Patents

Literature

37results about How to "Reduce discharge phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery discharge control method and device

ActiveCN102403767AImprove performanceReduce discharge phenomenonBatteries circuit arrangementsElectric powerEmbedded system

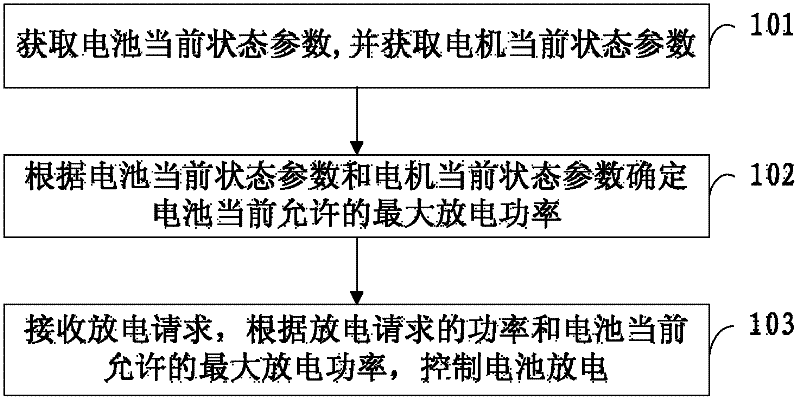

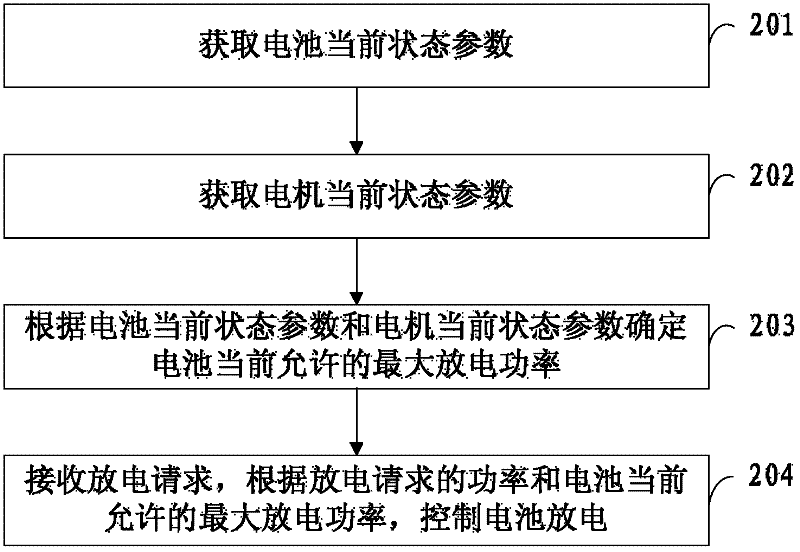

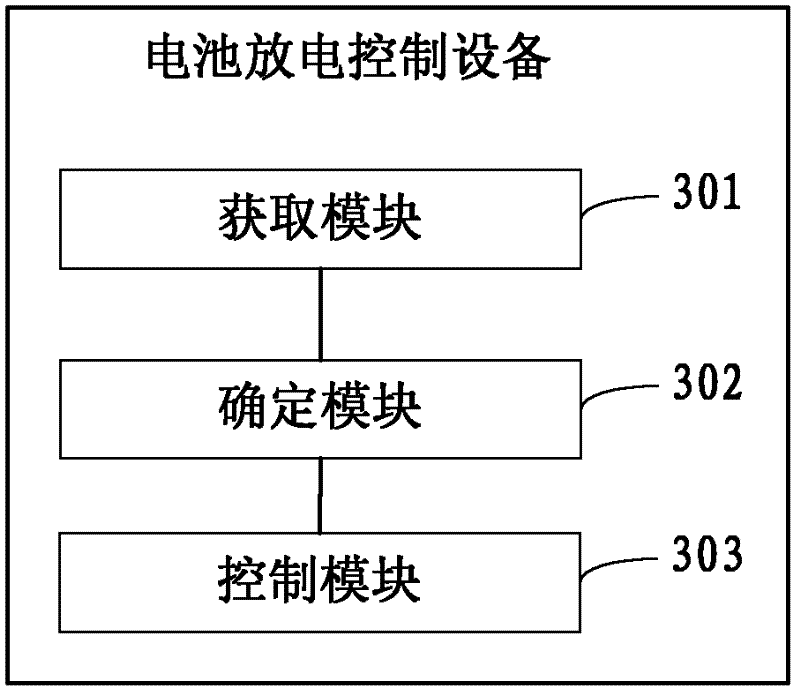

The invention discloses a battery discharge control method and device, which relates to the control field. The method comprises the following steps of: obtaining a current status parameter of a battery, and obtaining a current status parameter of a motor; determining maximal discharge power currently allowed by the battery according to the current status parameter of the battery and the current status parameter of the motor; and receiving a discharge request, and controlling the battery to discharge according to the power of the discharge request and the maximal discharge power currently allowed by the battery. The battery discharge method and device provided by the invention control the battery to discharge according to the power of the discharge request and the maximal discharge power currently allowed by the battery so as to reduce battery overdischarge phenomenon and enhance battery performance.

Owner:CHERY AUTOMOBILE CO LTD

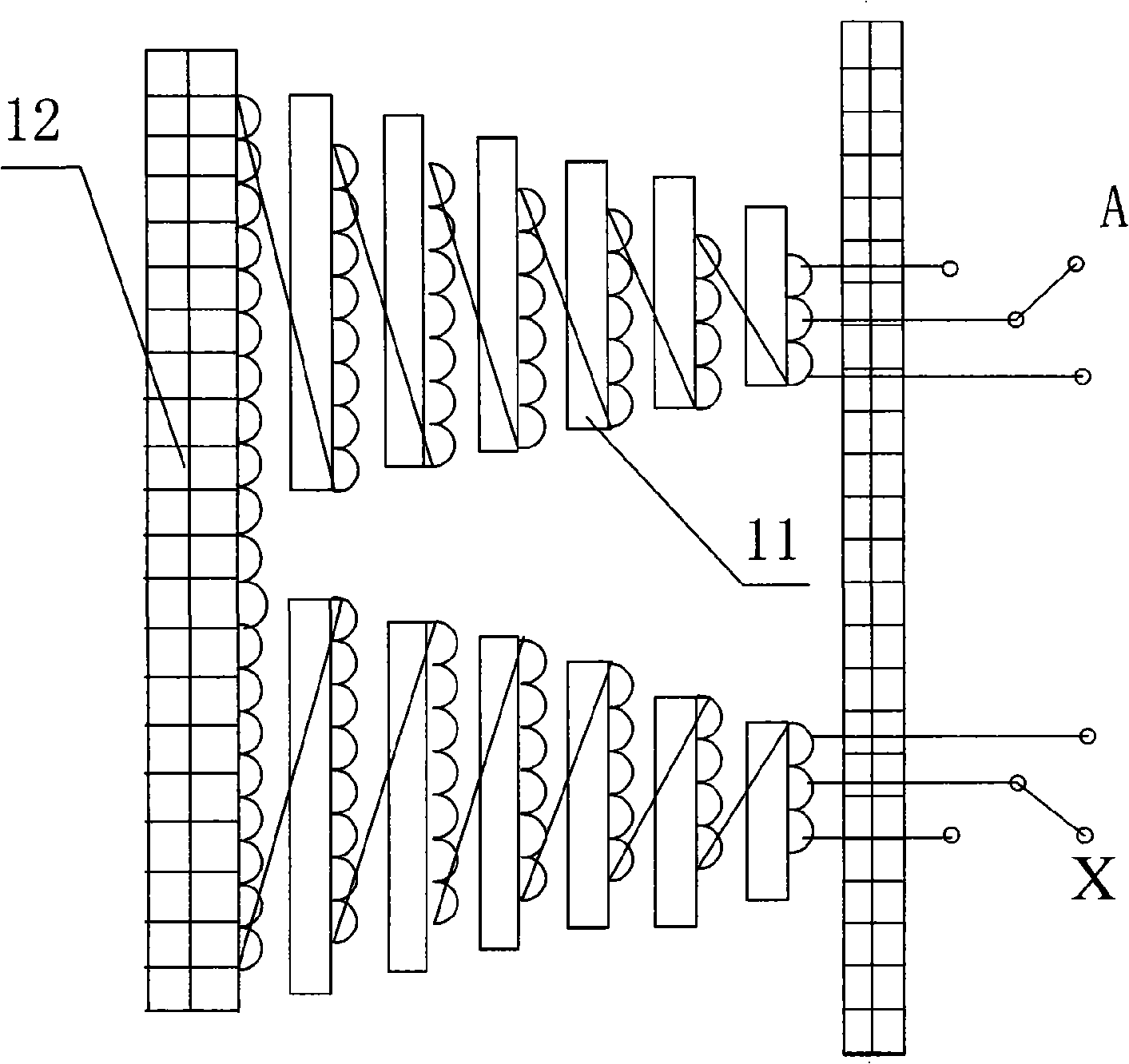

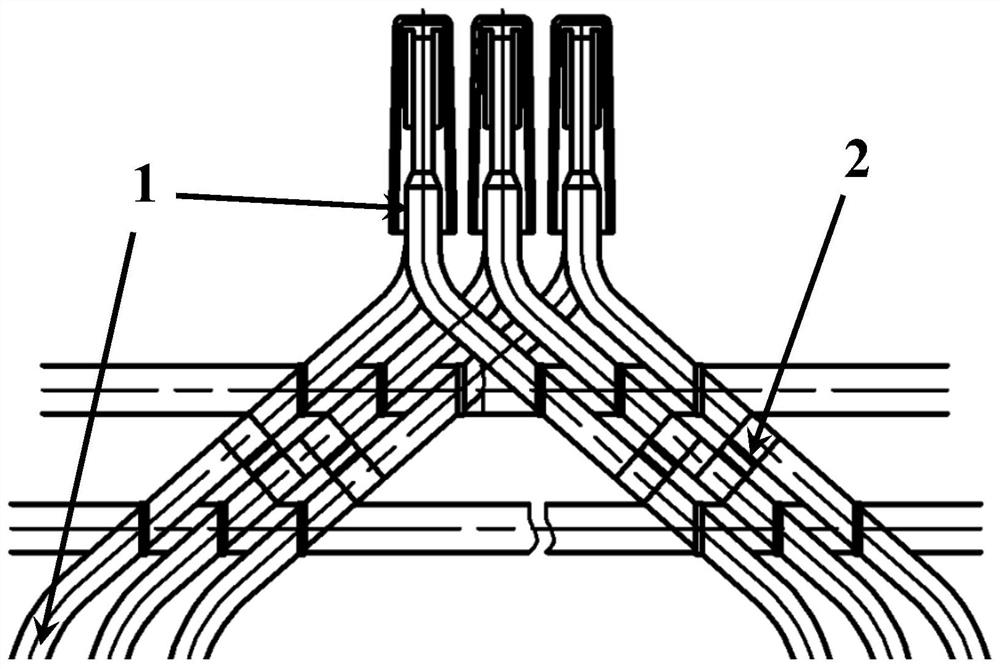

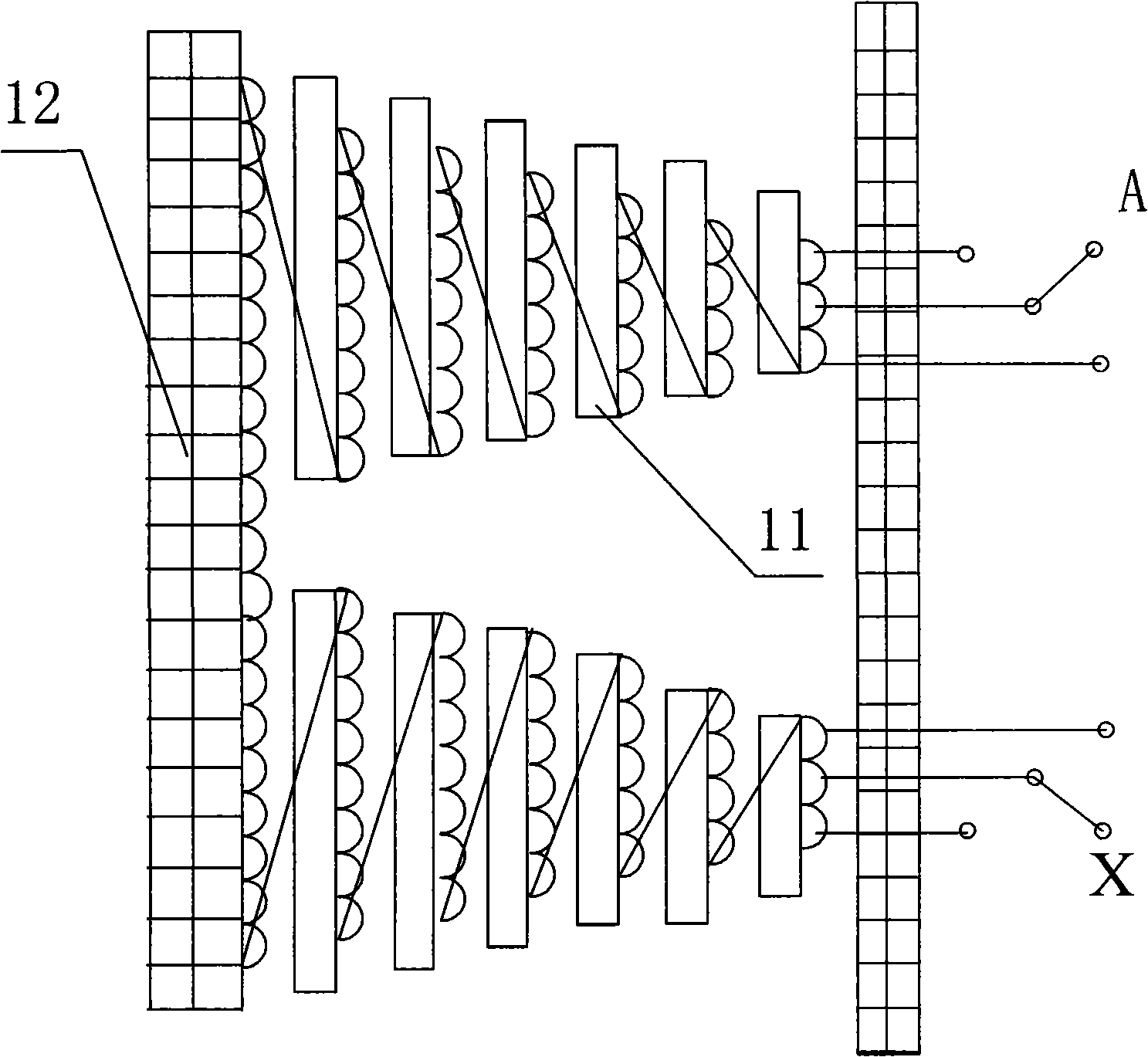

Epoxy cast dry transformer

InactiveCN101308721AReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyLow voltage

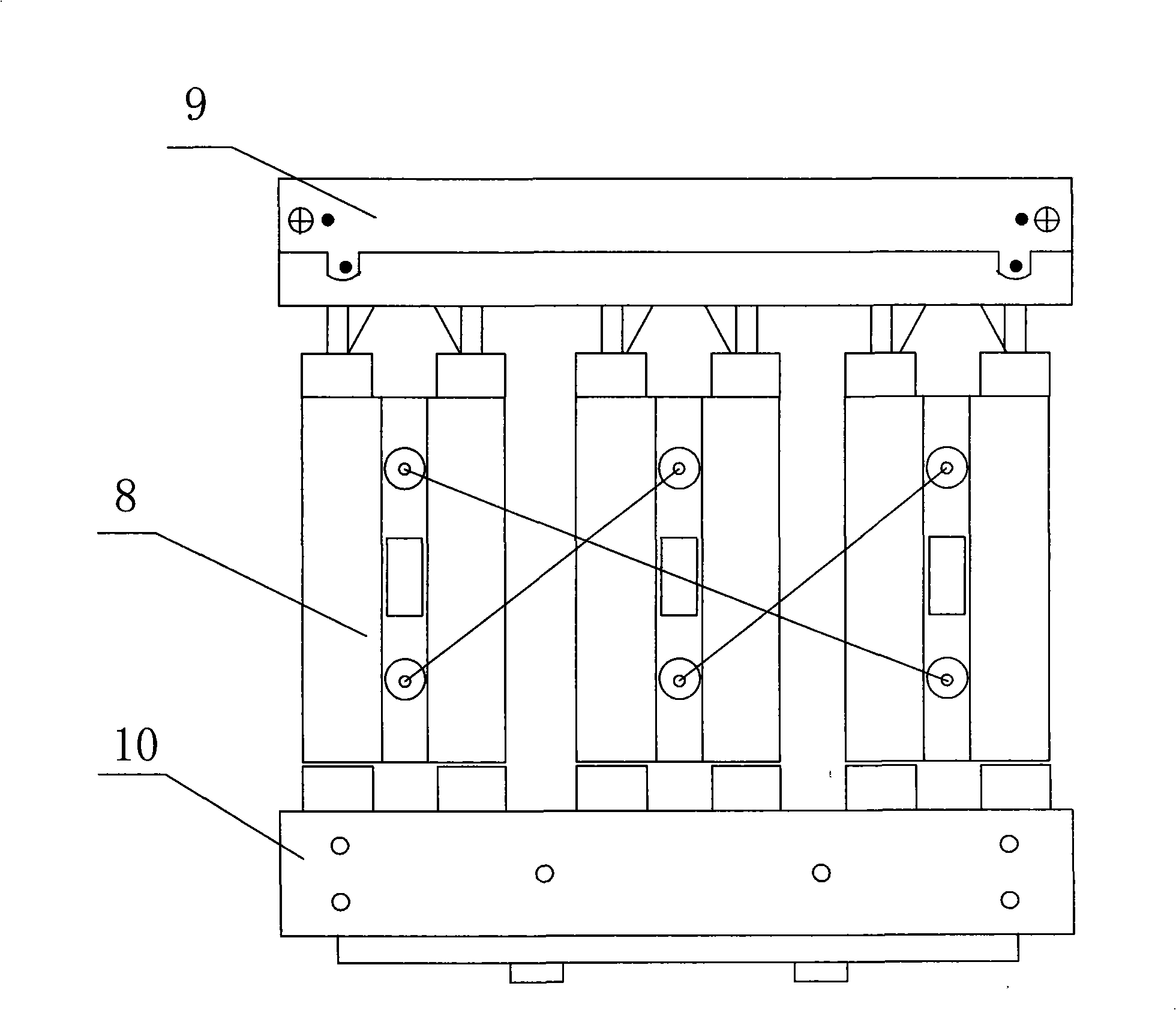

Disclosed is an epoxy resin cast dry type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp, and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to the outer layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost and requires no daily maintenance. The epoxy resin cast dry type transformer is of strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

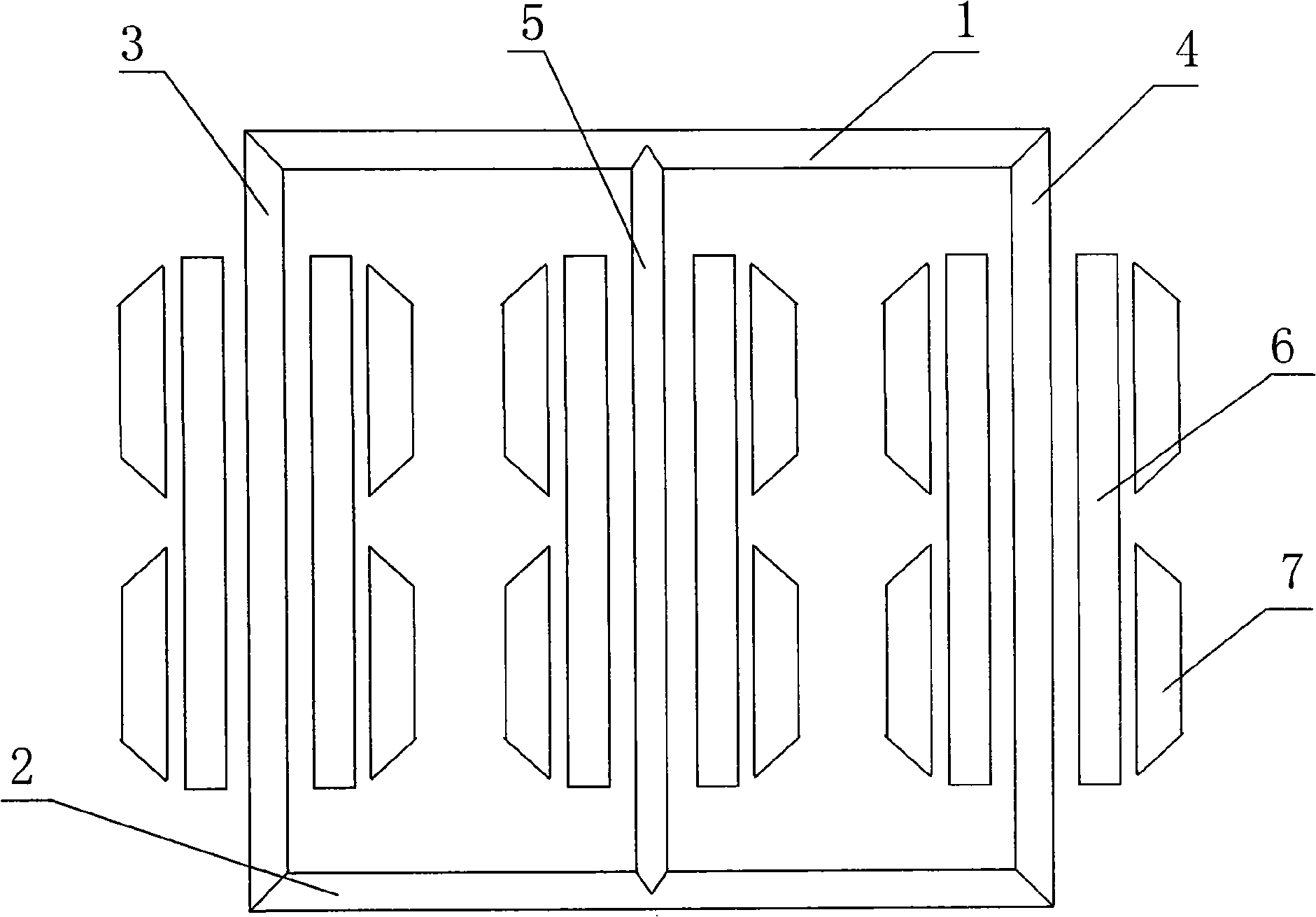

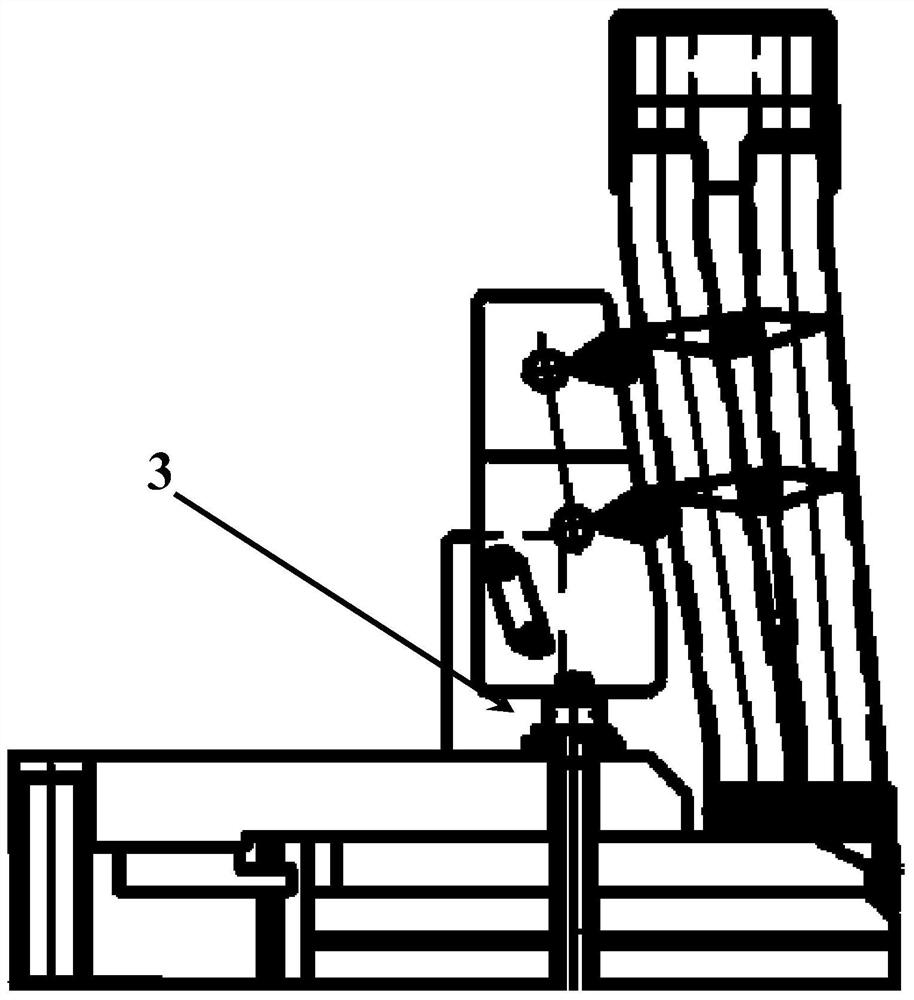

Honeycomb electrofilter with high flow rate

ActiveCN103817009AImprove efficiencyIncrease electric powerElectrode carrying meansElectric supply techniquesTarHoneycomb

The invention relates to the technical field of electric filtration and purification, in particular to a honeycomb electrofilter with a high flow rate. According to the honeycomb electrofilter, a power supply control cabinet is connected with a high pressure generator connected with china bottle pull rods; sleeve insulating boxes are arranged at the top of a cylinder; sleeve insulating pieces and the china bottle pull rods are fixedly connected to form a whole and are fixedly connected with an upper hanging bracket, the upper hanging bracket is connected with a barb corona electrode, both a collecting electrode and the barbed corona electrode are arranged between the upper hanging bracket and a lower hanging bracket, and gas distribution plates are arranged below the lower hanging bracket; and an anti-swing suspension, the barbed corona electrode, the collecting electrode and the gas distribution plates are arranged in the cylinder, a gas inlet is formed in the lower part of one side of the cylinder, a gas outlet is formed in the center of the top of a tar precipitating body, and a tar outlet is formed in the lower part of the cylinder. According to the honeycomb electrofilter, the electrofiltration and purification problems of gas when the air speed of a gas electric field is 3-4 m / s are solved, the steel consumption of an equipment body is reduced, and at the same time, the corona power of the electric field is increased, so that the electrofiltration efficiency is improved.

