Insulating tape material, method for production and usage thereof

A technology of insulating tape and particles, applied in the field of insulating tape materials such as mica paper, and manufacturing electrical insulating paper, can solve the problem of thermal conductivity limitation of the total system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

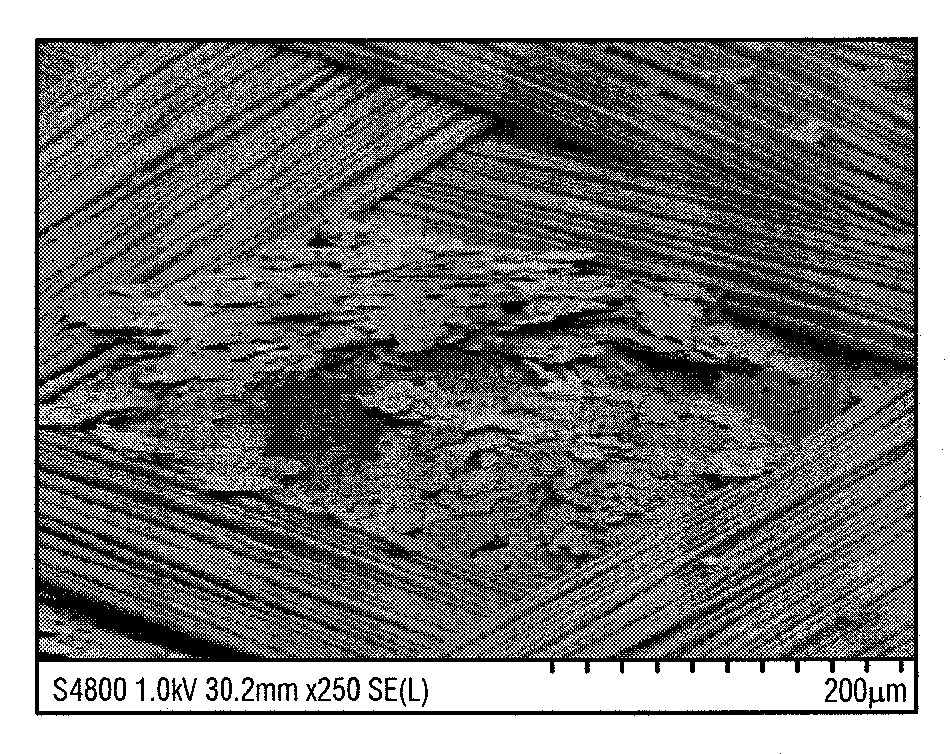

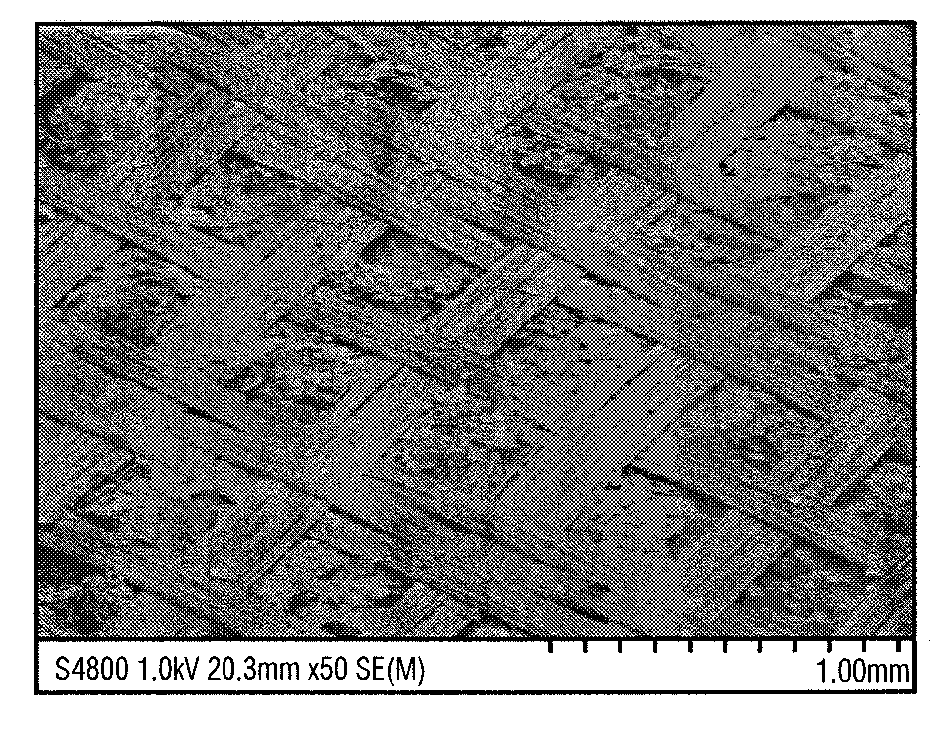

[0031] The meshes shown are filled according to the prior art with a binding material which generally has poor thermal conductivity, since the recombination between the platelet-shaped particles and the fabric occurs only after the production of the (advantageously porous) particle composite according to EP11164882 It is done by attaching mesh fabric and adhesive.

[0032]The present invention relates to an insulating tape material, a method of manufacture and its use, in particular an insulating tape material for the manufacture of electrical insulating papers, such as mica paper, which are contained in heat-conducting insulating tapes, such as in used for high voltage insulation. The insulating tape material has fiber reinforcement by a fabric, the meshes of which are filled by a (preferably thermally conductive) particle composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com