceramic matrix composite near the inner surface. The channel is circular with a diameter of 1 mm, and the distance between the channel layer and the inner surface is 5 mm. The volume ratio of pores to the whole material is 20%. The shape of the channels is linear, and the channels are distributed parallel to each other.

[0018] The preparation method of the above-mentioned highly transparent porous quartz / quartz ceramic matrix composite material, the specific steps are as follows:

[0019] (1) The pure iron wire is prefabricated in the reinforced structure formed by quartz fiber weaving or lamination, and the pure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com