Owner:XIANGYANG JIUDING HAOTIAN ENVIRONMENTAL PROTECTION EQUIP

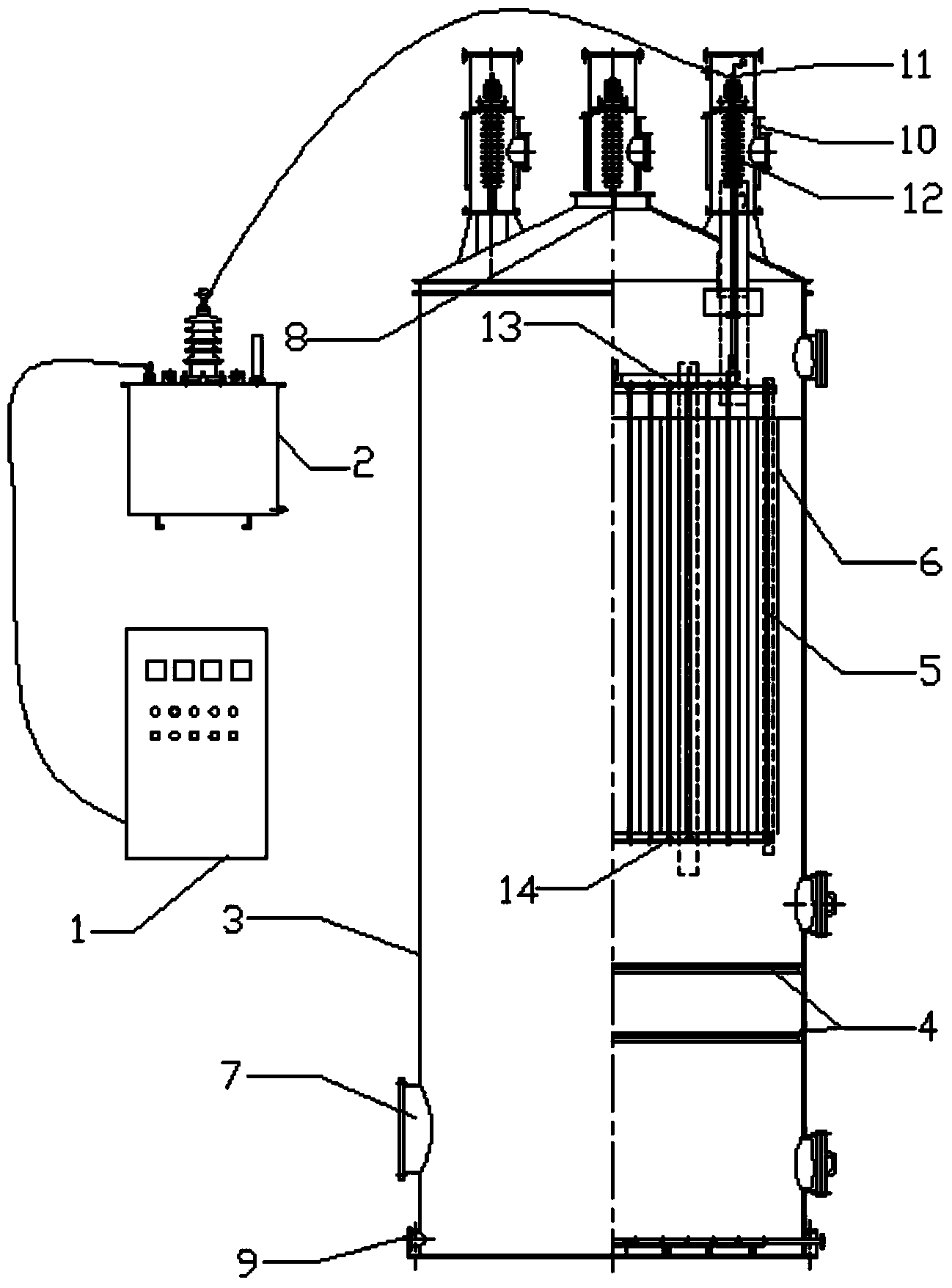

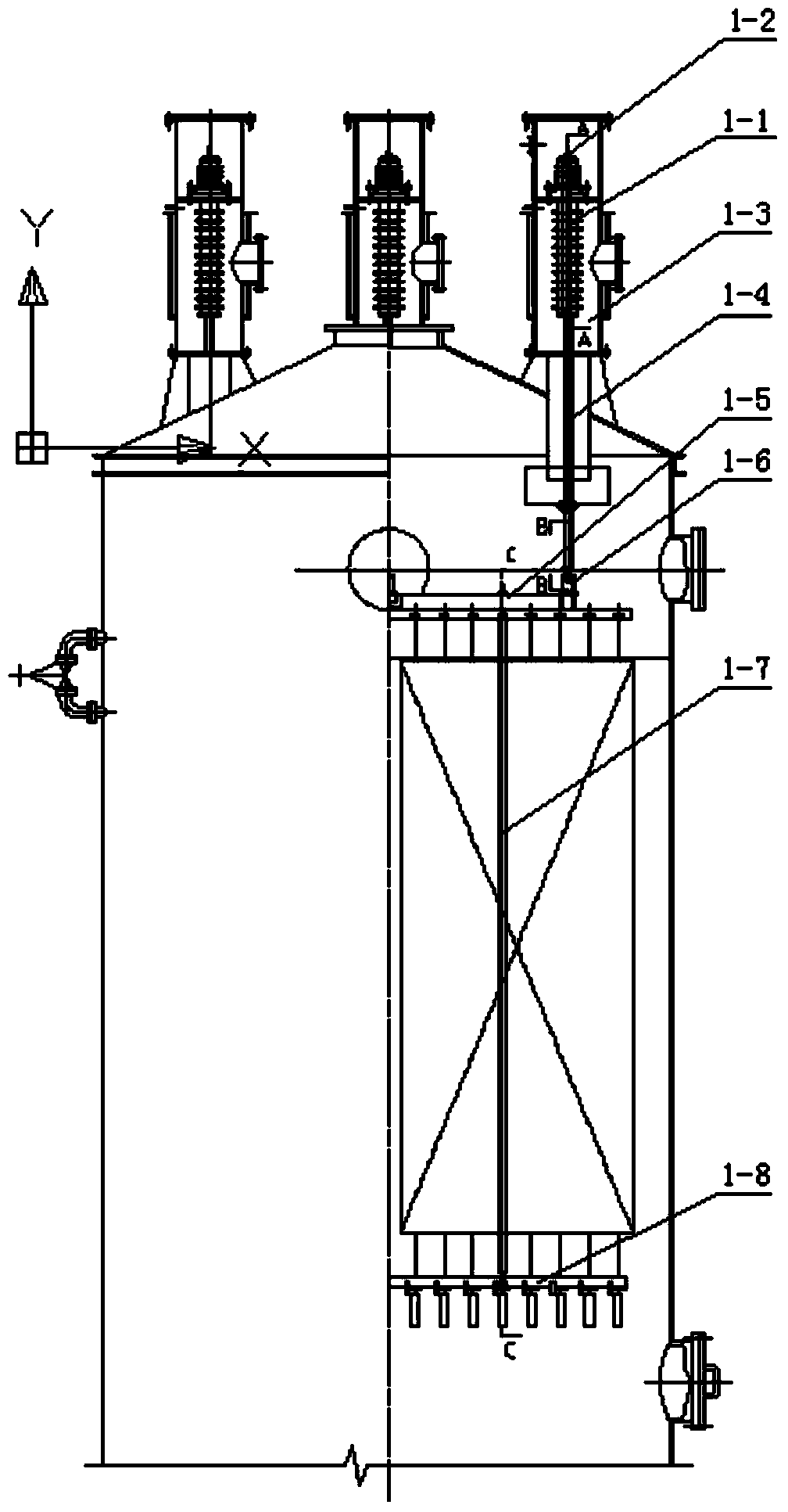

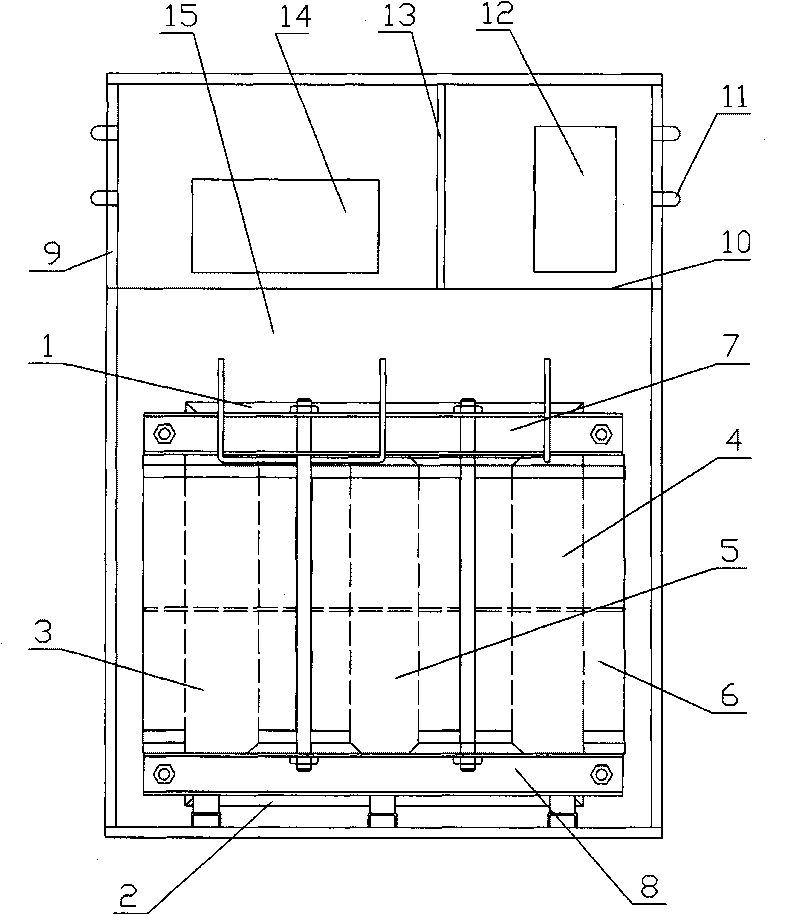

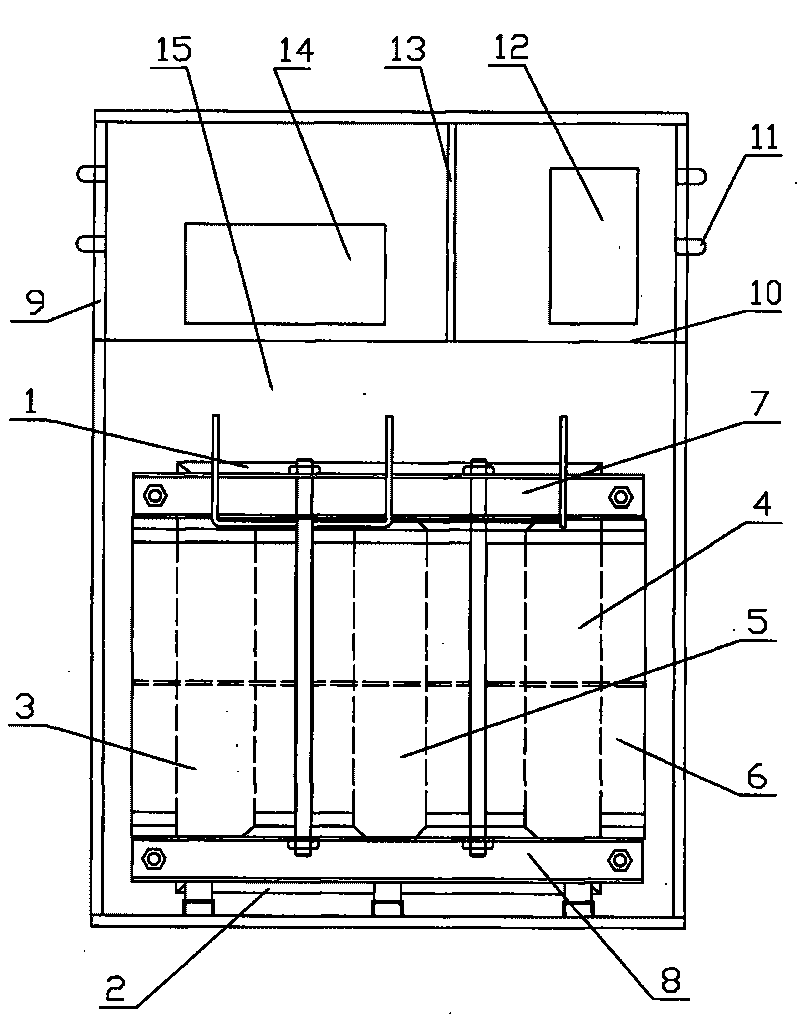

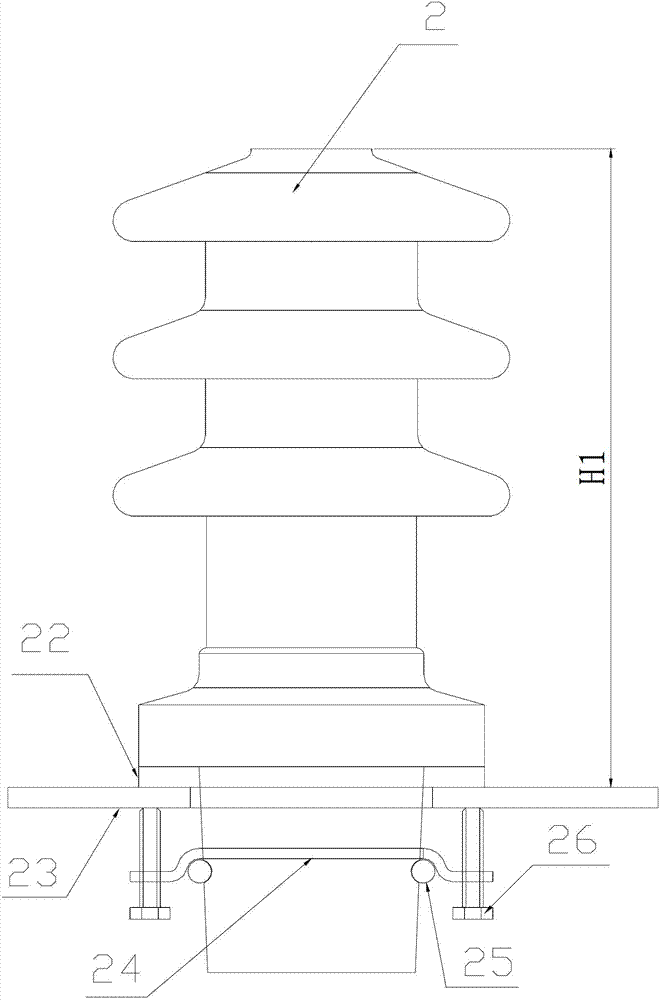

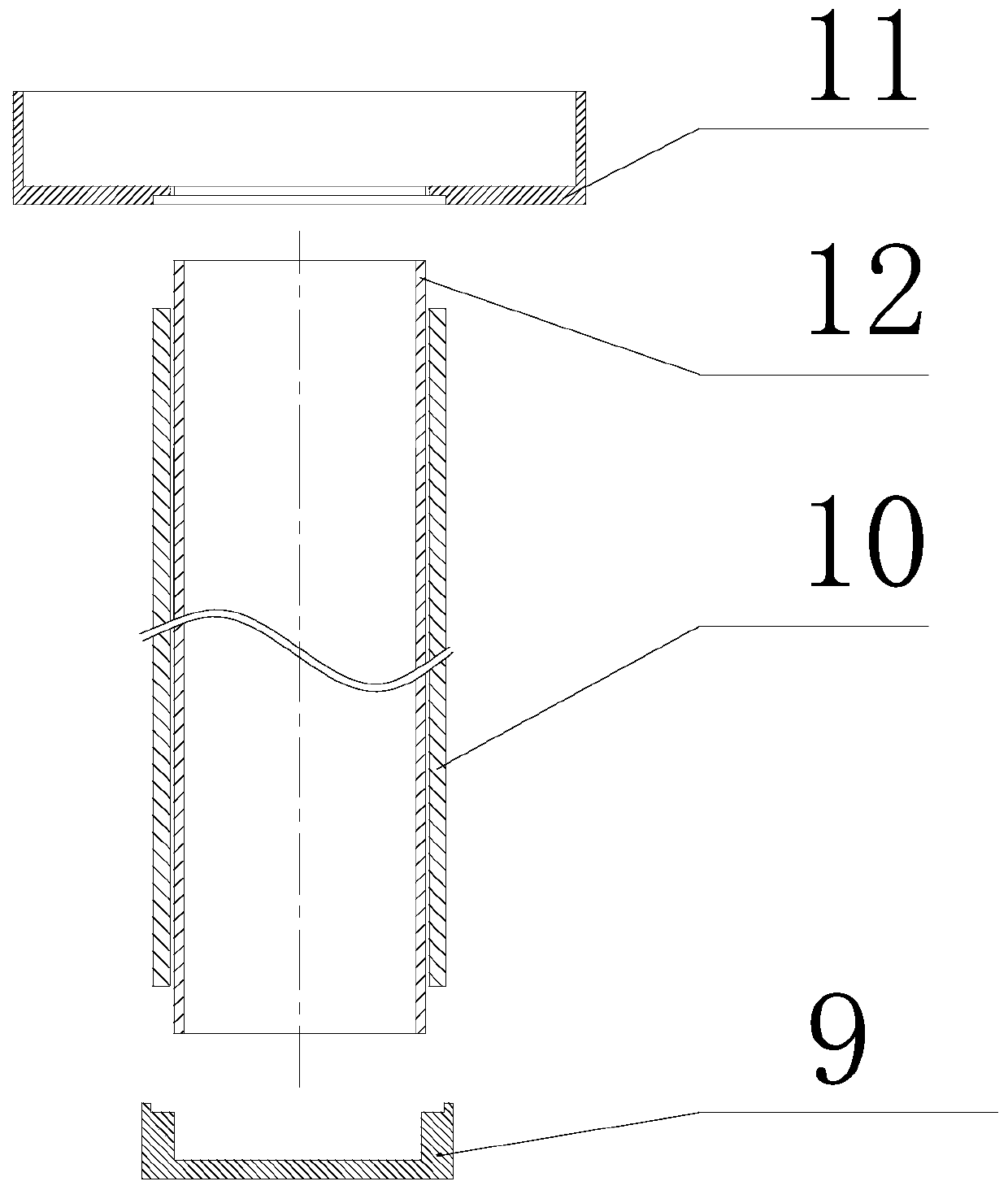

Built-in transformer of wind power tower barrel

InactiveCN101740202AReduce hysteresis consumptionHigh dielectric strengthTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow noiseLow voltage

The invention provides a built-in transformer of a wind power tower barrel, comprising a low-voltage winding, a high-voltage winding and an iron core. The structural key points are as follows: the iron core is provided with an upper iron yoke and a lower iron yoke; a side column is respectively arranged between the left end and the right end of the upper iron yoke and the lower iron yoke; the upper and lower ends of the side column are respectively connected with the left end and the right end of the iron yoke in an overlapping manner; the middle part of the iron yoke is provided with a middle column; the upper end and the lower end of the middle column are respectively connected with the middle part of the iron yoke in an overlapping manner; the side column and the middle column are respectively provided with the winding; the inner layer of the winding is provided with low-voltage coil; the outer layer of the low-voltage coil is sheathed with a high-voltage coil; clamping units are respectively arranged at the front and rear sides of the iron yoke; the low-voltage coil is wound with a copper foil; the materials pre-impregnated by DMD resin is used as the insulation between layers; a flexible grid cloth is arranged between two adjacent layers of the high-voltage winding; and the periphery of the high-voltage is provided with the solventless grid materials. The invention is characterized by compact structure, long service life, low noise, free maintenance, high reliability, no pollution, flame retardancy and the like, the probability of partial discharge is approximately zero, and the invention can be recycled after the service life is ended up.

Owner:沈阳福林特种变压器有限公司

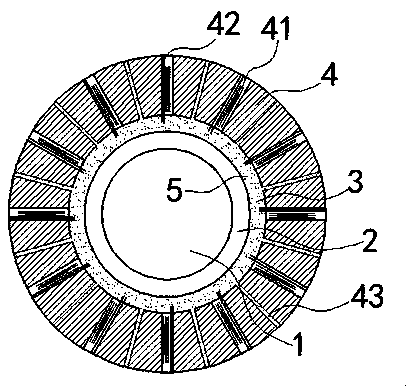

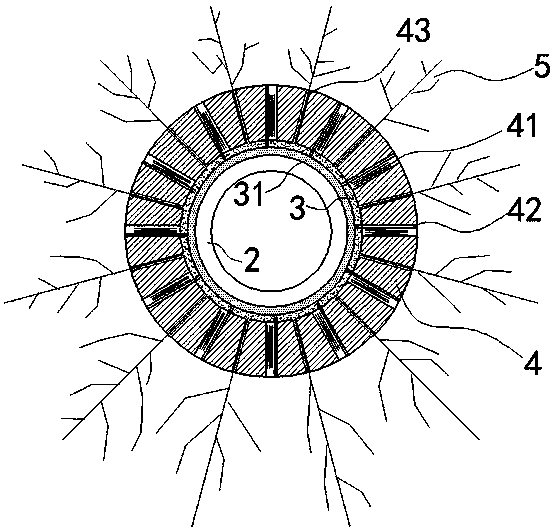

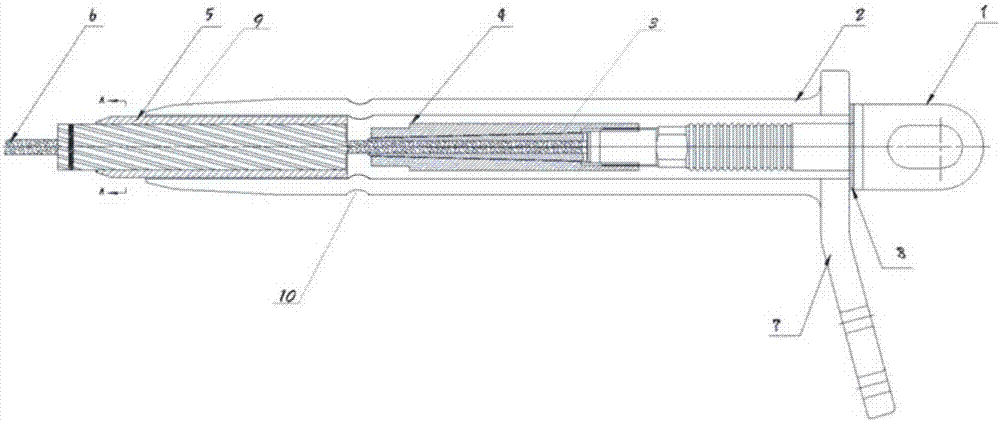

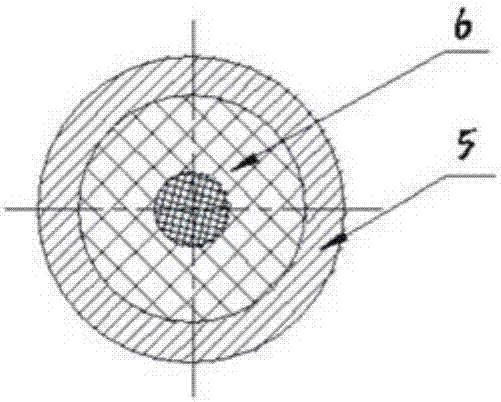

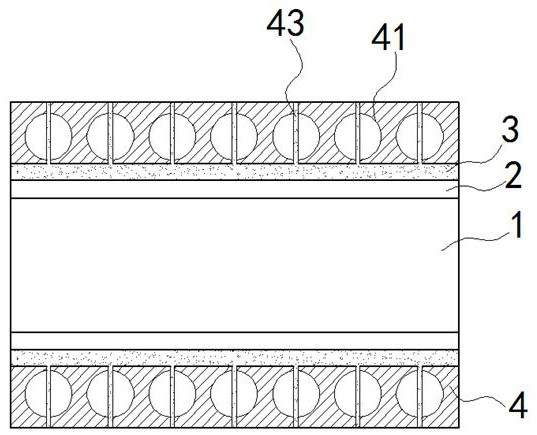

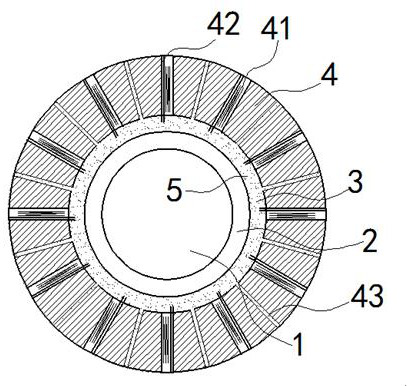

Vibration bionic insect-prevented cable

ActiveCN110428932AStable storageStable jobInsulated cablesAnimal repellantsEngineeringLow melting point

The invention relates to a vibration bionic insect-prevented cable. The vibration bionic insect-prevented cable includes a wire core and a protective layer wrapping an outer portion of the wire core.A liquid storage cavity sleeves the outer portion of the protective layer. A vibration glue with a low melting point is filled in the liquid storage cavity. A vibration layer wraps the outer portion of the liquid storage cavity. Vibration coils are arranged equidistantly on a circumferential wall of the vibration layer along an inner circumferential direction, and a ring surface of each vibrationcoil extends along a radial direction of the vibration layer. Magnetic vibration sheets which match with each vibration coil are installed in the circumferential wall of the vibration layer. Each magnetic vibration sheet is in contact with the vibration glue. A liquid guide hole is arranged on the vibration layer, and each liquid guide hole penetrates the vibration layer and is connected with theliquid storage cavity. The cable can effectively disperse snakes, rats, insects and ants around the cable and safe and stable operation of the buried cable is ensured.

