Large oil-immersed transformer insulated end ring and manufacturing technology thereof

An oil-immersed transformer and manufacturing process technology, applied in the field of transformers, can solve the problems of affecting the production cycle, scrapping and redoing parts, delaying delivery, etc., and achieve the effects of reducing partial discharge, strong practicability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

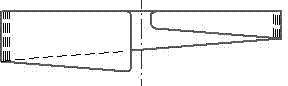

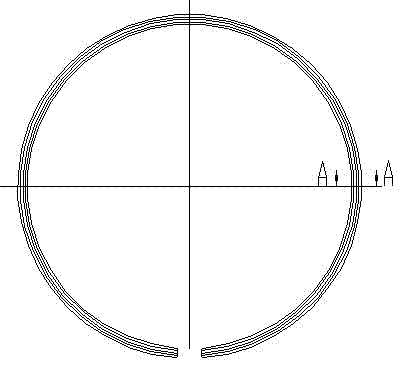

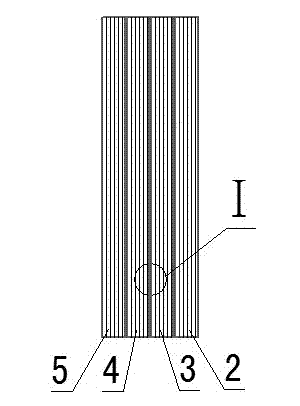

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

[0018] The large-scale oil-immersed transformer insulating end ring of the present invention includes a casein glue layer 1 and several layers of cardboard, and two adjacent layers of cardboard are bonded through the casein glue layer. Choose the number of layers of cardboard according to the drawing and the thickness of the cardboard used.

[0019] The preferred solution of the large oil-immersed transformer insulation end ring of the present invention is that the cardboard includes four layers, namely the first layer of cardboard 5 , the second layer of cardboard 4 , the third layer of cardboard 3 , and the fourth layer of cardboard 2 .

[0020] The manufacturing process of the large oil-immersed transformer insulating end ring of the present invention includes the following steps:

[0021] A. First, according to the requirements of the drawing, use a shearing machine to cut a certain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com