Built-in transformer of wind power tower barrel

A wind power tower, built-in technology, applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problems of increased operating cost, poor installation and operation reliability, energy waste of wind field substation, etc. , to achieve the effect of reducing hysteresis consumption, improving product life, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

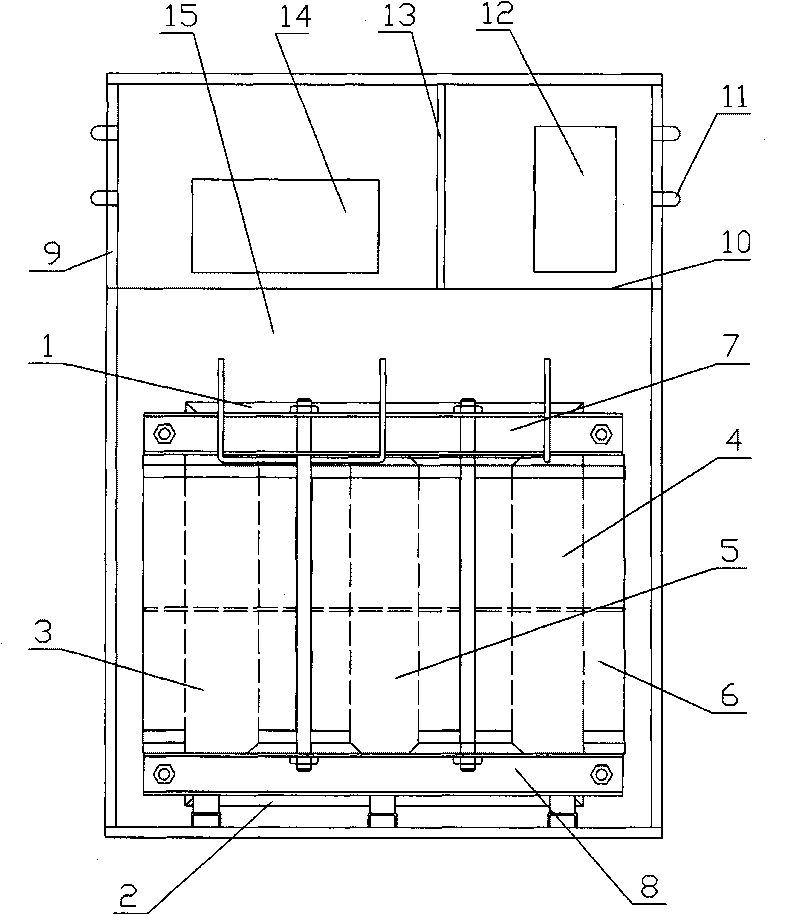

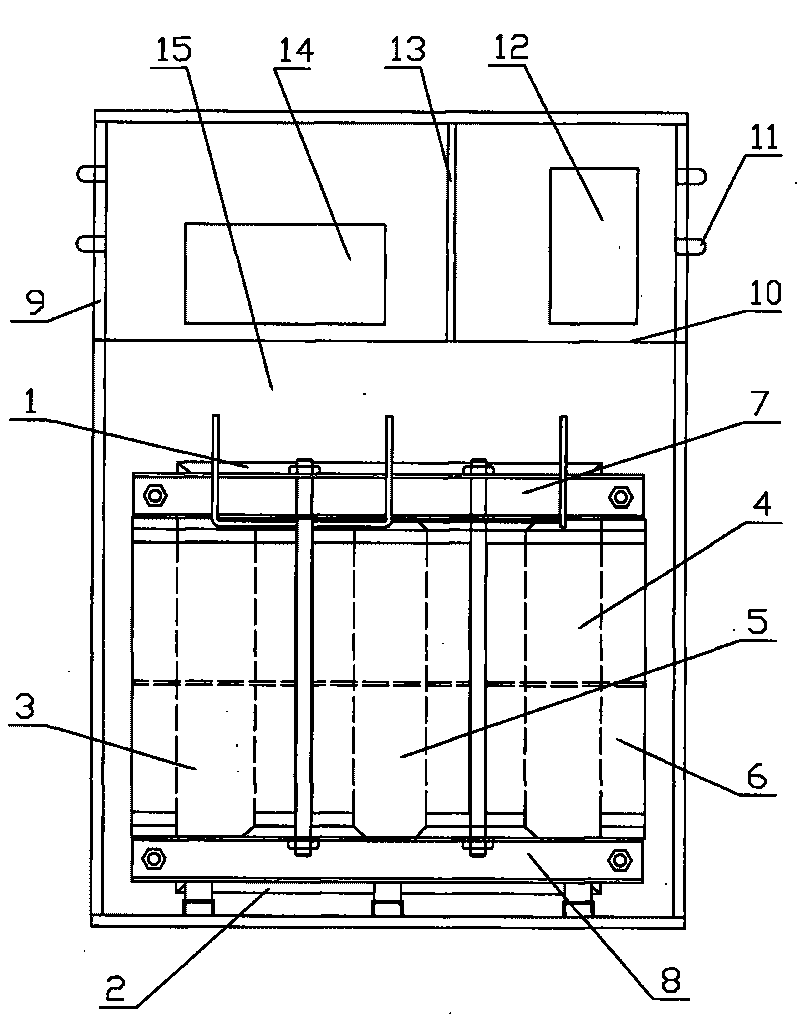

[0020] Marks in the figure: 1. Upper iron yoke, 2. Lower iron yoke, 3. Left column, 4. Right column, 5. Middle column, 6. Whole winding, 7. Upper clamp, 8. Lower clamp, 9. Shell, 10. Transverse partition, 11. Elbow cable terminal connector, 12. Low voltage room, 13. Median partition, 14. High voltage room, 15. Transformer room.

[0021] As shown in the figure, this built-in wind power tower transformer includes a low-voltage winding, a high-voltage winding, an iron core, an upper clamp, and a lower clamp, wherein the iron core is provided with an upper iron yoke 1, a lower iron yoke 2, and an upper iron yoke There is a left column 3 at the left end between the lower iron yoke 2, and the upper and lower ends of the left column 3 overlap with the left ends of the upper iron yoke 1 and the lower iron yoke 2 respectively; the right ends of the upper iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com