Owner:SHENZHEN DONGJIAXIN CABLE&WIRE

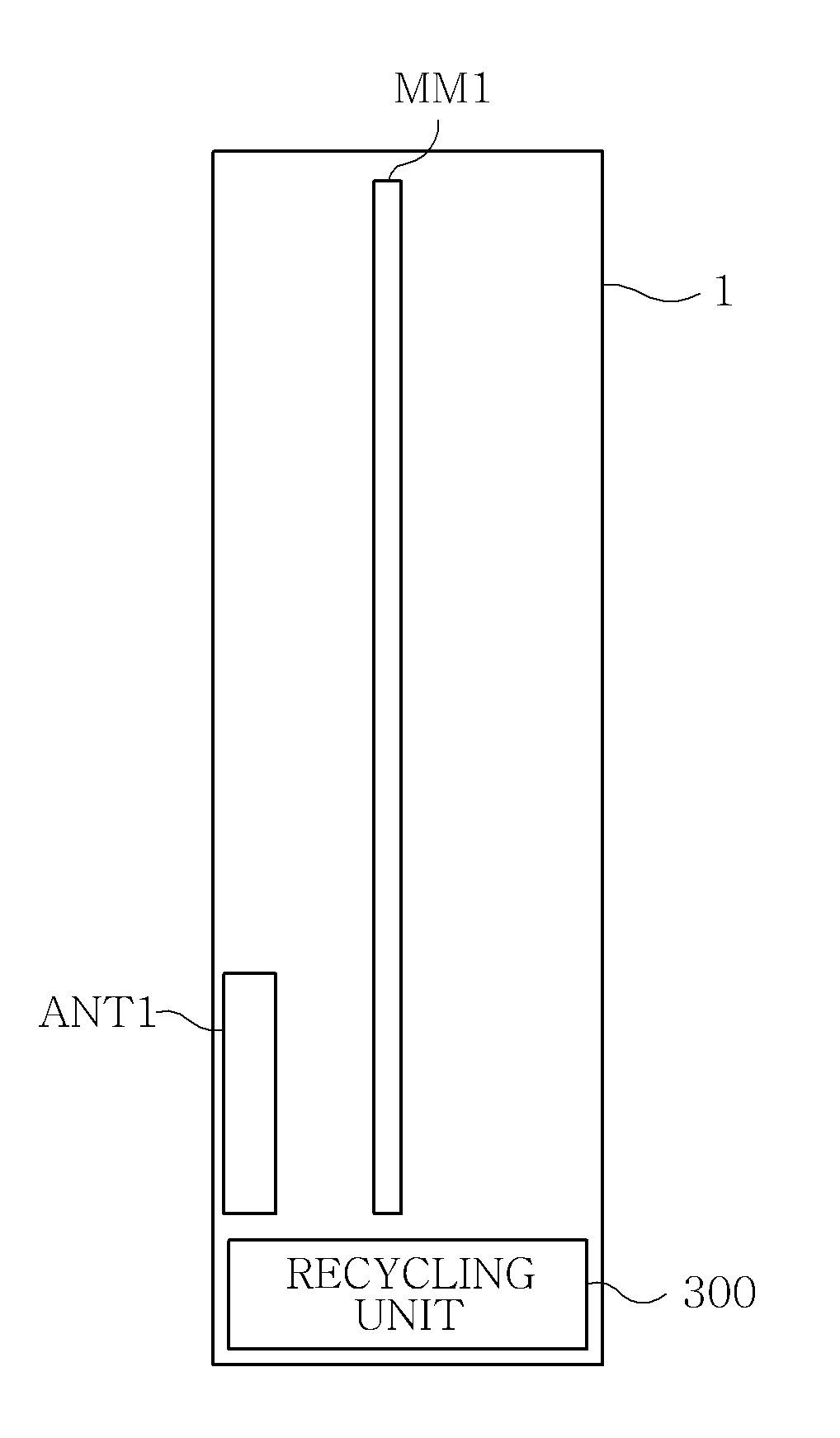

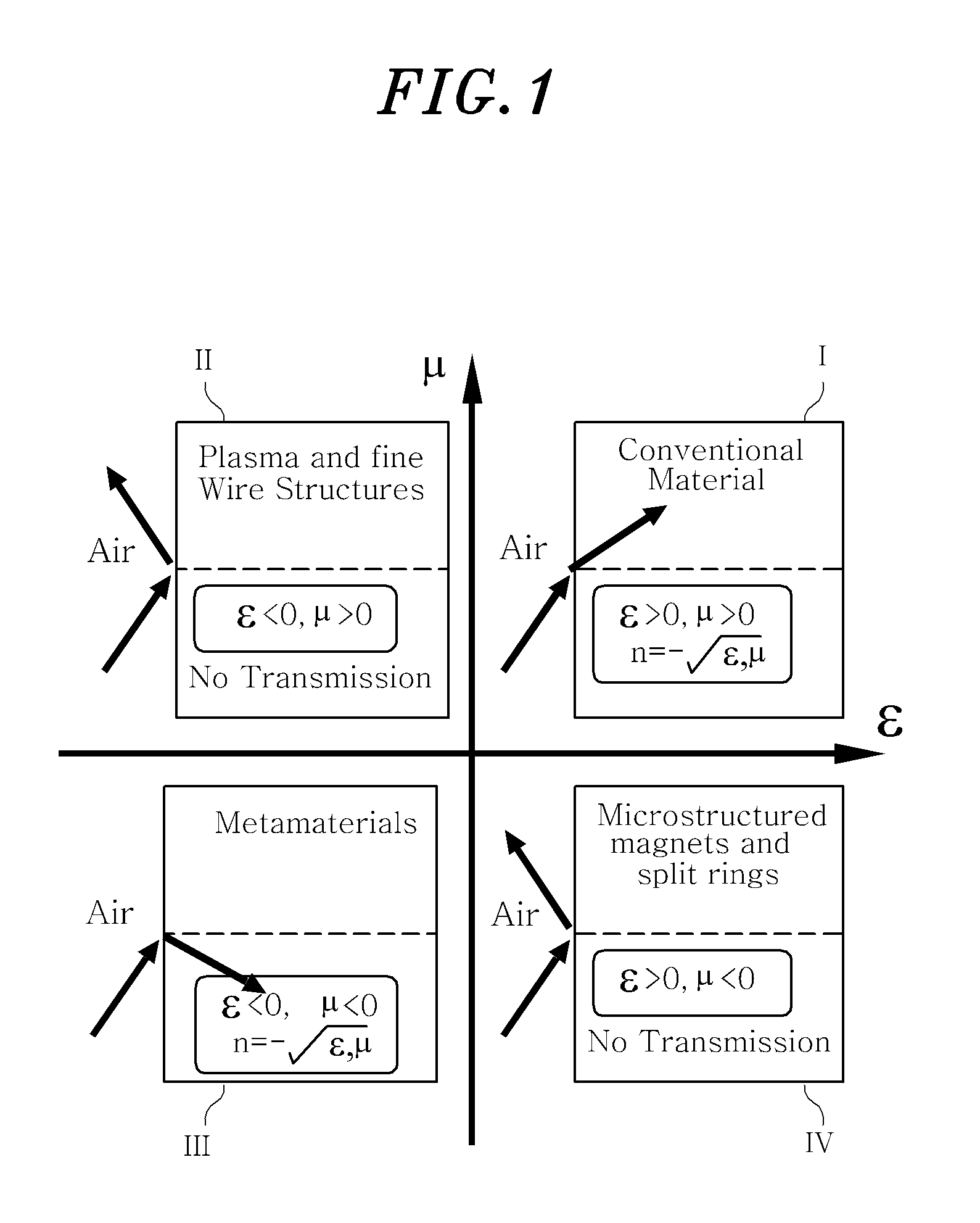

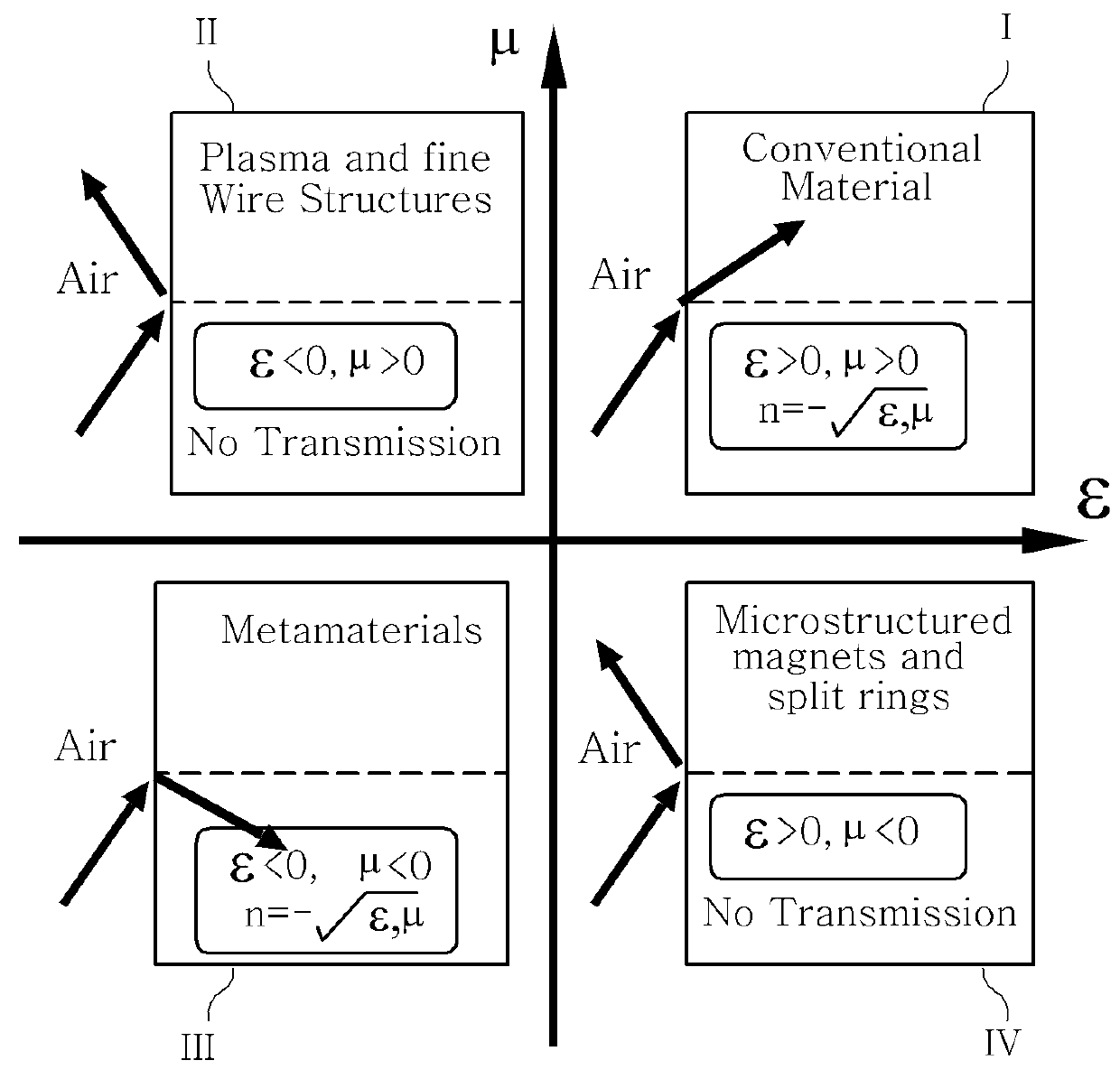

Terminal device having meta-structure

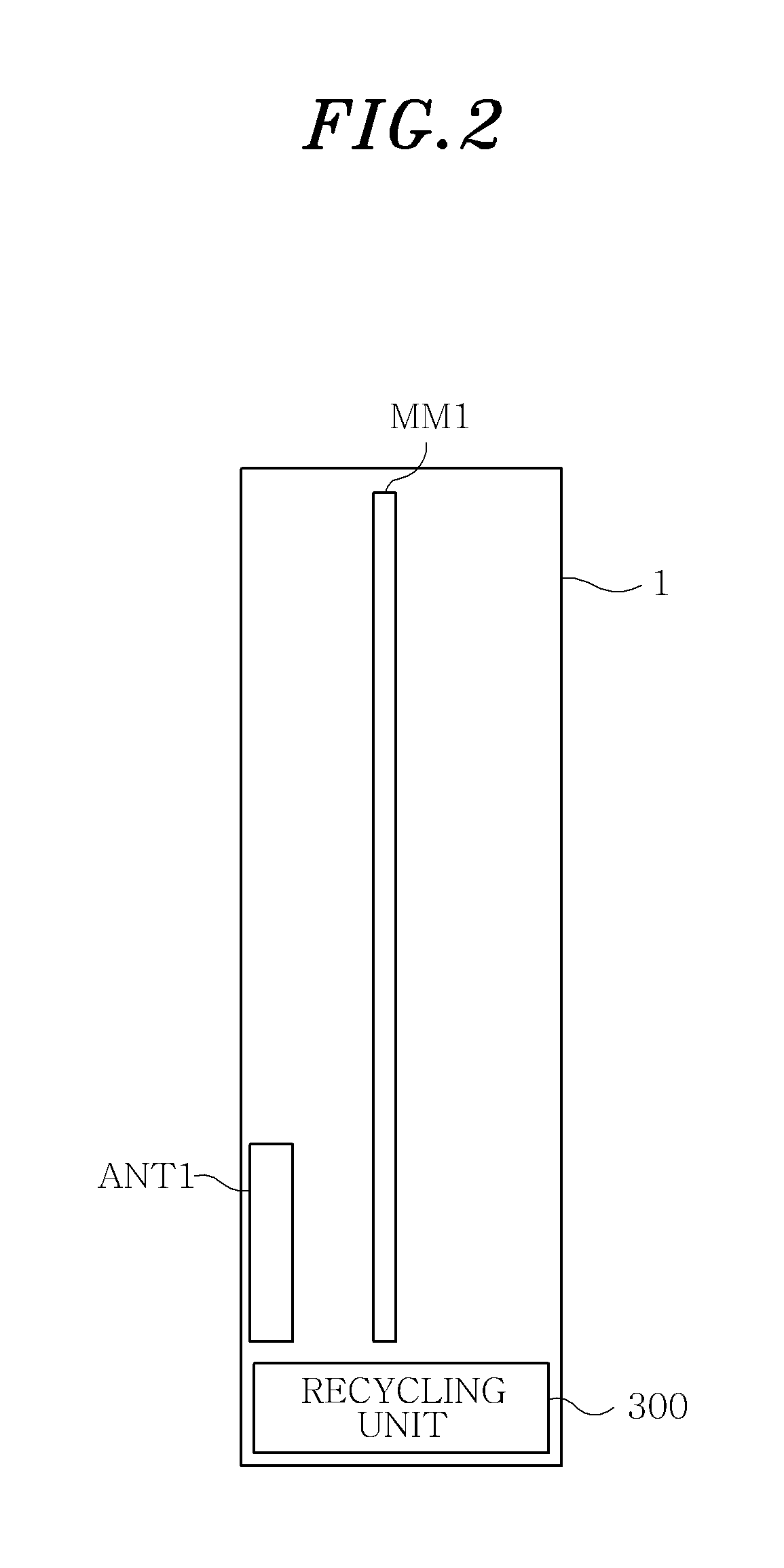

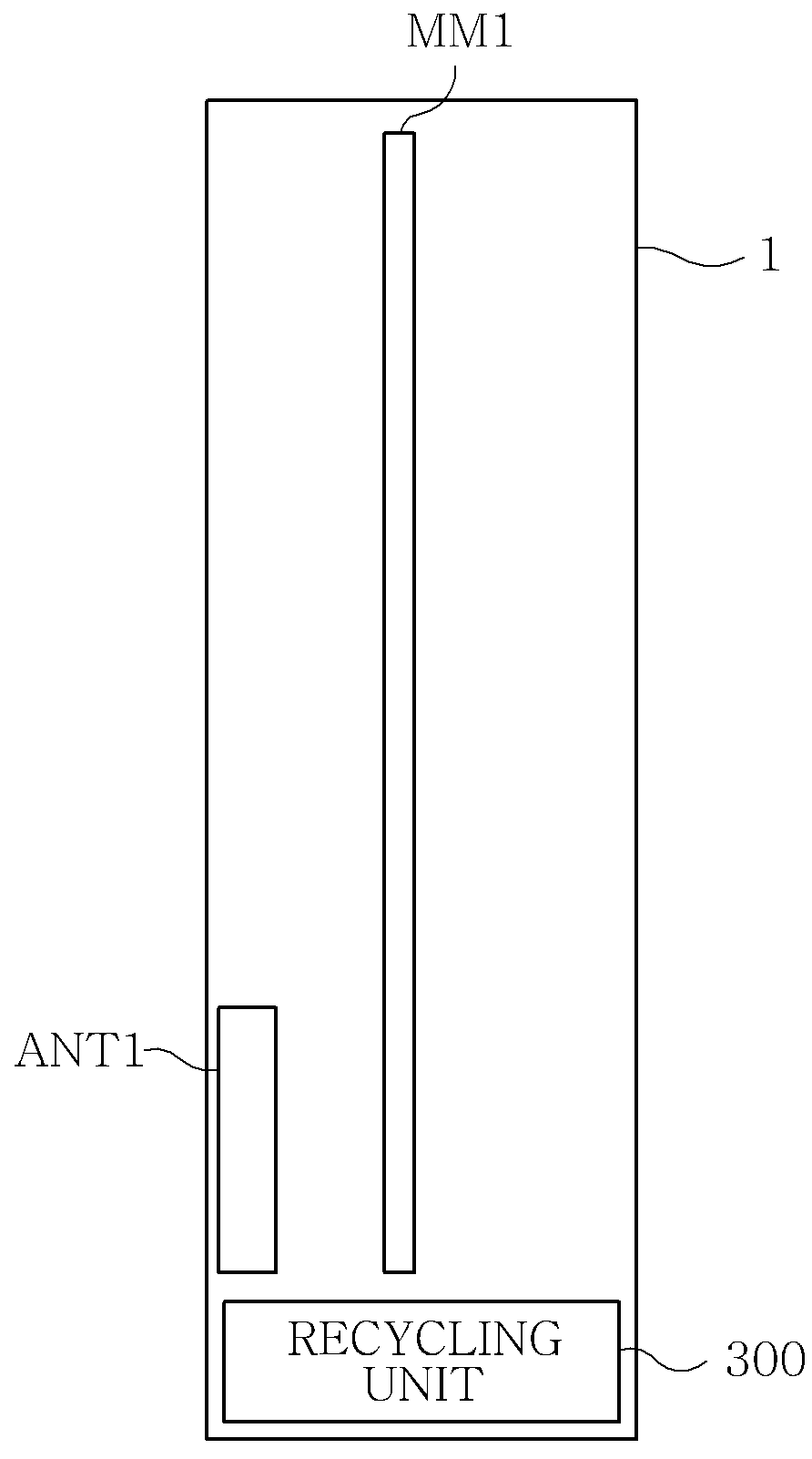

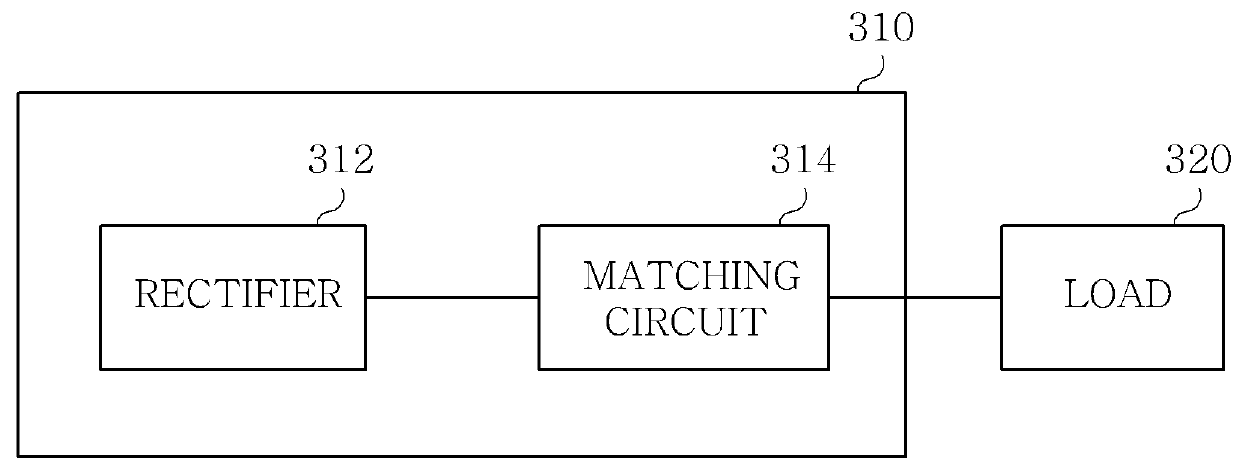

ActiveUS20140042971A1Improve electricity efficiencyReduce discharge phenomenonBatteries circuit arrangementsElectromagnetic wave systemEffective powerTerminal equipment

A terminal device includes a housing, a communication antenna installed in a first region in the housing and configured to transmit and receive electromagnetic waves, an agglomerative meta-structure installed in a second region spaced from the first region in the housing and configured to agglomerate the electromagnetic waves received from the communication antenna, and a recycling unit configured to convert the electromagnetic waves agglomerated by the agglomerative meta-structure to effective power.

Owner:FOUND OF SOONGSIL UNIV IND COOP

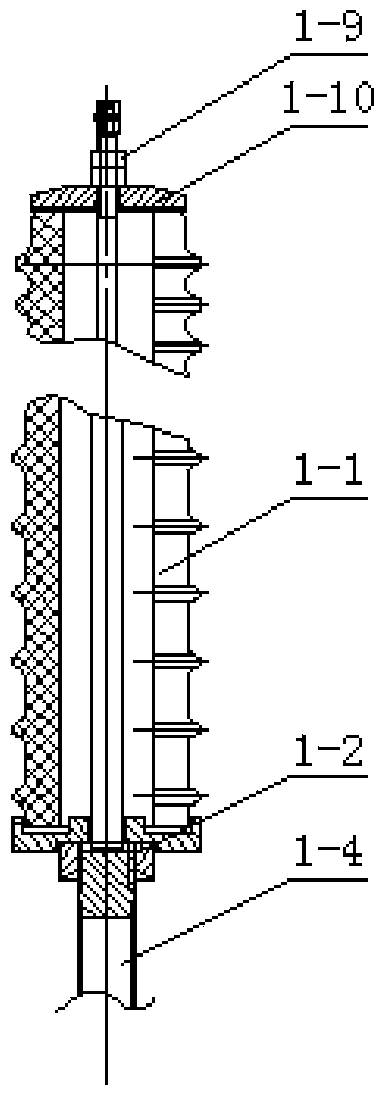

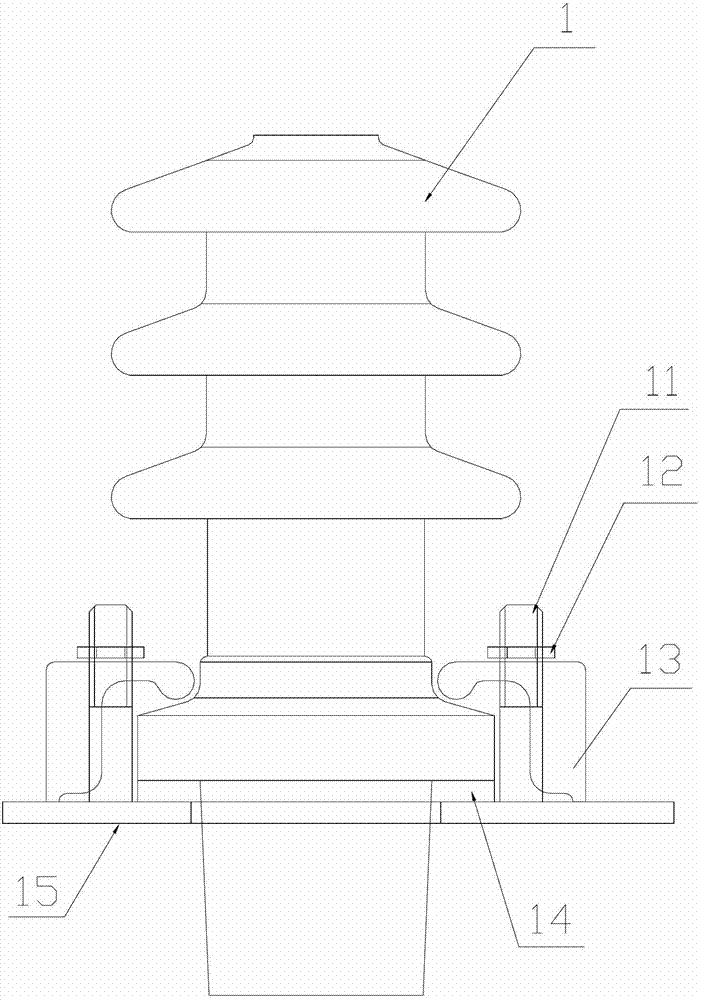

High-tension bushing of distribution transformer

InactiveCN103050249ASave man hoursImprove efficiencyTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureAgricultural engineeringHigh pressure

The invention discloses a high-tension bushing of a distribution transformer, and relates to the technical field of transformer equipment. The high-tension bushing comprises a cover plate and a high-tension bushing body, a bushing mounting hole is arranged in the middle of the cover plate, and the bottom end of the high-tension bushing body penetrates through the bushing mounting hole on the cover plate. The high-tension bushing is characterized in that a fixing plate is arranged on an area of the high-tension bushing body penetrating through the bushing mounting hole, two ends of the fixing plate are connected with the cover plate through fixing plate fastening bolts, and limit springs are arranged on two sides of the fixing plate contacting with the high-tension bushing body. Fixed welding of a stud on the cover plate is omitted, working hours are shortened, efficiency is improved, a creep distance is increased, discharge is decreased, a rubber sealing part is uniformly stressed, sealing effects are fine, oil does not easily leak, and the high-tension bushing is attractive in appearance and free of thermal stress deformation.

Owner:ANHUI SHENHONG TRANSFORMER

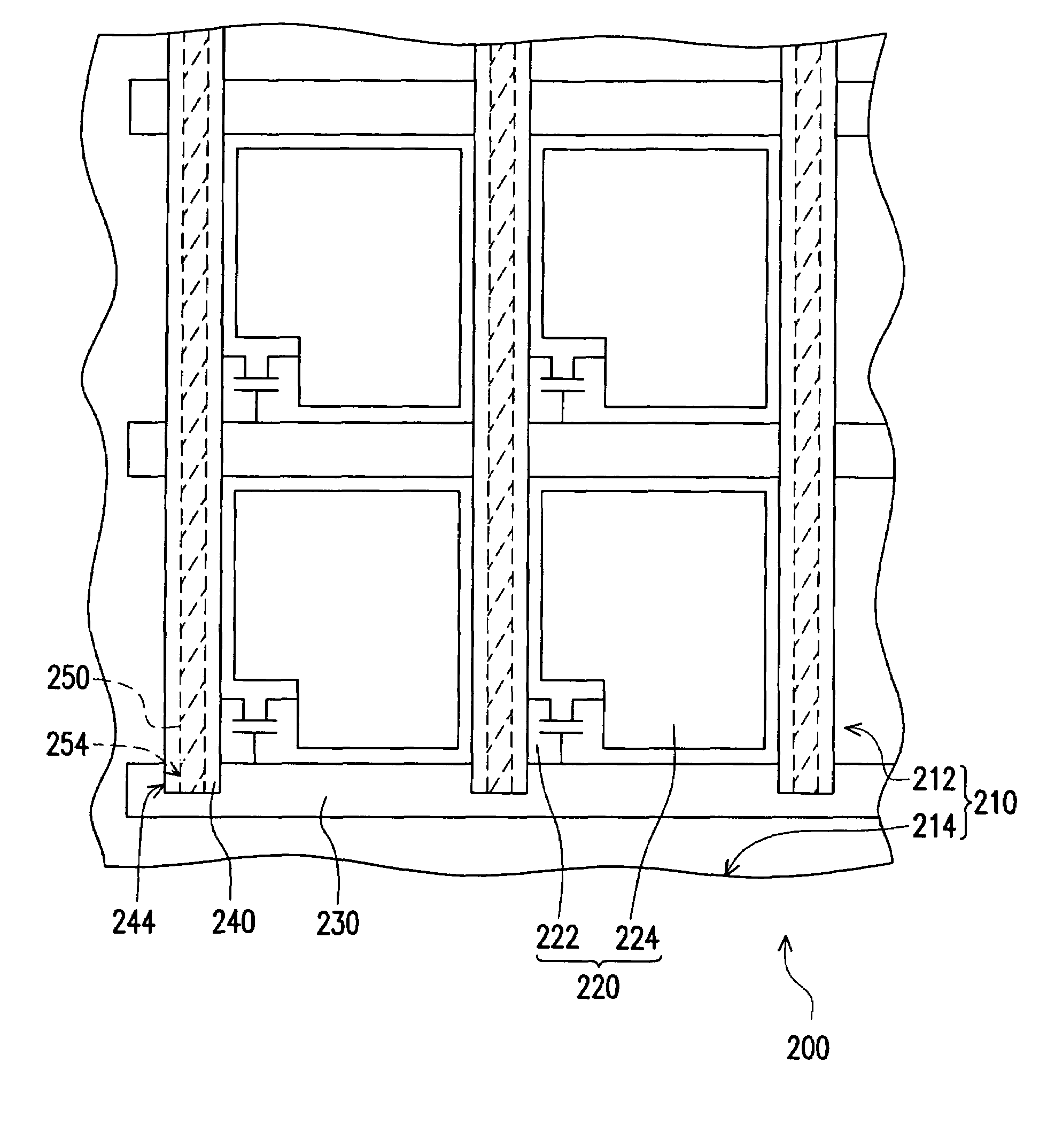

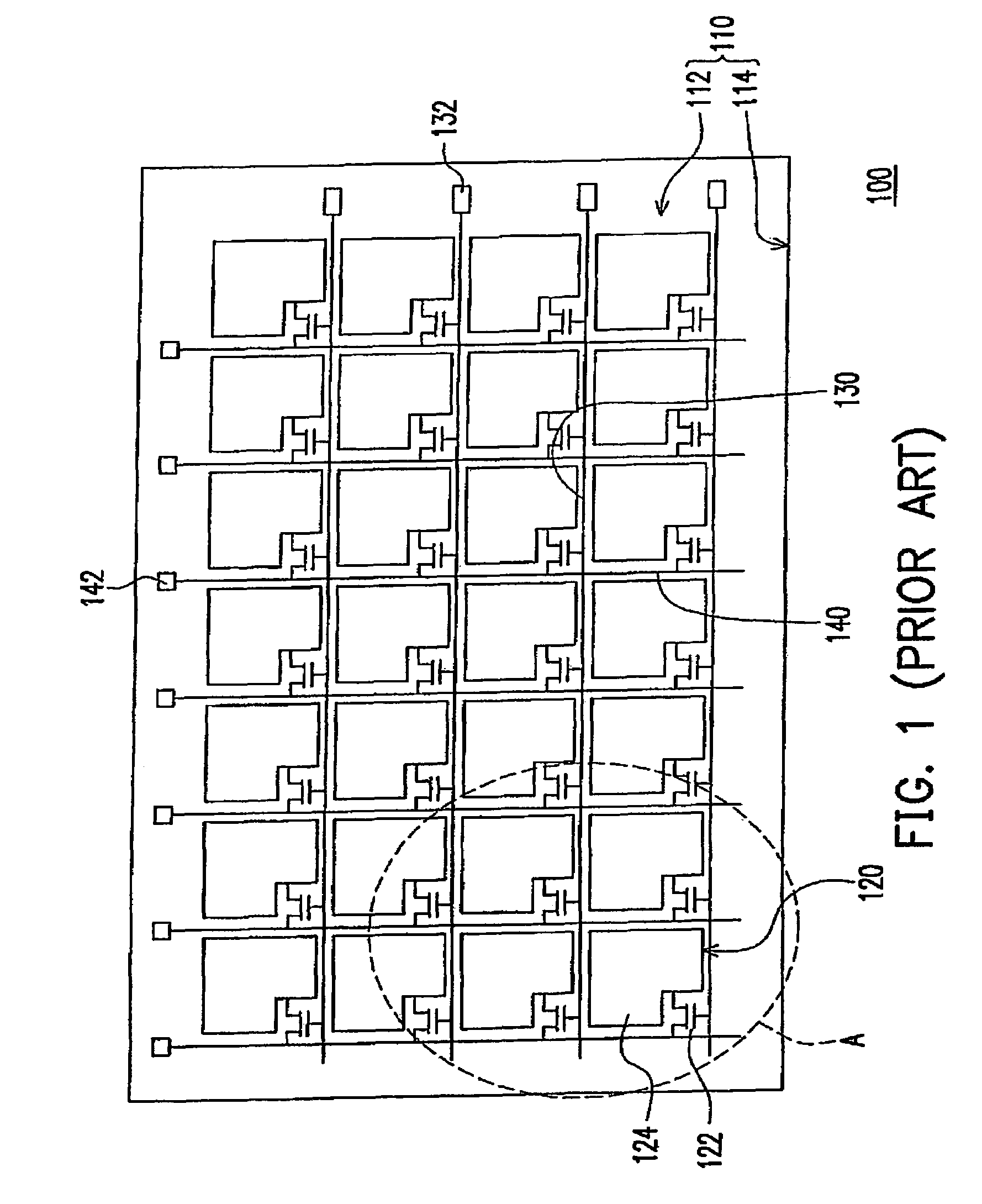

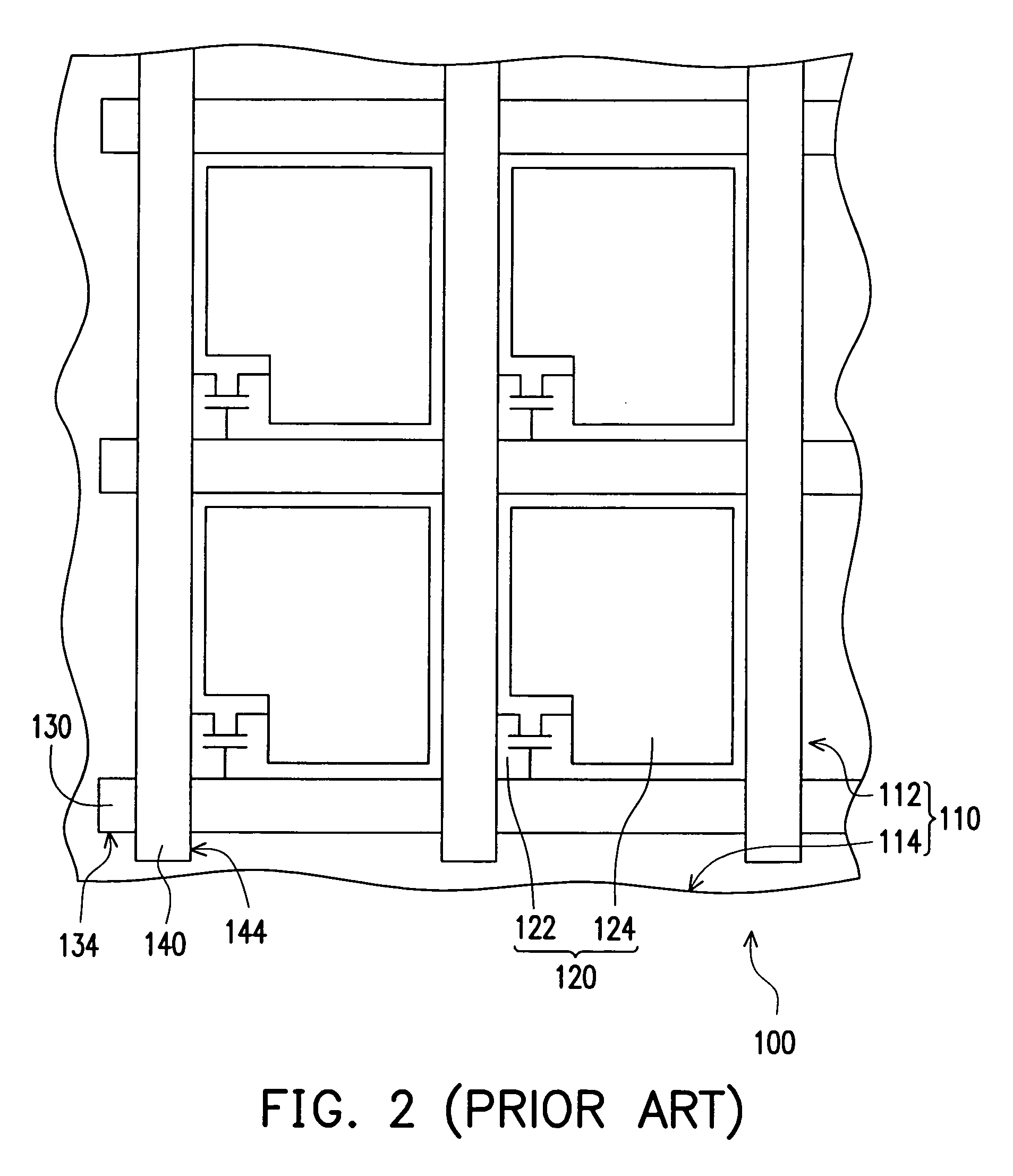

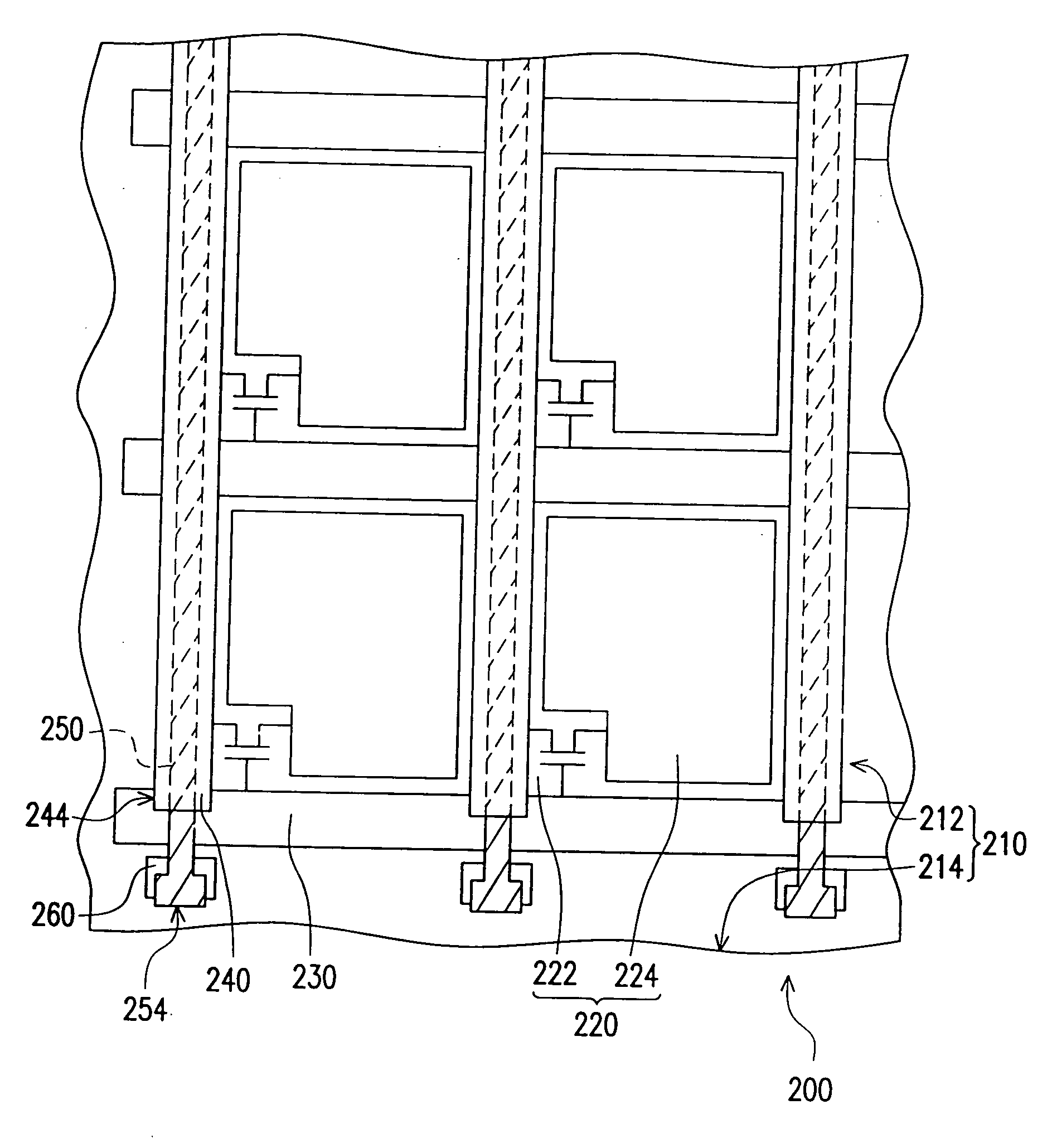

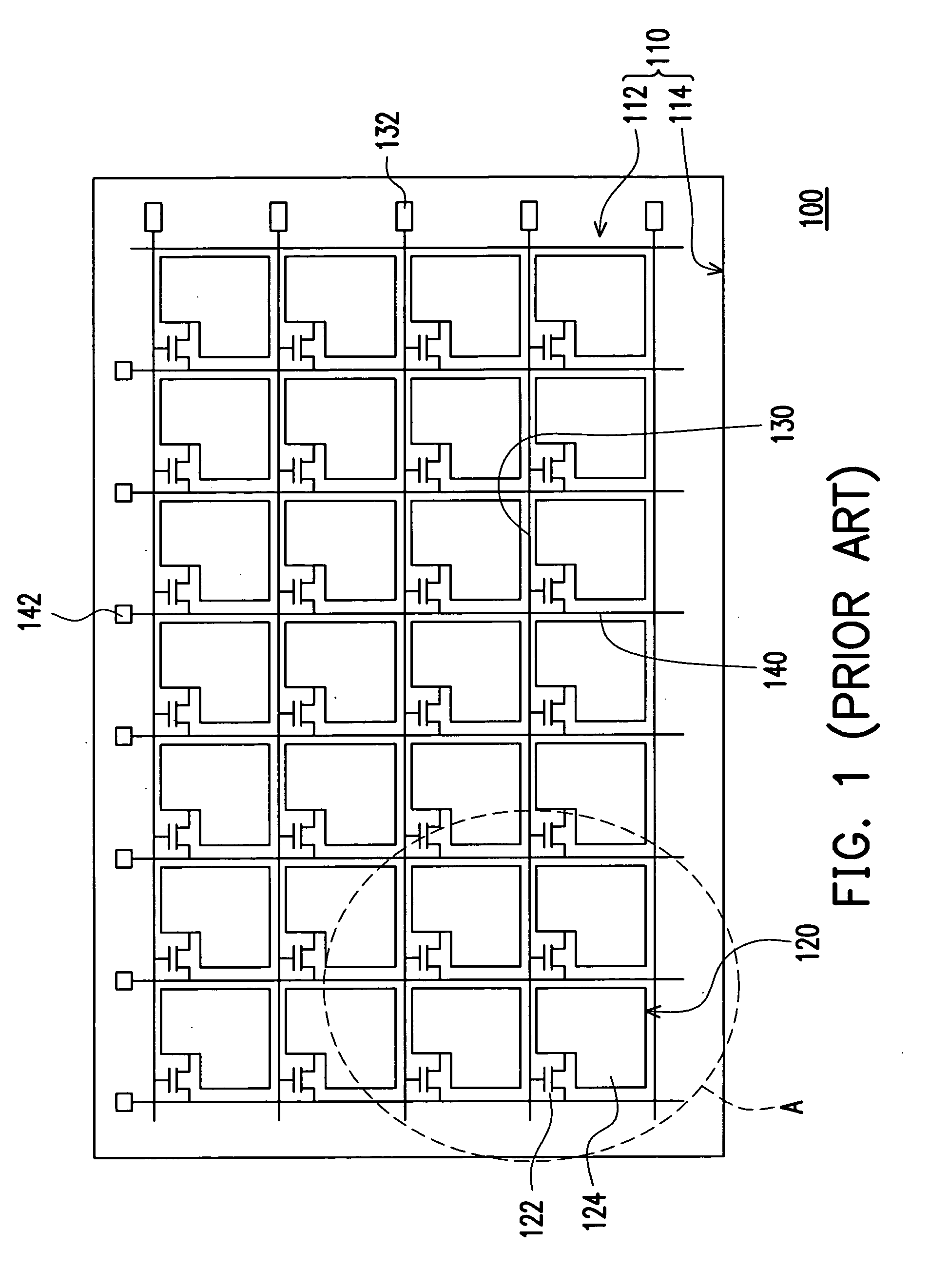

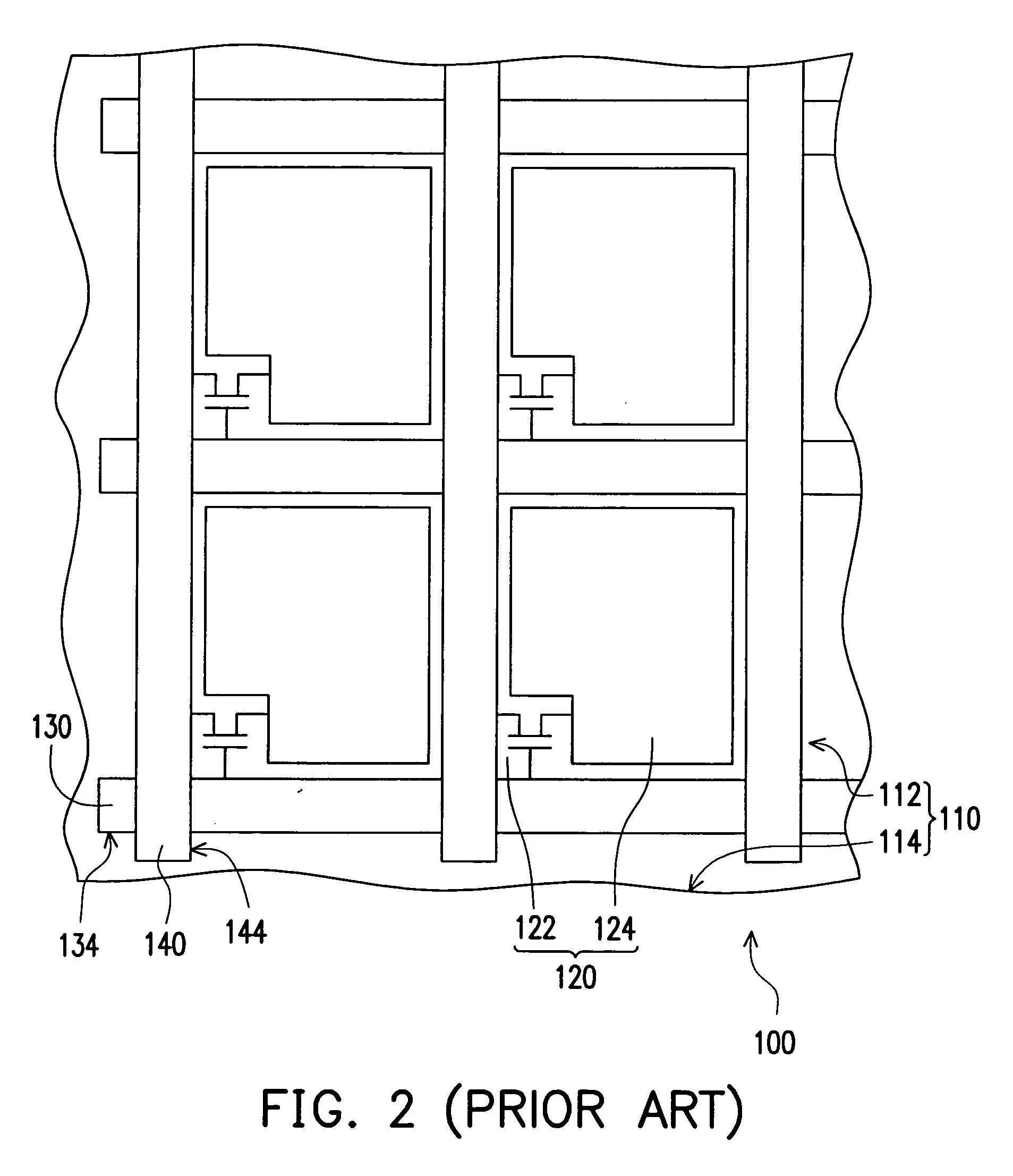

Thin film transistor array substrate having scan or data lines extending to peripheral area without exceeding respectively outmost data and scan lines for reducing electrostatic discharge damage

ActiveUS7489366B2Optimize layoutAvoid damageStatic indicating devicesSolid-state devicesScan lineEngineering

A thin film transistor (TFT) array substrate for reducing electrostatic discharge damage includes a substrate, a plurality of pixel units, scan lines and data lines. The substrate has a pixel area and a peripheral area adjacent to the pixel area. The pixel units are disposed in the pixel area. The scan lines and data lines are disposed in the pixel area of the substrate and electrically connected with the pixel units, wherein one end of each scan line extending to the peripheral area is a bonding pad for the scan line. One end of each data line extending to the peripheral area is a bonding pad for the data line. The other end of each data line extending to the peripheral area is an end part of the data line. Particularly, the end part of the data line does not exceed the outmost scan line.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Thin film transistor array substrate for reducing electrostatic discharge damage

ActiveUS20070131989A1Reducing electrostatic discharge damageOptimize layoutStatic indicating devicesSolid-state devicesScan lineEngineering

A thin film transistor (TFT) array substrate for reducing electrostatic discharge damage includes a substrate, a plurality of pixel units, scan lines and data lines. The substrate has a pixel area and a peripheral area adjacent to the pixel area. The pixel units are disposed in the pixel area. The scan lines and data lines are disposed in the pixel area of the substrate and electrically connected with the pixel units, wherein one end of each scan line extending to the peripheral area is a bonding pad for the scan line. One end of each data line extending to the peripheral area is a bonding pad for the data line. The other end of each data line extending to the peripheral area is an end part of the data line. Particularly, the end part of the data line does not exceed the outmost scan line.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

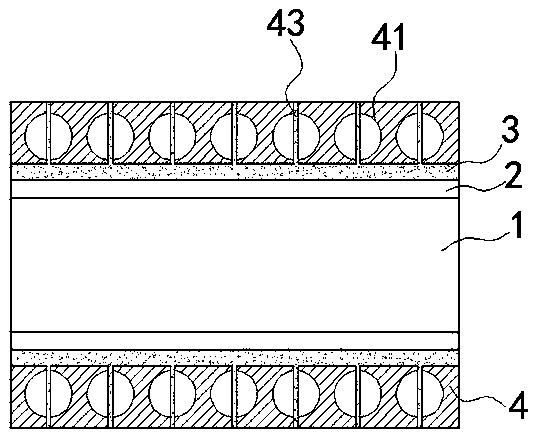

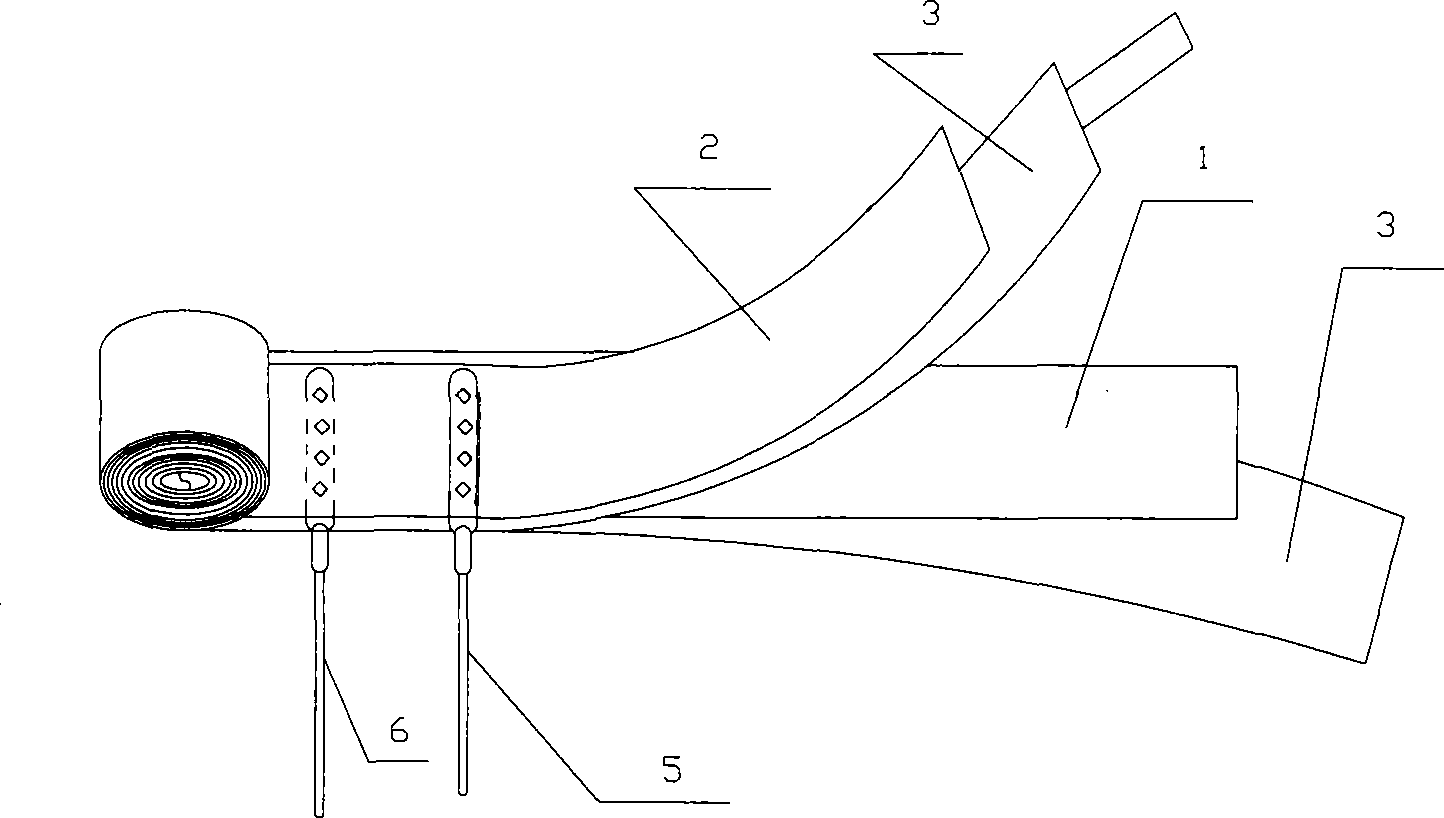

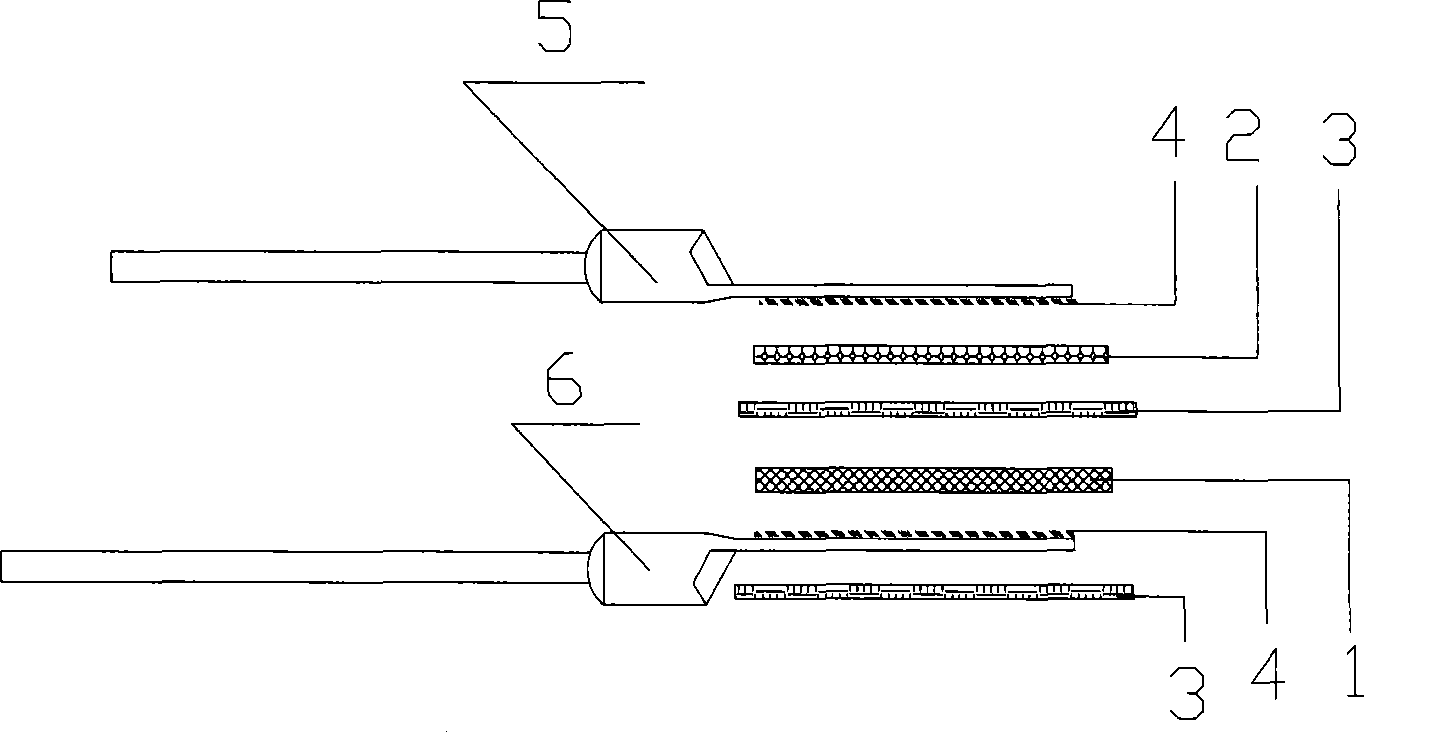

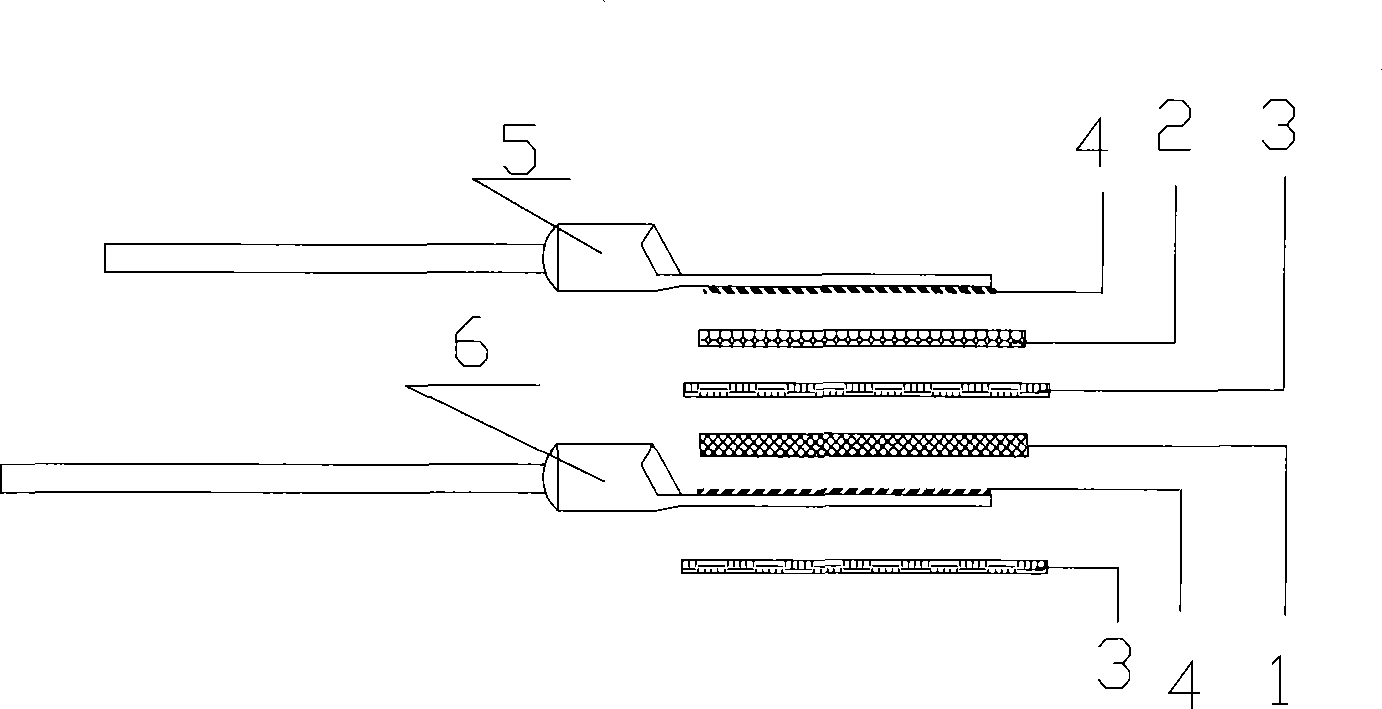

Manufacturing process of aluminum electrolytic capacitor for reducing point discharge phenomenon

ActiveCN101369491AReduce discharge phenomenonExtend product lifeCapacitor terminalsAluminum electrolytic capacitorMaterials science

The invention relates to a process for manufacturing an aluminum electrolytic capacitor to reduce point discharge phenomenon, which is characterized in that, firstly a positive guide needle and a negative needle select surfaces, a tongue part of a positive guide needle is provided on the positive electrode aluminum foil, one surface with burr is contacted with a foil surface of the positive electrode aluminum foil, a tongue part of a negative guide needle is provided under the negative electrode aluminum foil, one surface with burr is contacted with a foil surface of the negative electrode aluminum foil, a layer of electrolytic papers are respectively arranged between the positive electrode aluminum foil and the negative electrode aluminum foil and under the positive electrode aluminum foil, a surface without burr of the positive guide needle is contacted with the electrolytic papers, the positive guide needle and the negative guide needle are back to back, burrs of the two guide needles are face to face, the aluminum electrolytic capacitor is prepared according to the common process. The invention has advantages that the guide pin aluminum tongue burr can not transpierce the electrolytic papers and can reduce the burr point discharge phenomenon, thereby extending life of the product and greatly reducing the product middle-period invalidation phenomenon.

Owner:SHANGHAI YONGMING ELECTRONICS

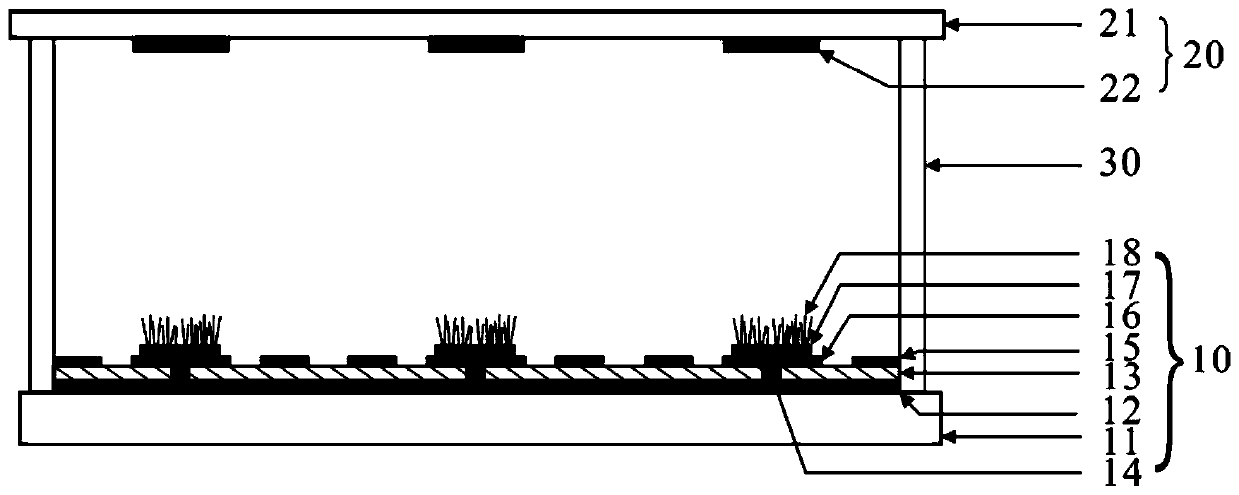

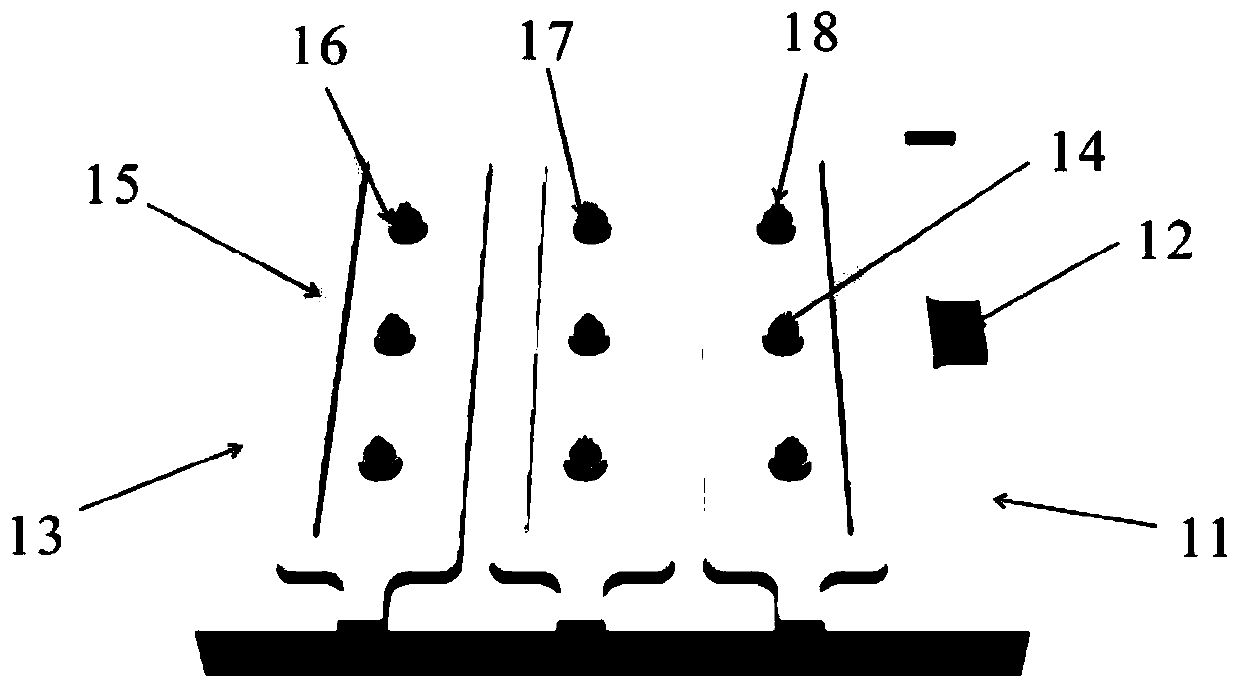

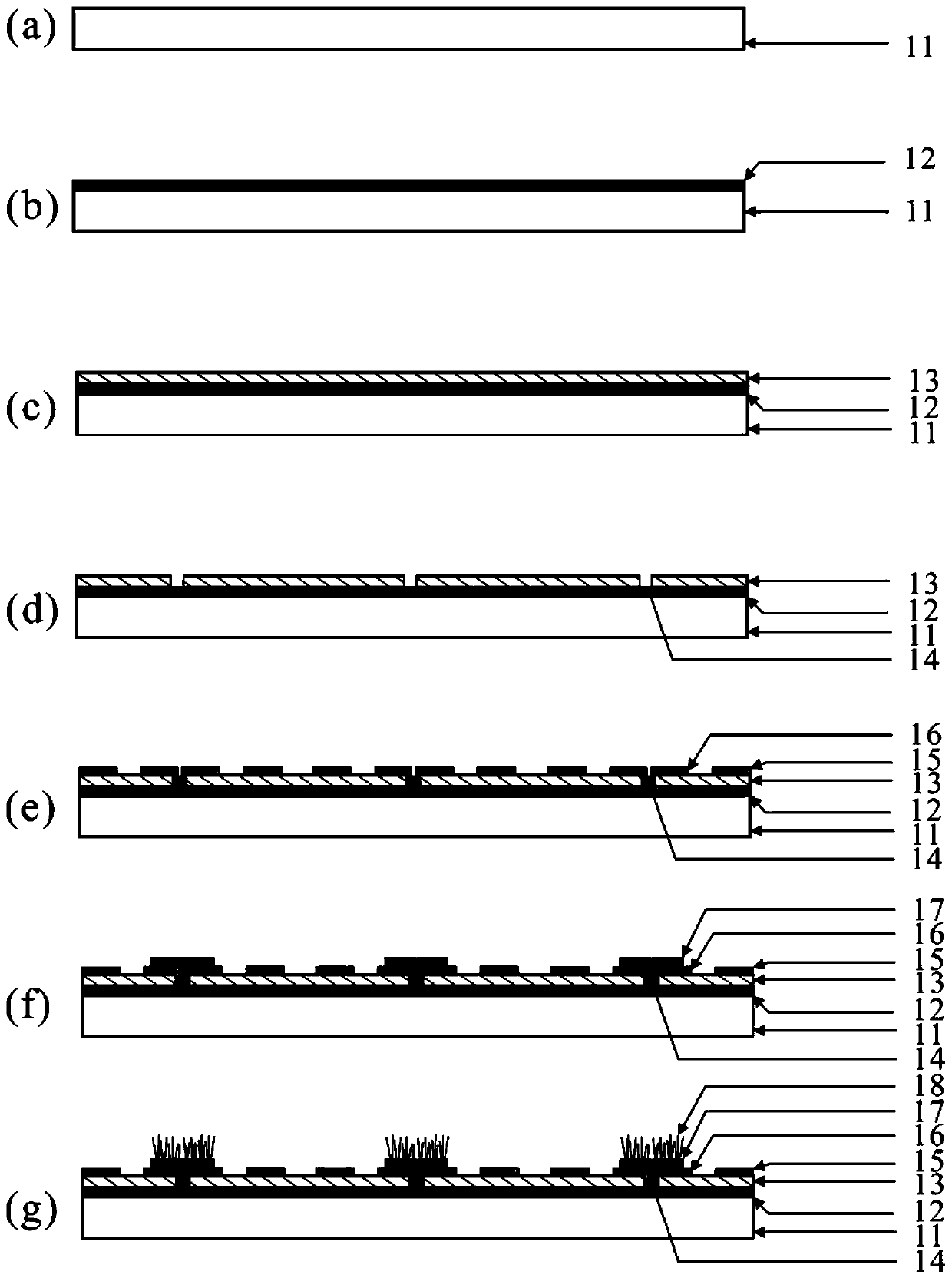

Grid-anode interdigital grid-controlled panel X-ray source and preparation method thereof

ActiveCN111063597ARemove Motion ArtifactsReduce radiation doseX-ray tube electrodesCold cathode manufacturePhysicsAnode voltage

The invention discloses a grid-anode interdigital grid-controlled panel X-ray source, which comprises a cathode substrate, an anode substrate and a high-voltage insulation isolator, wherein the cathode substrate and the anode substrate are oppositely arranged in parallel, and the high-voltage insulation isolator is arranged between the cathode substrate and the anode substrate to isolate the cathode substrate from the anode substrate. The invention further discloses a preparation method of the grid-anode interdigital grid-controlled panel X-ray source, which comprises the steps of manufacturing a cathode substrate, manufacturing an anode substrate and assembling the cathode substrate and the anode substrate. The interdigital arrangement between the grid and the anode can effectively reducethe edge electric field of the top grid electrode, reduce the discharge problem and improve the working stability of the device, so that the anode voltage is further improved while control by the grid realized. Meanwhile, the structure can realize the row addressing function through the control of different grids.

Owner:SUN YAT SEN UNIV

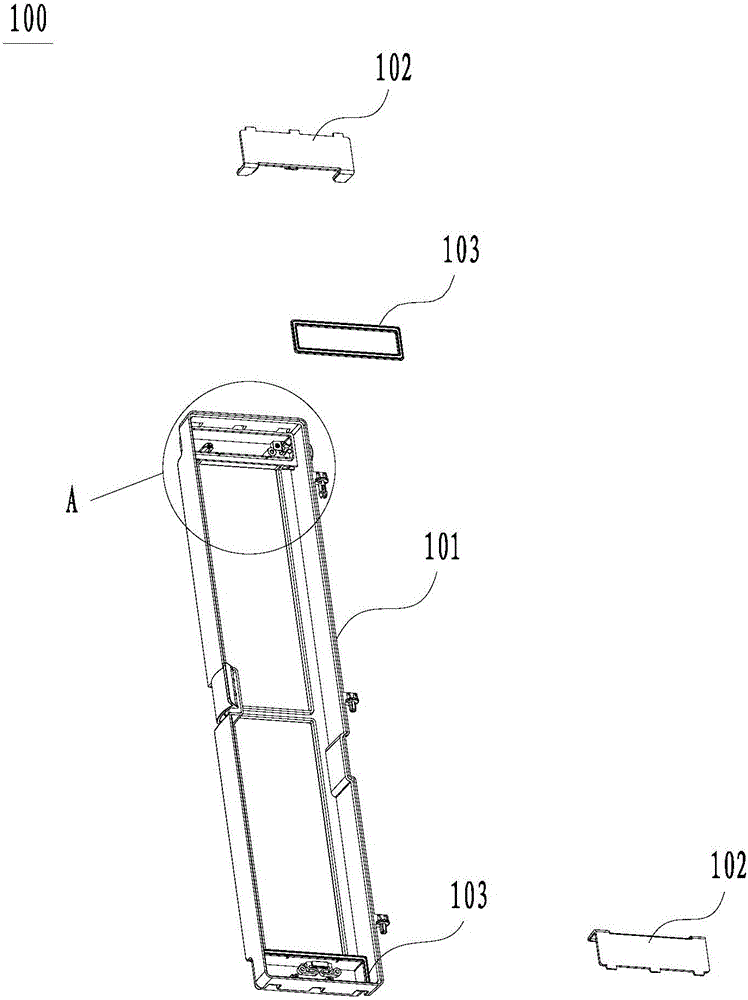

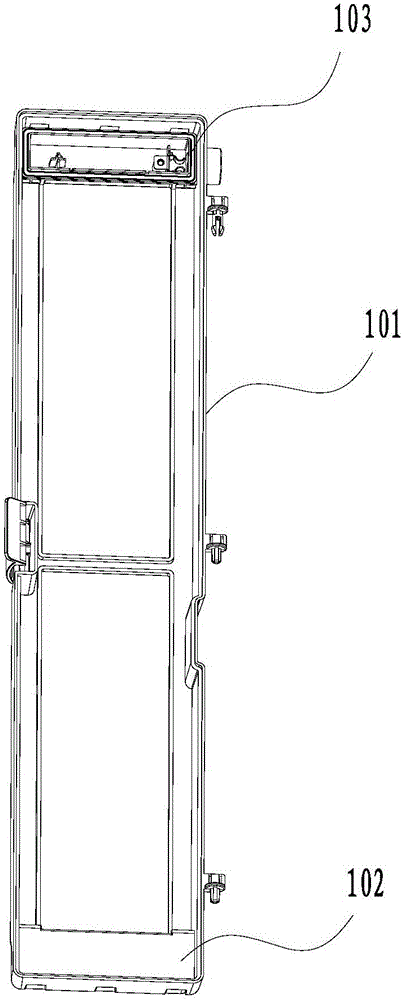

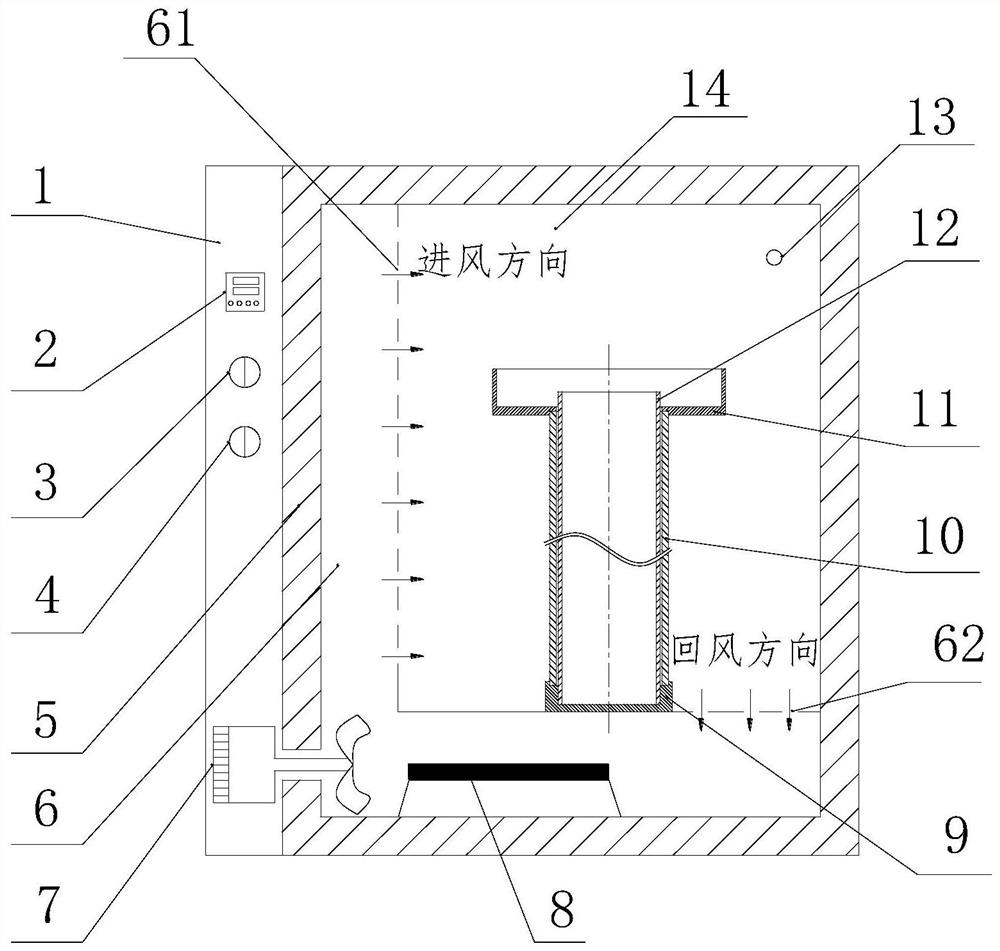

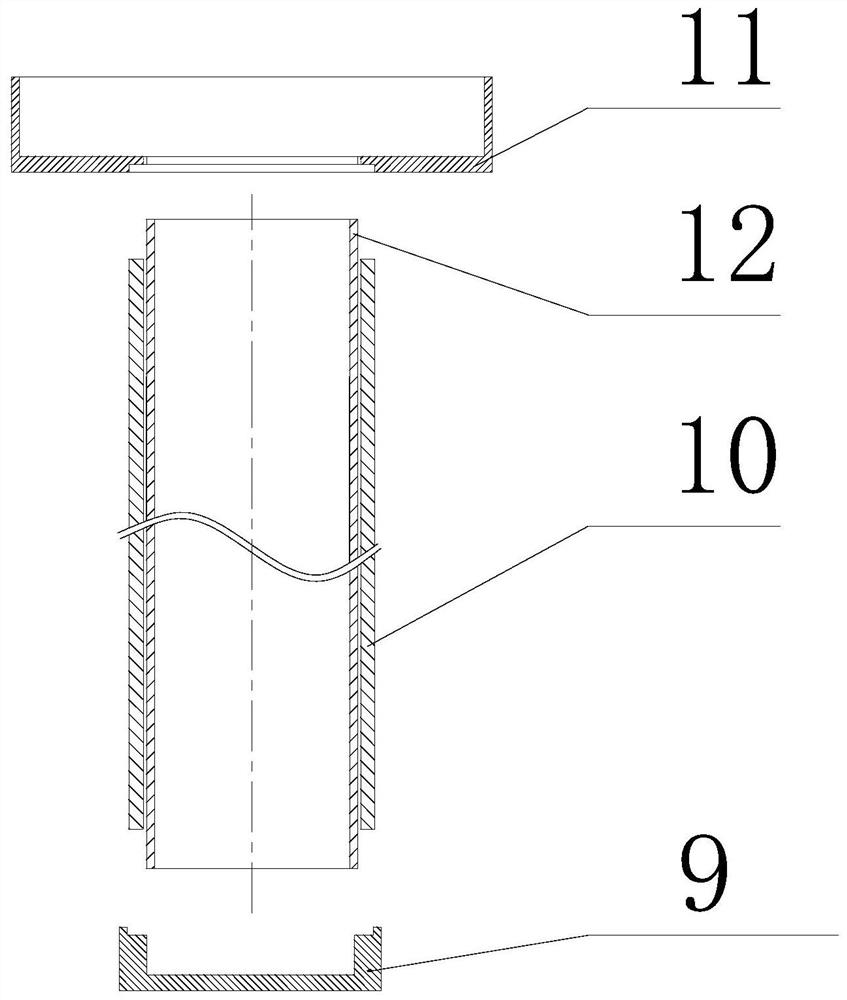

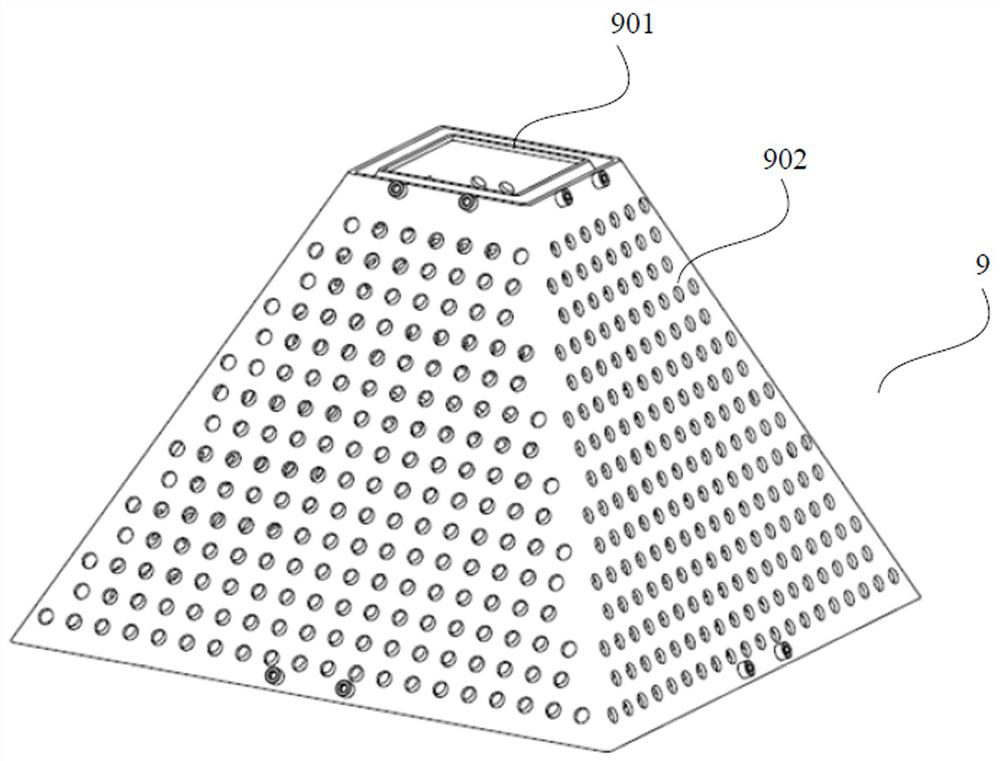

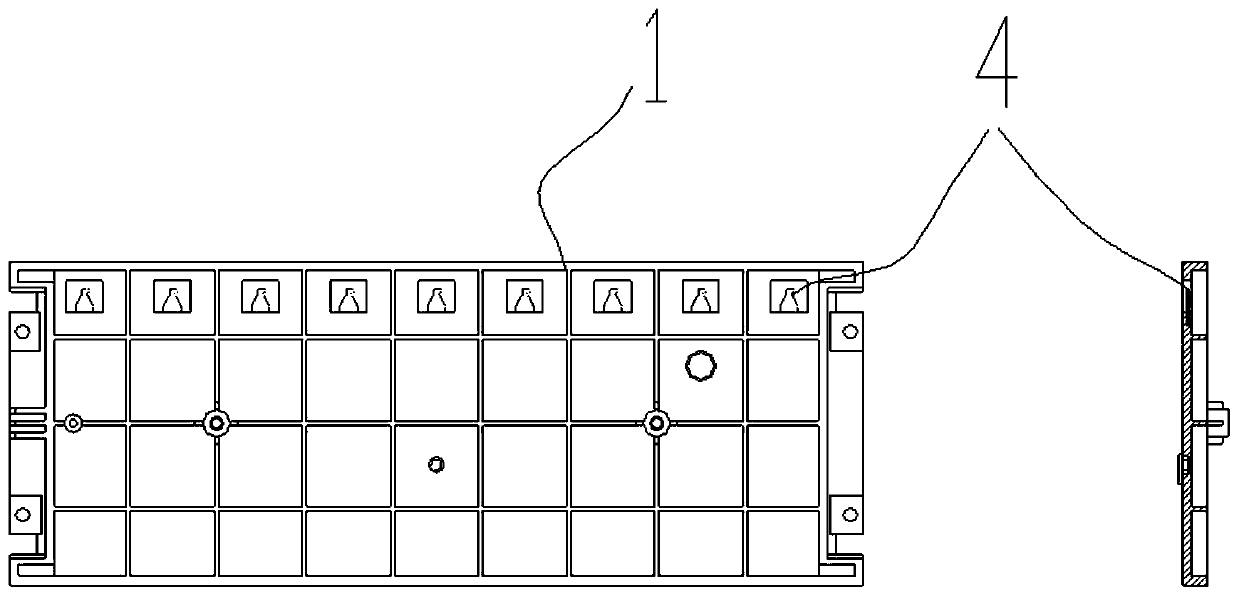

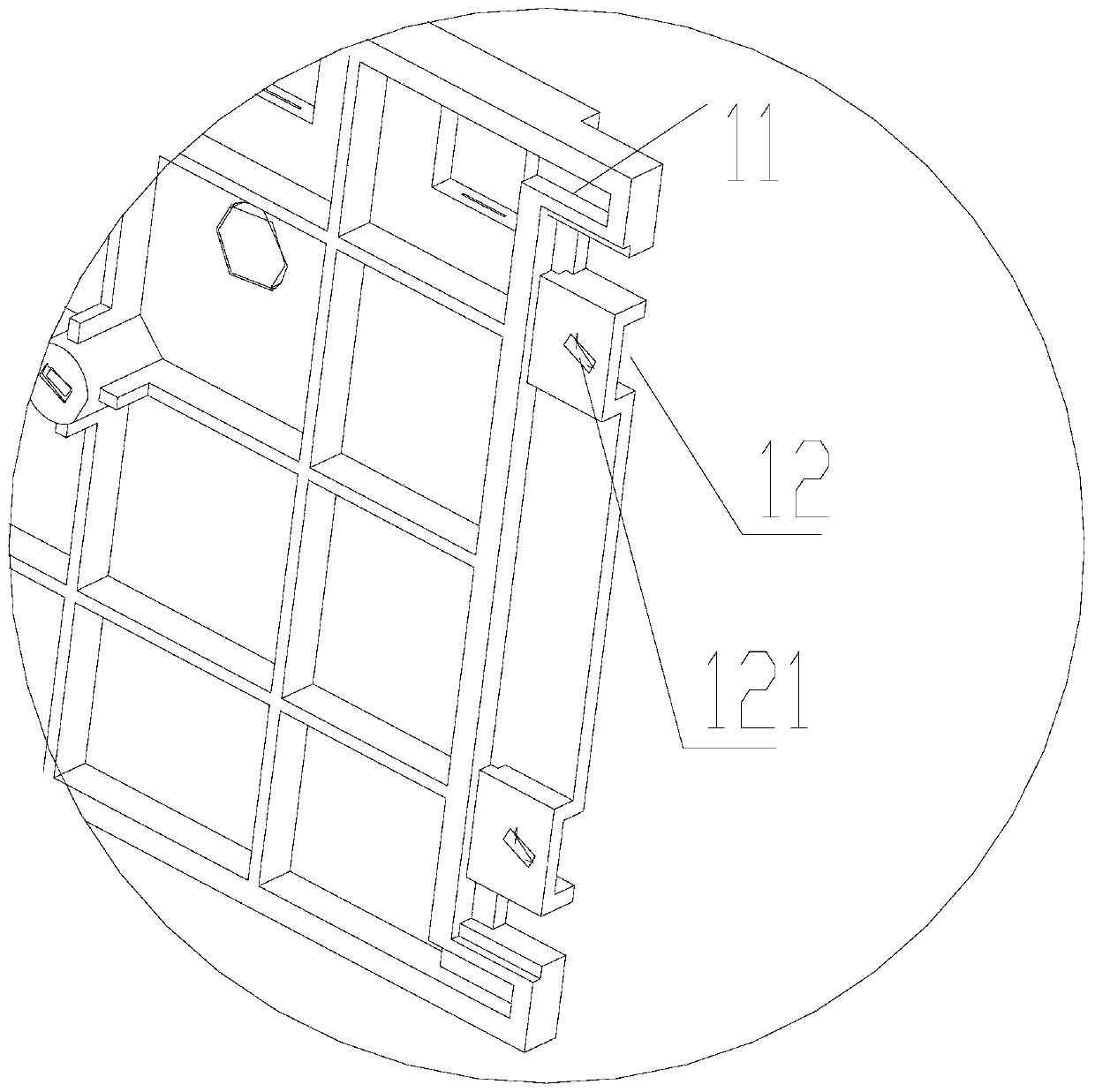

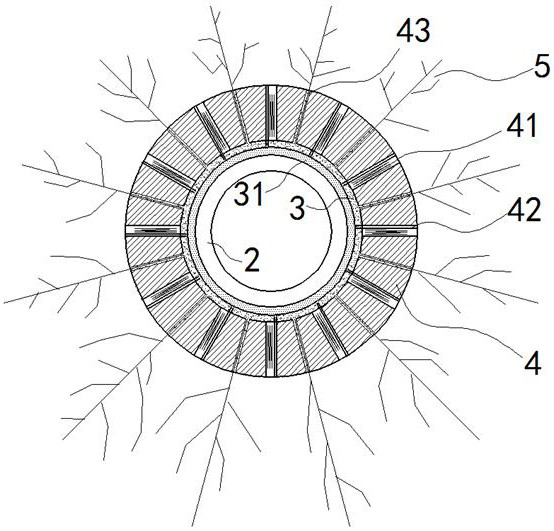

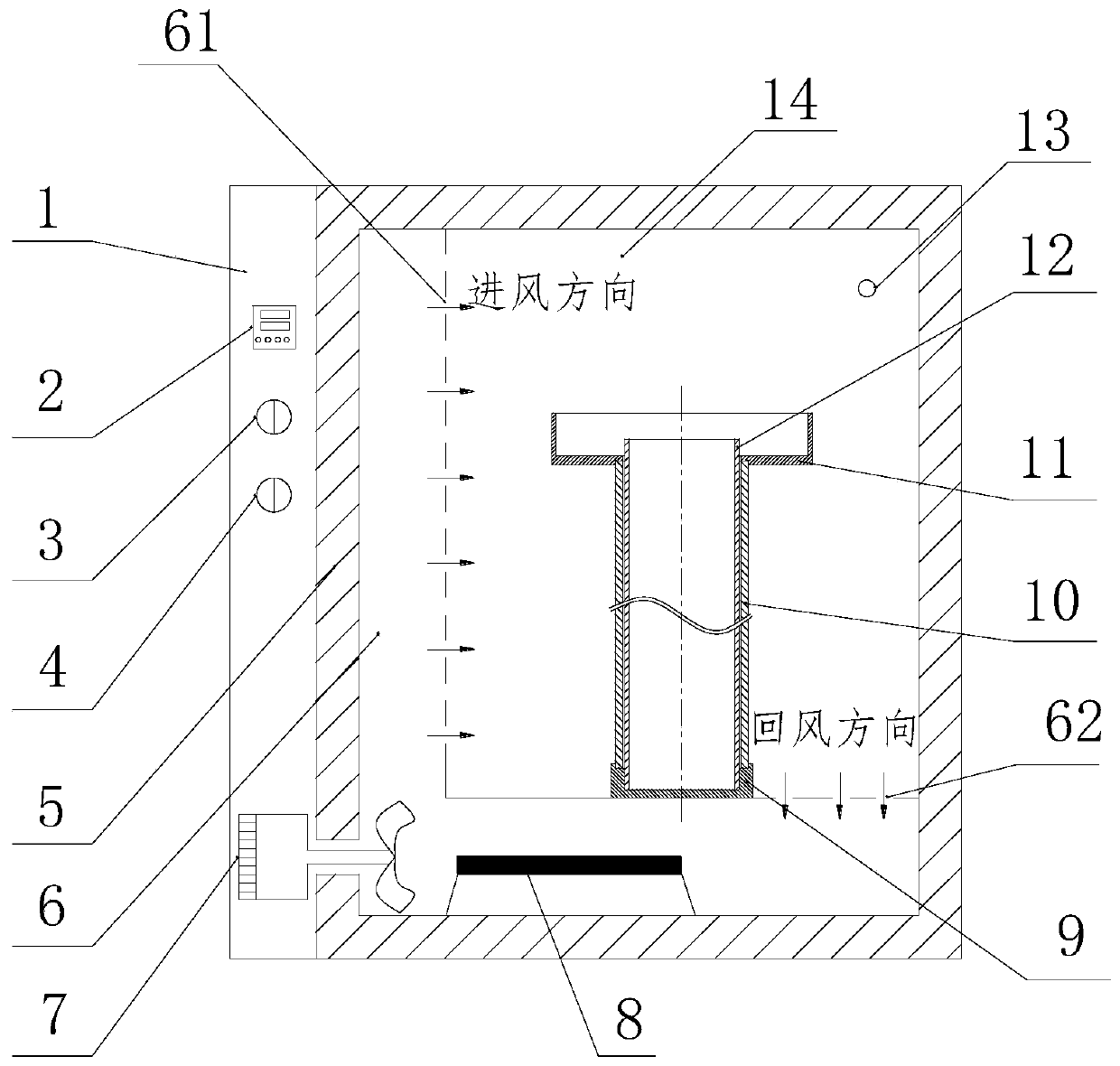

Tungsten filament assembly of air purifier and air purifier

ActiveCN105880021AGuaranteed purification efficiencyAvoid enteringElectrode carrying meansEngineeringAir purifier

The invention provides a tungsten filament assembly of an air purifier. The tungsten filament assembly of the air purifier comprises a tungsten filament support, a cover plate, a tungsten filament and a sealing piece. The tungsten filament support is provided with a tungsten filament fixing end. The cover plate is arranged at the tungsten filament fixing end in a covering mode. The tungsten filament is arranged at the tungsten filament fixing end and covered with the cover plate. The sealing piece is arranged between the tungsten filament fixing end and the cover plate. The invention further relates to the air purifier. According to the tungsten filament assembly of the air purifier and the air purifier, a hole position of the tungsten filament assembly is sealed, so that dust is effectively prevented from entering the tungsten filament assembly, and accordingly the probability that discharging is caused due to the fact that dust is excessively accumulated in the tungsten filament assembly is lowered; and the air purification efficiency is guaranteed, and the generation quantity of ozone is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

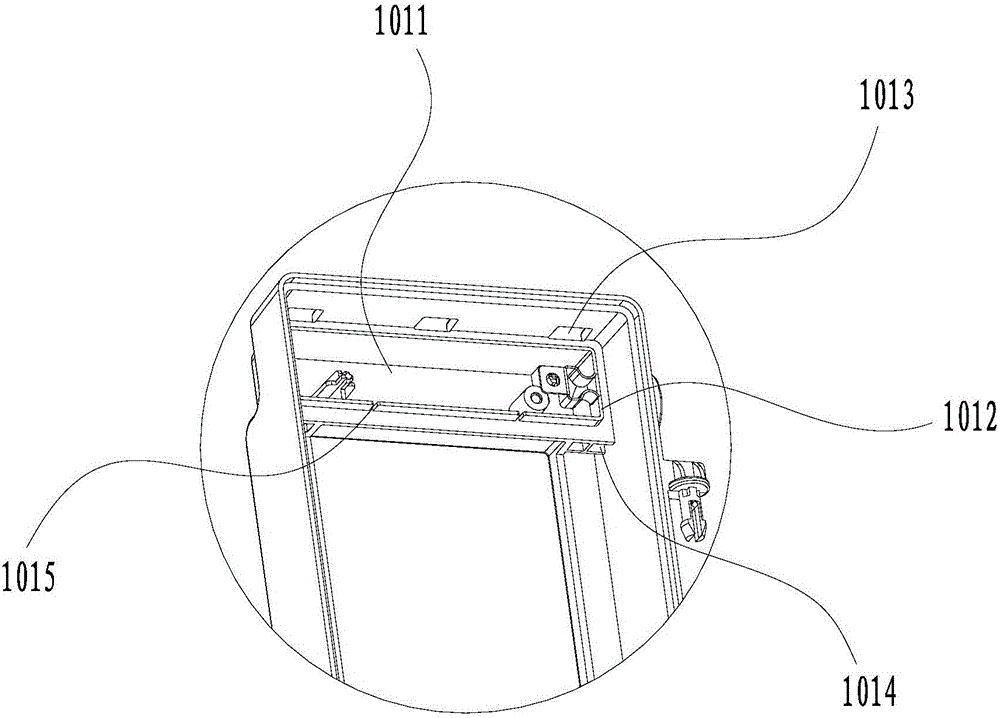

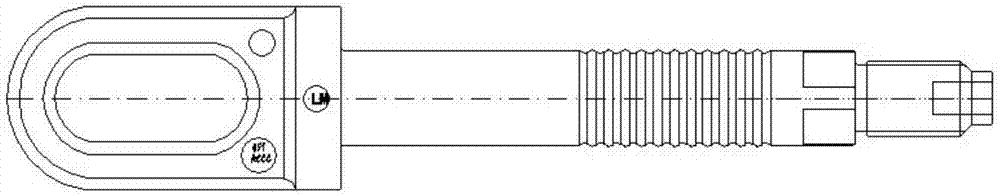

Strain clamp of composite-core all-aluminum conductor expansion terminal

InactiveCN107394728AIncrease frictionImprove gripAdjusting/maintaining mechanical tensionPower cableEngineering

The invention, which belongs to the technical field of a power cable clamping device, in particular relates to a strain clamp of a composite-core all-aluminum conductor expansion terminal. The strain clamp comprises a spinning type steel anchor, a strain casing pipe, a tensioned clamp core, a strain clamp sleeve, a liner pipe, a wire core, and a drainage plate. Two-level threads with different external diameters are arranged at the front end of the spinning type steel anchor, wherein the external diameter of the first-level thread is larger than that of the second-level thread; and a support head is formed at the front end of the second-level thread. The strain casing pipe is a penetrating tubular pipe with same diameters; and the front end of the tubular pipe has an arc shape in a convergence manner. The external diameter of the liner pipe matches the internal diameter of the strain casing pipe. A crimping point is arranged at the arc convergence part of the front end of the strain casing pipe. Circumferential lines are arranged at the outer surface of the liner pipe. Because the circumferential lines are arranged at the outer surface of the liner pipe, the friction force between the liner pipe and the strain casing pipe is increased. After the spinning type steel anchor, the strain clamp sleeve, the tensioned clamp core, and the strain casing pipe are assembled, the crimping point is extruded to fix the liner pipe, so that the wire is fixed.

Owner:徐州宇飞电力科技有限公司

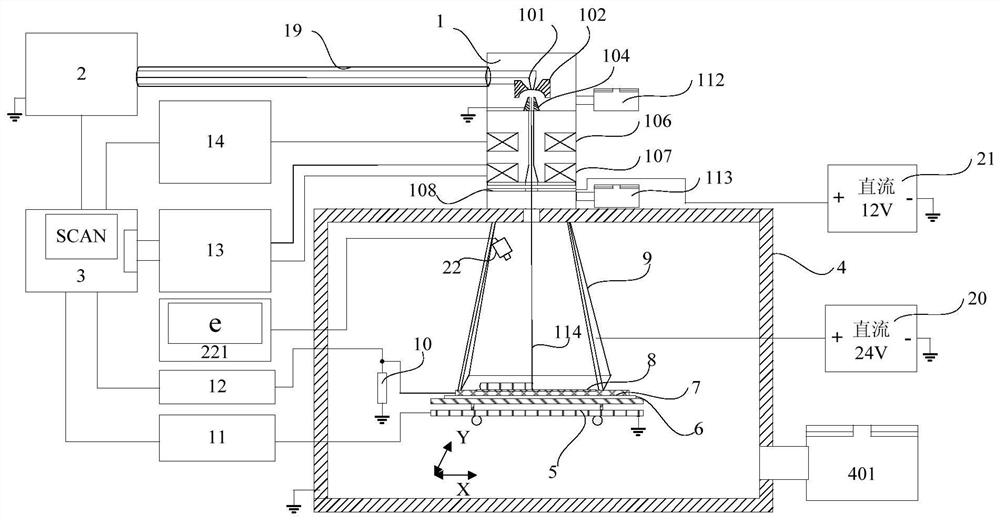

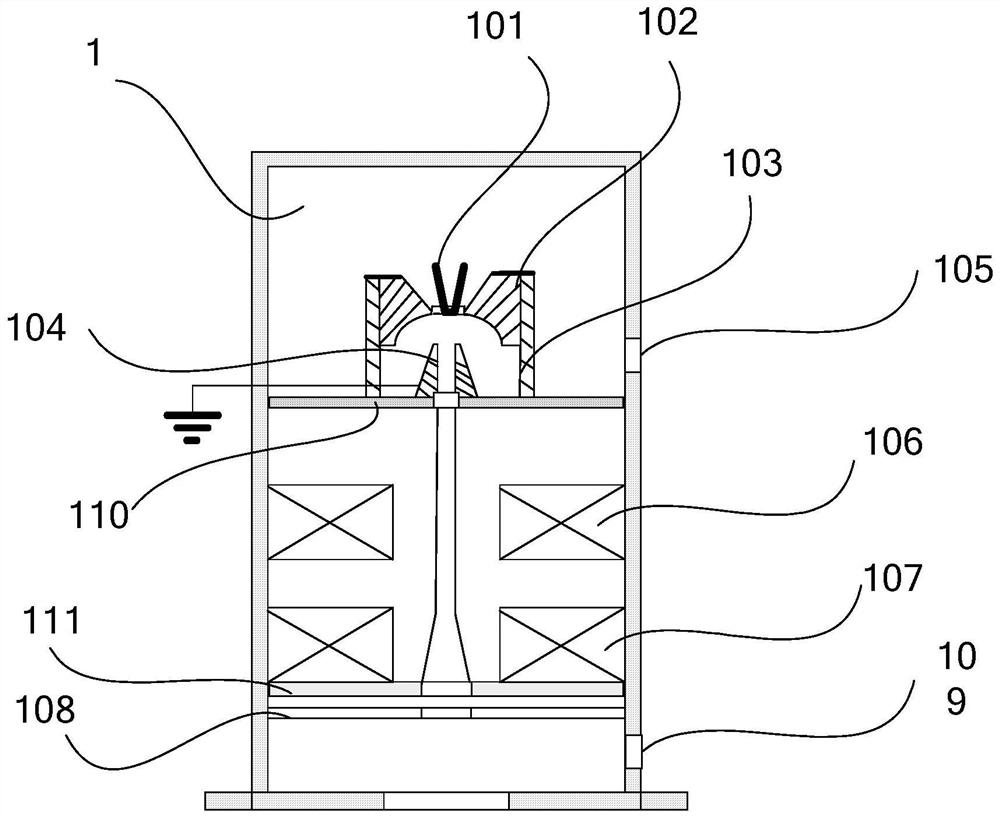

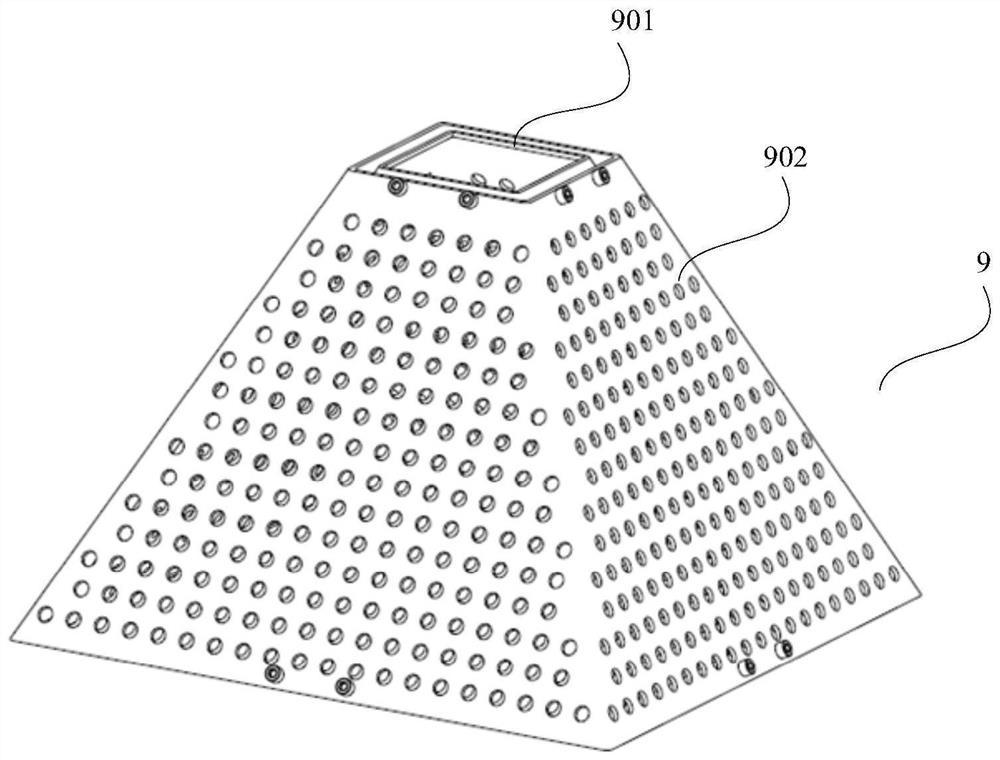

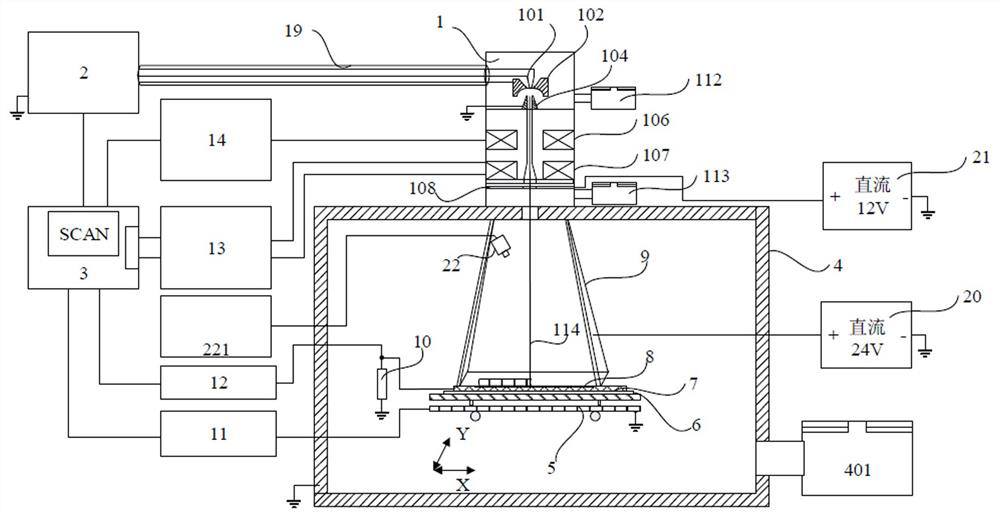

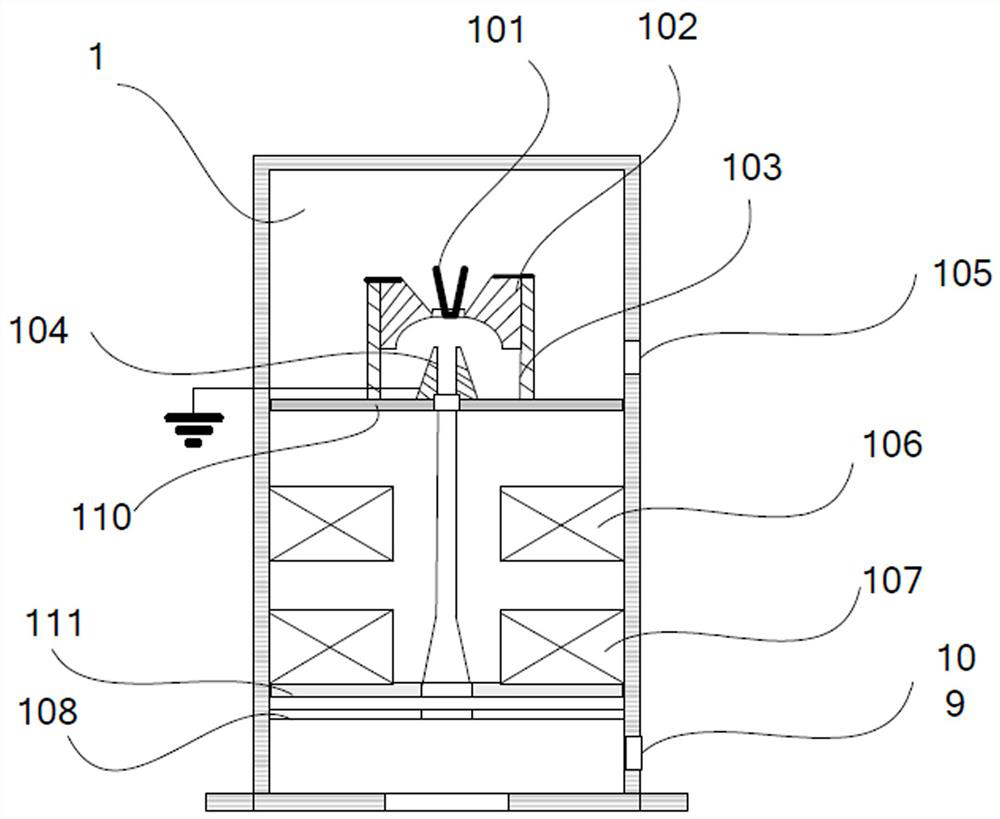

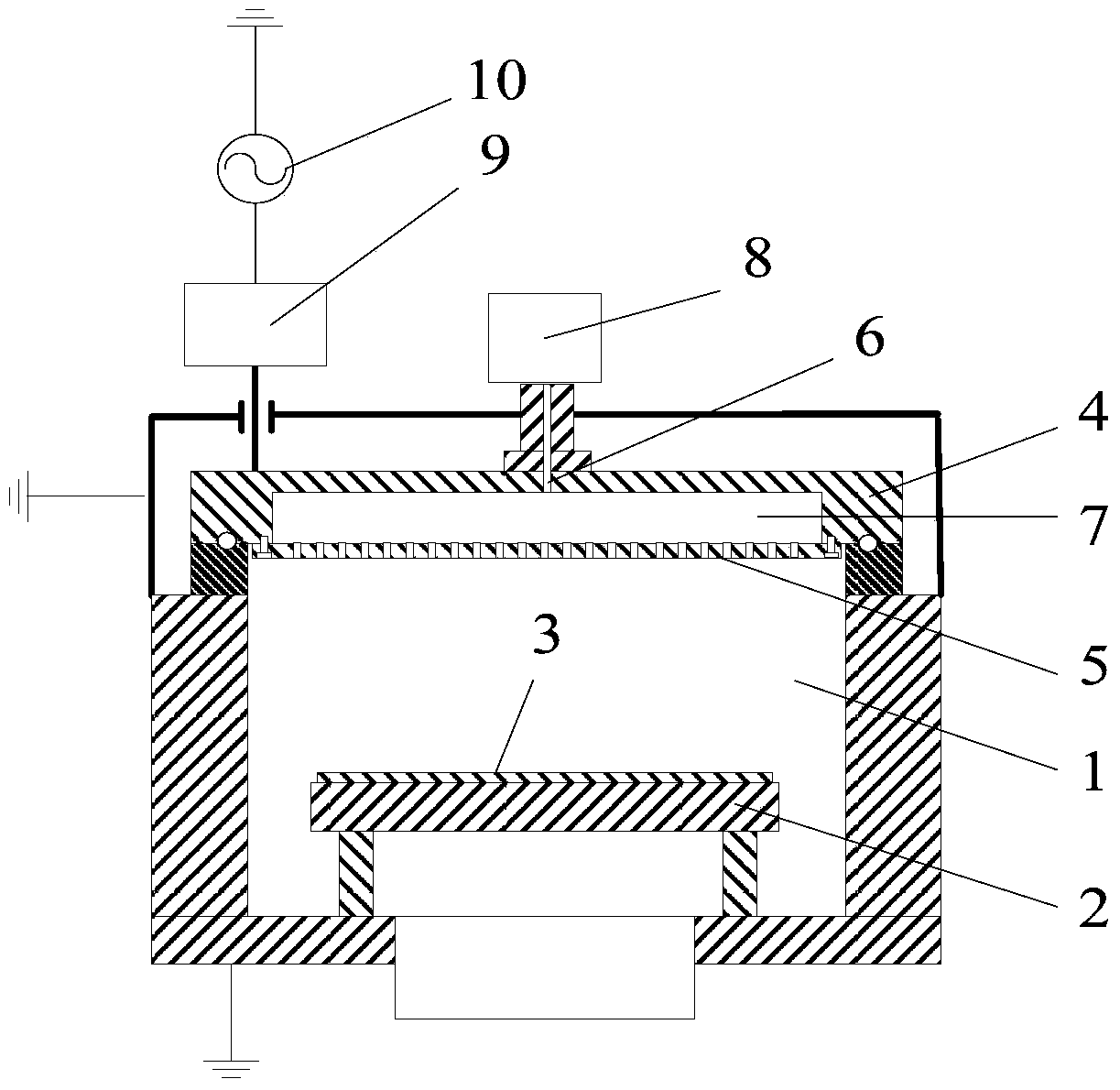

Device for preparing graphene crystal film through electron beam scanning

ActiveCN112144123AAvoid pollutionExtended service lifeAfter-treatment apparatusPolycrystalline material growthPolymer thin filmsBeam scanning

The invention discloses a device for preparing a graphene crystal film through electron beam scanning. The device comprises a vacuum chamber and an electron gun arranged at the top of the vacuum chamber, a workbench is arranged in the vacuum chamber, an insulating plate is arranged on the workbench, a metal substrate is arranged on the insulating plate, and a carbon polymer film is arranged on themetal substrate; a carbon powder adsorption cover is adopted to cover an area from the outer side of the carbon polymer film to an electron beam output port in the top of the inner side of the vacuumchamber, the carbon powder adsorption cover comprises an inner layer and an outer layer, a plurality of insulating ceramic blocks are arranged between the inner layer and the outer layer, the inner layer is grounded, and the outer layer is electrically connected with a first direct-current power supply, so that a first adsorption electrostatic field is formed between the inner layer and the outerlayer; wherein the first adsorption electrostatic field is used for adsorbing carbon powder generated in the process of preparing the graphene crystal film through electron beam scanning. Carbon powder generated in the machining process can be adsorbed to the maximum extent through the carbon powder adsorption cover, pollution of the carbon powder generated in the machining process to an electronic gun and a vacuum chamber is effectively prevented, and the service life of equipment is prolonged.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Measuring method of grain layer thickness and judging method of grain layer abnormality

ActiveCN109883365BClear structureOvercoming the phenomenon of easy chargingUsing wave/particle radiation meansMaterial analysis by measuring secondary emissionTest sampleMaterials science

The invention discloses a crystal particle layer thickness measuring method. The crystal particle layer thickness measuring method at least comprises the following steps that S10: FIB is used for treating to-be-tested crystal particles to a target area; S20: a mixed acid solution composed of mixed CH<3>COOH, HNO<3> and HF or H<2>O, HNO<3> and HF according to the preset proportion is dropwise addedinto the target area, still standing is conducted for preset time, then washing is conducted, liquid residues on the target area are removed, and a test sample is obtained; and S30: SEM is used for observing and measuring the test sample under a preset voltage. The invention further discloses a crystal particle layer abnormity judgement method, thicknesses of all layers in a crystal particle structure is measured through the crystal particle layer thickness measuring method and compared with standard values, whether abnormity exists in the thicknesses of the chip crystal particles or not is judged, and the abnormity exists in which layer is judged. The crystal particle layer thickness measuring method is used for overcoming the defect of a chip crystal particle layer thickness measuring method in the prior art, the operation is easy, and accuracy is high.

Owner:SHENZHEN STS MICROELECTRONICS CO LTD

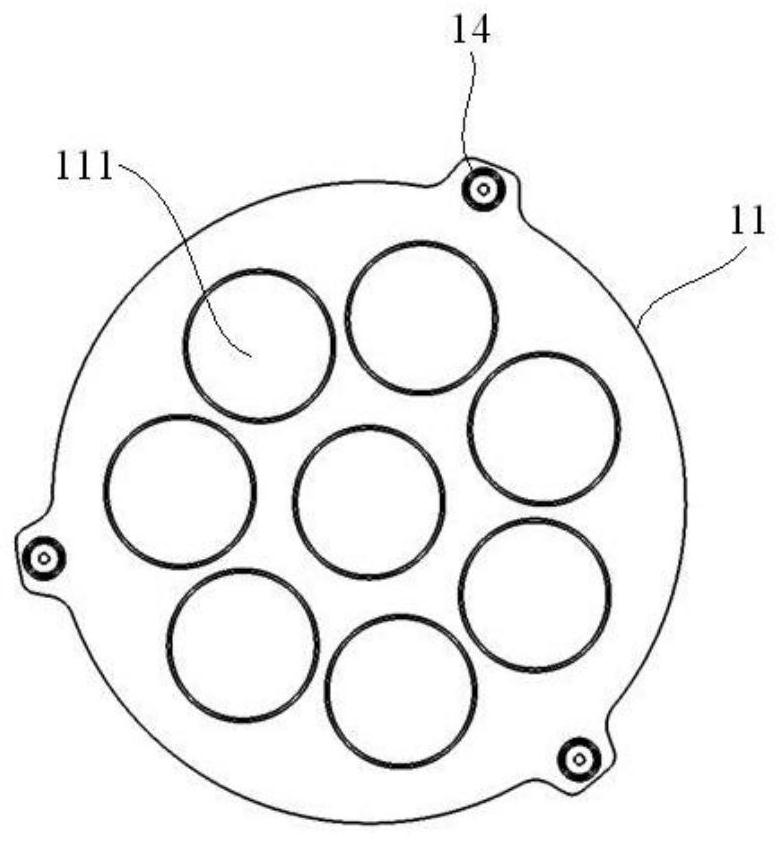

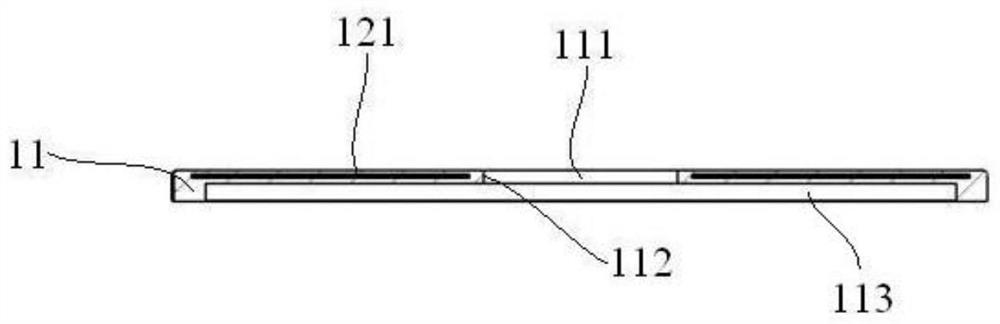

Compression ring assembly and semiconductor process chamber

PendingCN112151436AAchieve liftingAvoid top breakageElectric discharge tubesSemiconductor/solid-state device manufacturingWaferingMechanical engineering

The invention provides a compression ring assembly and a semiconductor process chamber, a compression ring is used in cooperation with a chuck, the compression ring fixes a tray to the chuck through alifting device, a compression ring assembly comprises an electrostatic assembly and an insulated compression ring body, the compression ring body is used for making contact with a tray, and through holes are formed in the compression ring body. The through holes are used for exposing wafers carried on the tray; the electrostatic assembly is connected with the compression ring body and used for enabling the compression ring body to generate electrostatic adsorption force so as to adsorb the tray through the compression ring body, and the electrostatic assembly is further used for eliminating the electrostatic adsorption force of the compression ring body so as to release the tray. According to the compression ring assembly and the semiconductor process chamber provided by the invention, the probability of damage to the tray can be reduced, the probability of occurrence of a discharge phenomenon can be reduced, the probability of damage to a lower electrode structure can be reduced, thedesign difficulty of the lower electrode structure can be reduced, and the sealing performance of a reaction chamber can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

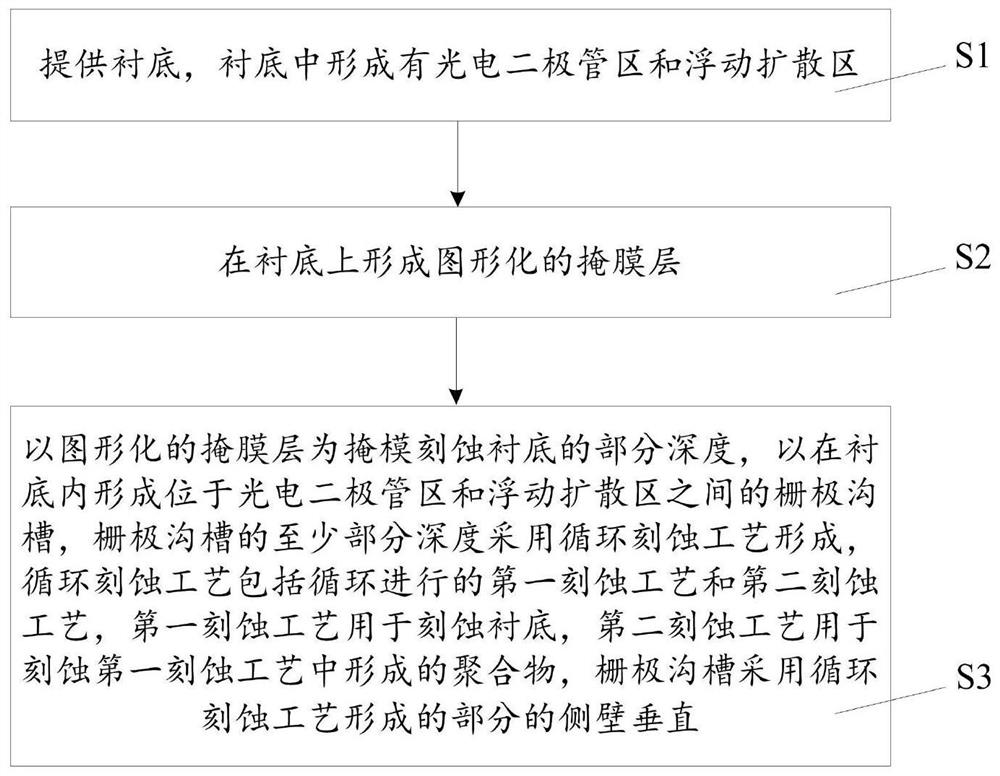

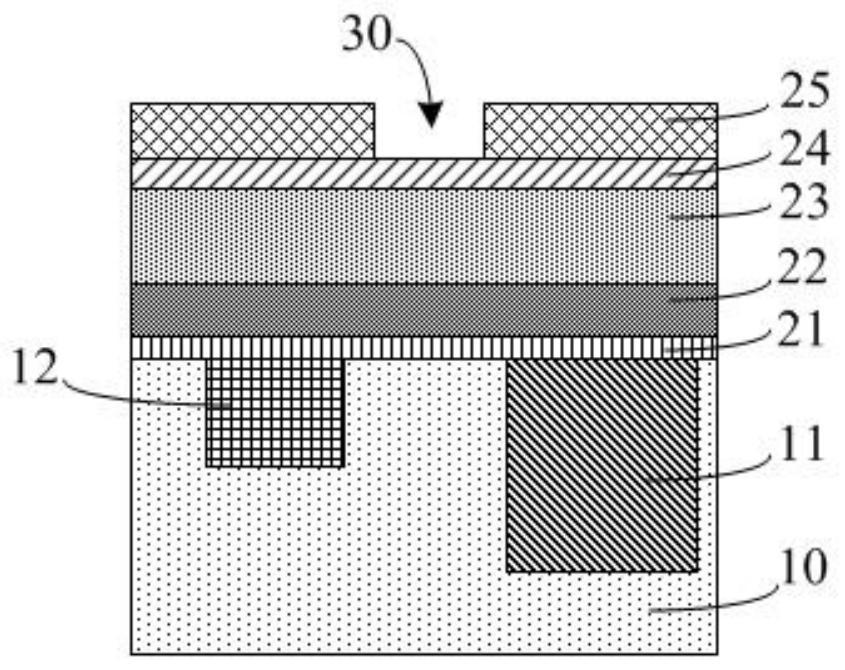

Preparation method of semiconductor device

PendingCN113594031AImprove electrical performanceImproved sidewall uniformitySolid-state devicesRadiation controlled devicesDevice materialEngineering

The invention provides a preparation method of a semiconductor device. The method comprises the steps of providing a substrate, and forming a photodiode region and a floating diffusion region in the substrate; forming a patterned mask layer on the substrate; and taking the patterned mask layer as a mask to etch partial depth of the substrate, so as to form a gate trench located between the photodiode region and the floating diffusion region in the substrate, at least partial depth of the gate trench being formed by a cyclic etching process. The circular etching process comprises a first etching process and a second etching process which are circularly carried out, the first etching process is used for etching the substrate, the second etching process is used for etching a polymer formed in the first etching process, and the side wall of the part, formed by adopting the circular etching process, of the gate trench is vertical. According to the invention, the generation of white pixels is reduced, and the electrical performance of the device is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Tungsten wire components for air purifiers and air purifiers

ActiveCN105880021BGuaranteed purification efficiencyAvoid enteringElectrode carrying meansEngineeringTungsten filament

The invention provides a tungsten filament assembly of an air purifier. The tungsten filament assembly of the air purifier comprises a tungsten filament support, a cover plate, a tungsten filament and a sealing piece. The tungsten filament support is provided with a tungsten filament fixing end. The cover plate is arranged at the tungsten filament fixing end in a covering mode. The tungsten filament is arranged at the tungsten filament fixing end and covered with the cover plate. The sealing piece is arranged between the tungsten filament fixing end and the cover plate. The invention further relates to the air purifier. According to the tungsten filament assembly of the air purifier and the air purifier, a hole position of the tungsten filament assembly is sealed, so that dust is effectively prevented from entering the tungsten filament assembly, and accordingly the probability that discharging is caused due to the fact that dust is excessively accumulated in the tungsten filament assembly is lowered; and the air purification efficiency is guaranteed, and the generation quantity of ozone is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

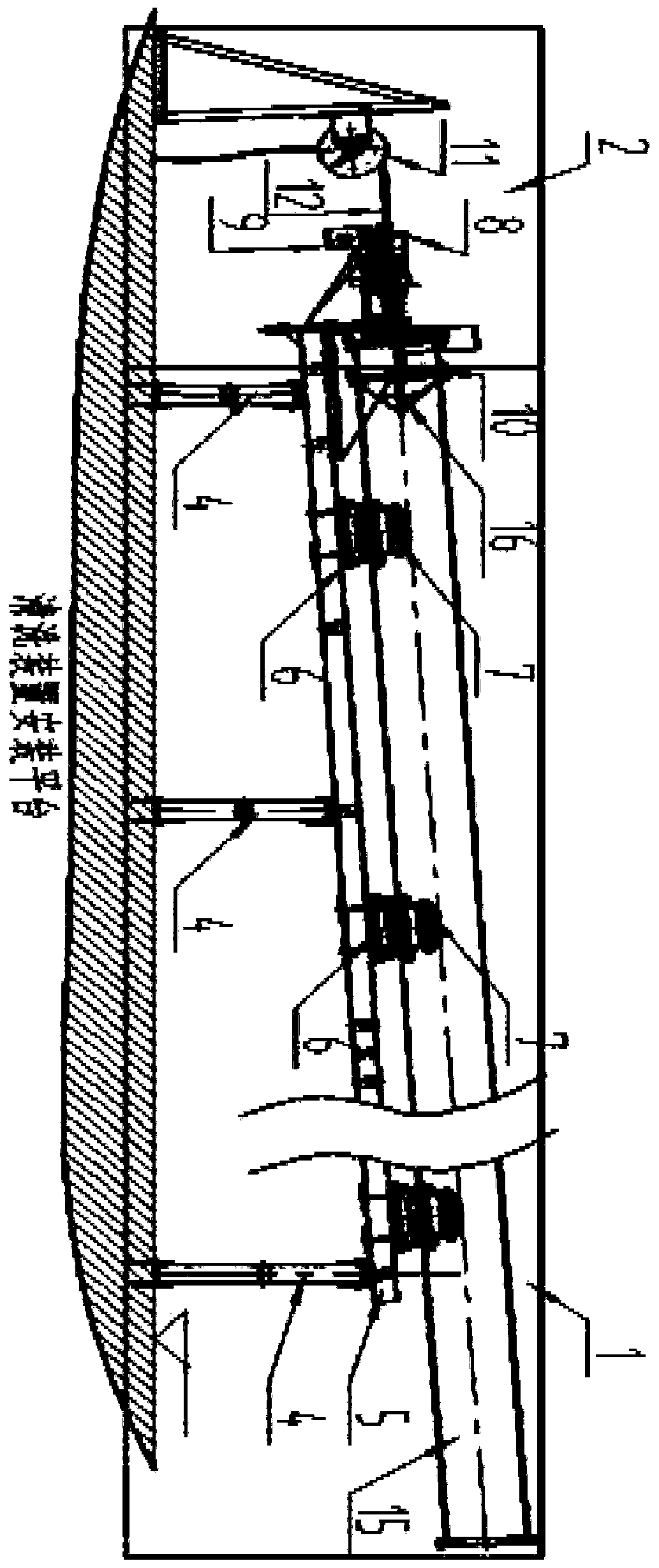

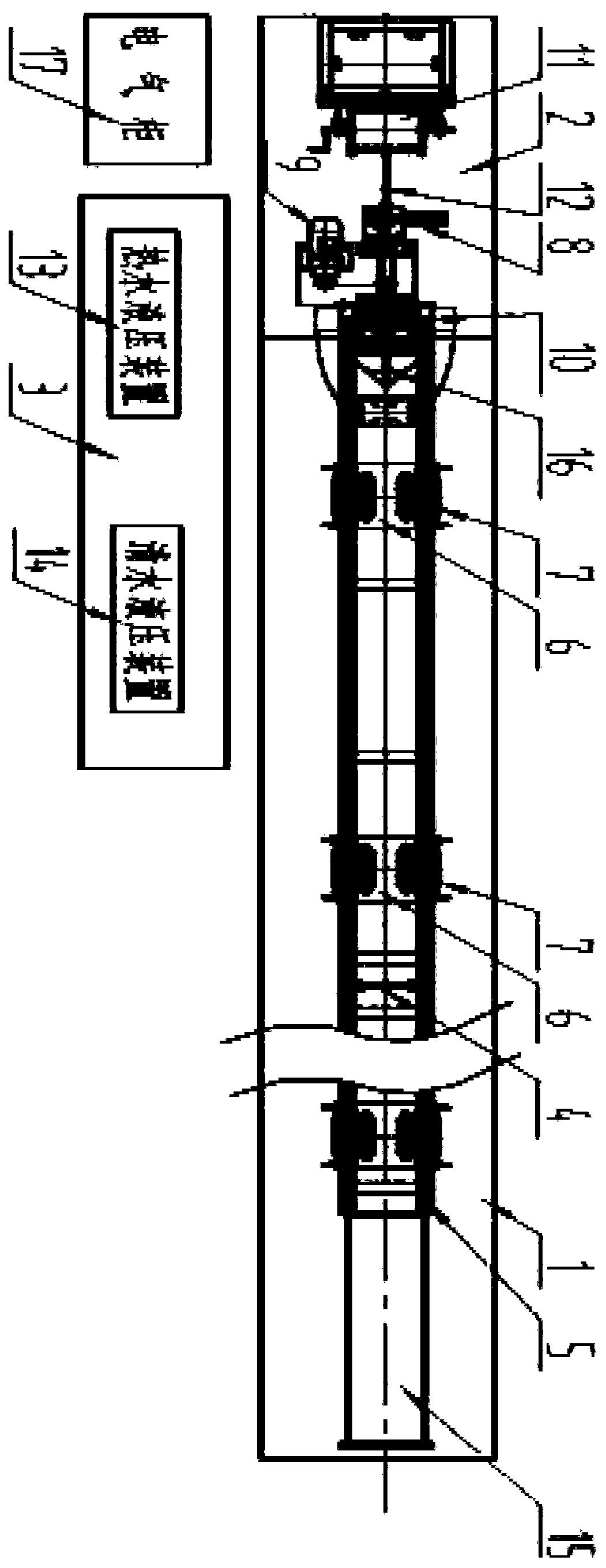

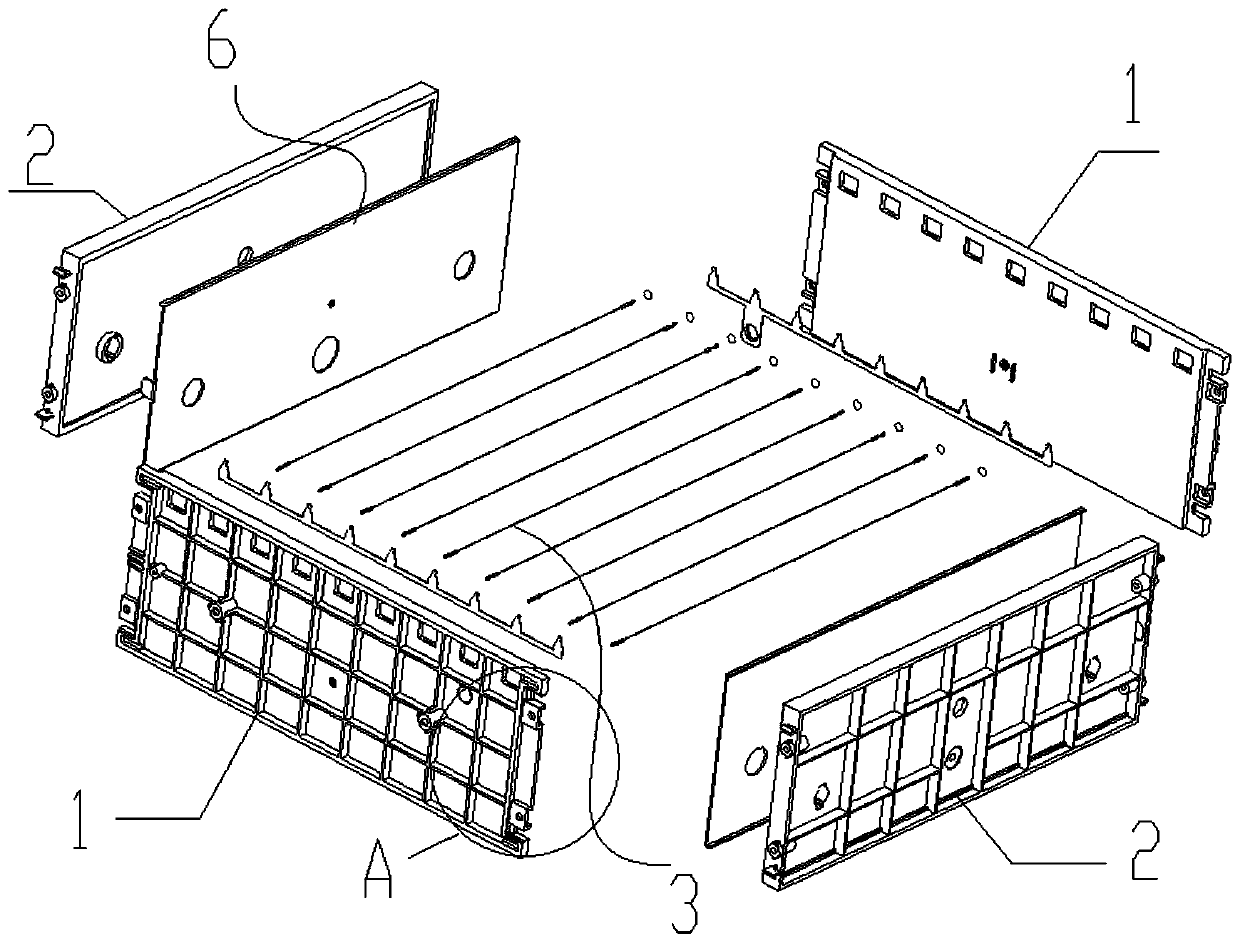

Self-propelled GIL and GIS shell inner cavity cleaning device

PendingCN111589800AImprove assembly pass rateImprove some mechanizationHollow article cleaningElectric machineryEngineering

Owner:江苏恒高电气制造有限公司

A kind of brazing method without splicing rotating target

ActiveCN110948071BSolve the problem of large temperature difference in the heating processAvoid crackingSoldering apparatusTemperature controlMetallurgy

The invention relates to a brazing method for non-splicing rotating target materials, which comprises the following steps: using an ultrasonic welding head to oscillate the brazing material into the inner surface of a target tube and the outer surface of a back tube; installing the target tube and the back tube on a positioning base Then connect the brazing material disk to the upper end of the target tube; place the assembled brazing device in the electric heating constant temperature blast drying oven, set the temperature control heating curve through the thermostat, after the holding time expires, the natural Cool to room temperature; after the whole device is cooled to room temperature, remove the residual brazing material on the brazing material disk with a scraper, and remove the brazing material disk and the positioning base to obtain the brazed rotating target material. The brazing method can solve the problem of large temperature difference in the heating process of the target tube and the back tube during the brazing process of the target material; the brazing method can easily control the heating rate, and can avoid the problem of cracking of the target material due to excessive heating.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

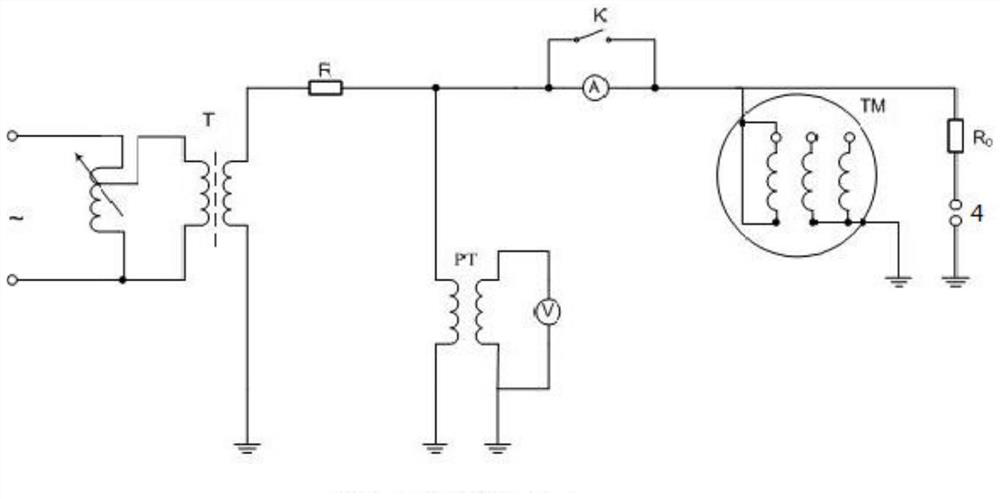

A process method for preventing false breakdown of wire rods when stator windings of large motors withstand AC voltage

ActiveCN110957875BSolve the problem of false breakdownQuality assuranceTesting dielectric strengthApplying solid insulationOvervoltageWire rod

The invention discloses a process method for preventing false breakdown of wire rods when the stator winding of a large motor is AC withstand voltage. The surface potential gradient of the iron block at the end and the end hoop bracket is evenly distributed, which effectively controls the generation of weak arc discharge caused by the scattered voltage of the iron block at the end of the winding and the end hoop bracket. The present invention adopts correct and effective overvoltage protection measures to prevent wire rods from being accidentally broken down by overvoltage during the AC withstand voltage test, reduce the loss cost of product manufacturing, ensure the installation quality and progress, and restore the authenticity of the test. , which improves the accuracy of the test. The invention is a novel technical scheme with strong practicability, simple and convenient operation and easy popularization.

Owner:HARBIN ELECTRIC MASCH CO LTD

Terminal device having meta-structure

ActiveUS9231443B2Minimize impactImprove electricity efficiencyBatteries circuit arrangementsElectromagnetic wave systemEffective powerTerminal equipment

Owner:FOUND OF SOONGSIL UNIV IND COOP

A device for preparing graphene crystal thin films by electron beam scanning

ActiveCN112144123BAvoid pollutionExtended service lifeAfter-treatment apparatusPolycrystalline material growthPolymer thin filmsBeam scanning

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Epoxy cast dry transformer

InactiveCN101308721BReasonable designCreative ideaTransformers/inductances coils/windings/connectionsEpoxyTransformer

Disclosed is an epoxy resin cast dry-type transformer, which comprises a low-voltage winding, two high-voltage windings, an iron core, an upper heel piece, a lower heel piece, an upper clamp and a lower clamp. The low-voltage winding is arranged at the inner layer of the loop and the high-voltage windings are arranged at the outer layer of the loop. The low-voltage winding is made of clutch gold and is provided with an insulating interlayer which is presoaked with DMD resin. The initial loops of the high-voltage windings are located at one end of the whole loop, and the starting end of the first coil of each layer of the high-voltage windings is connected with the finishing end of the last coil of the next layer. The number of the coils of the windings descends from the inner layer to theouter layer, making the windings developing into antiparallelogram structures; a soft gridding cloth layer is arranged between each two adjacent layers; the whole medium is epoxy resin and solvent-free gridding material is arranged between the outer layers of the windings at both ends of the whole loop. The epoxy resin cast dry type transformer is reasonable in design, novel in design, large in power, and small in size, and is convenient to install and easy to maintain. The epoxy resin cast dry type transformer is safe, stable and reliable and is long in service life and low in using cost andrequires no daily maintenance. The epoxy resin cast dry-type transformer has strong practicability and is applicable in power supplying departments and power consuming departments.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

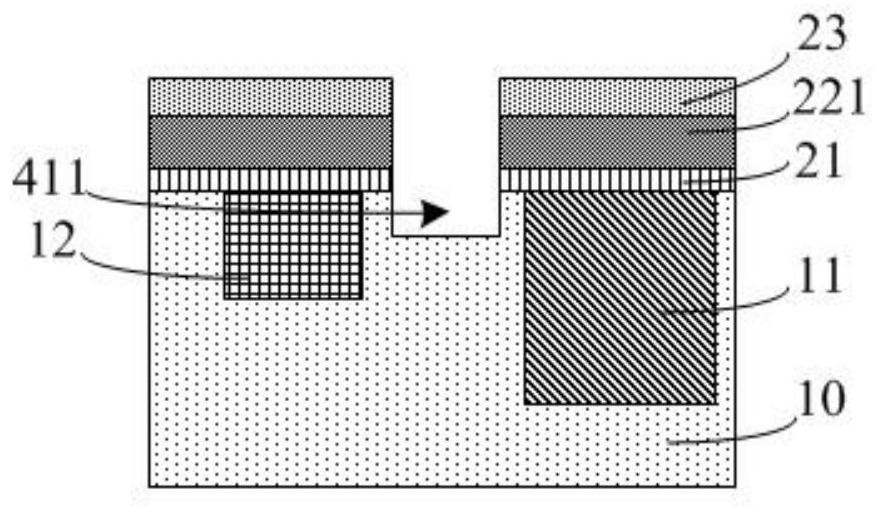

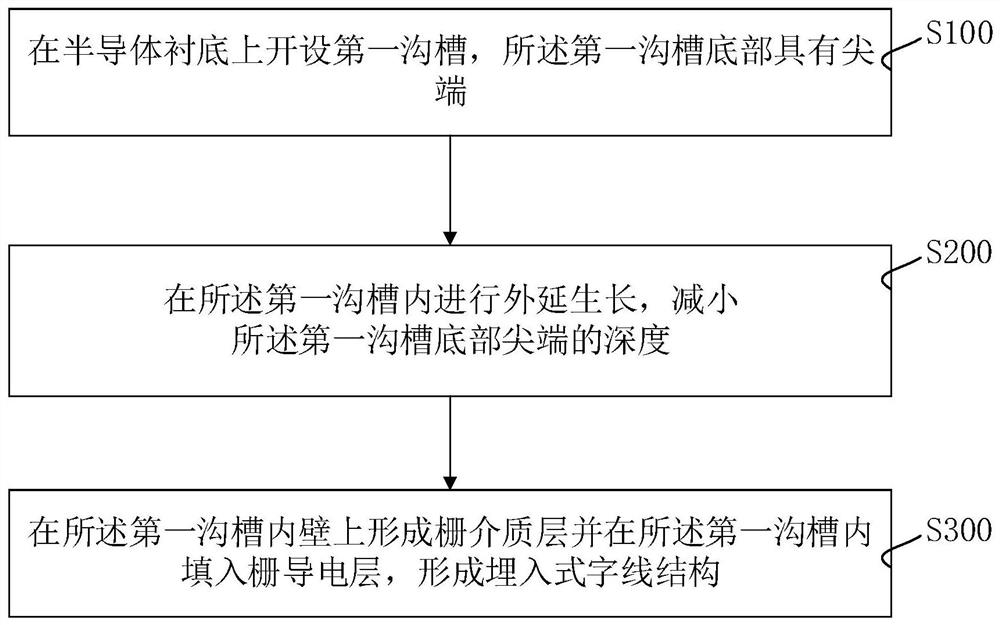

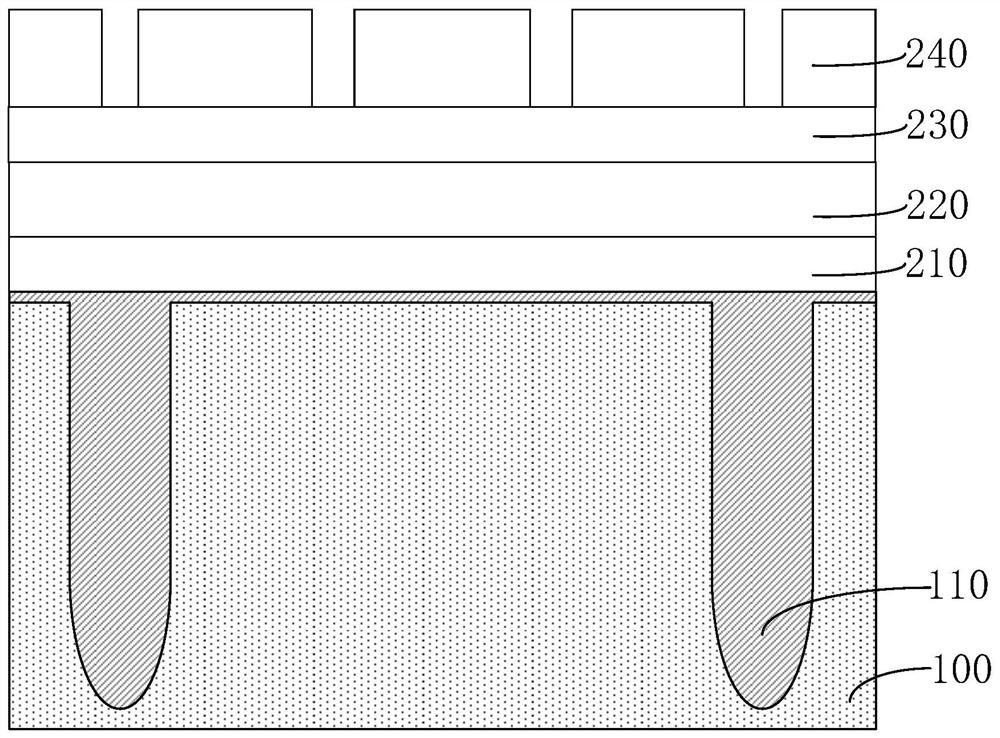

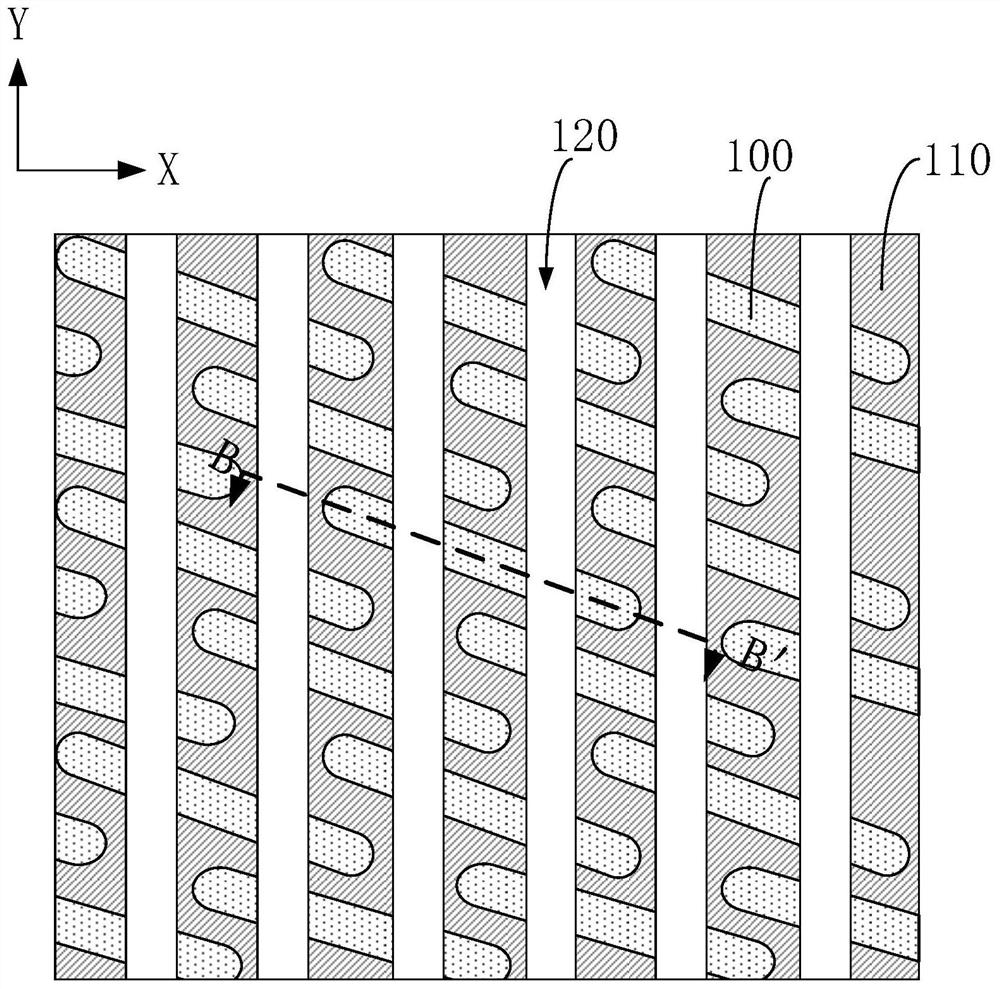

Embedded word line structure preparation method

PendingCN113675143AReduce discharge phenomenonImprove stabilityTransistorSemiconductor/solid-state device manufacturingGate dielectricEngineering

The invention relates to an embedded word line structure and a preparation method thereof, and the preparation method comprises the steps: forming a first groove in a semiconductor substrate, and enabling the bottom of the first groove to be provided with a tip; carrying out epitaxial growth in the first groove, and reducing the depth of the tip of the bottom of the first groove; and forming a gate dielectric layer on the inner wall of the first groove and filling a gate conductive layer in the first groove to form an embedded word line structure. According to the preparation method, the tip depth of the first groove is reduced through the epitaxial growth process, so that the tip discharge phenomenon is weakened, and the device performance is improved.

Owner:CHANGXIN MEMORY TECH INC

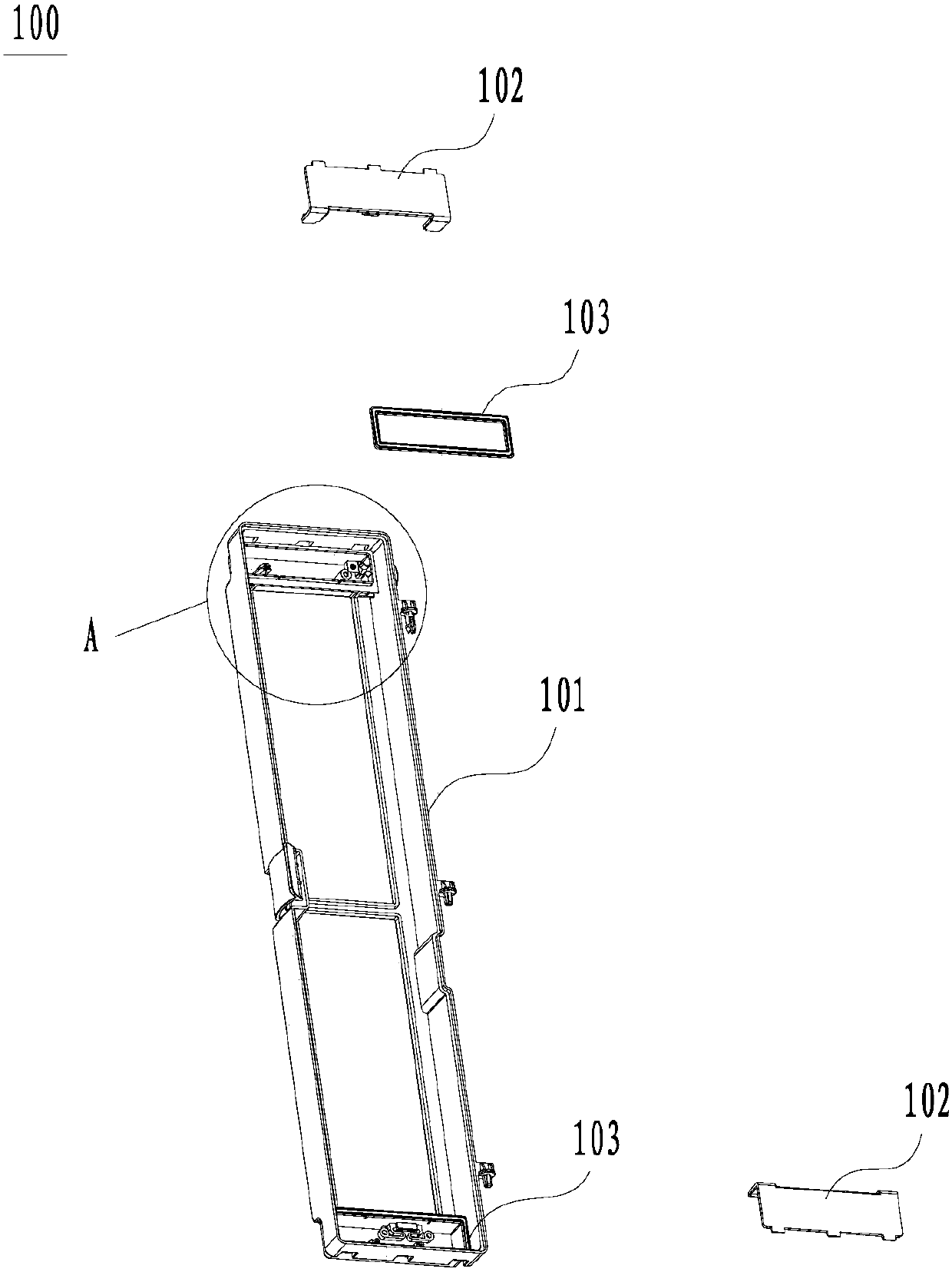

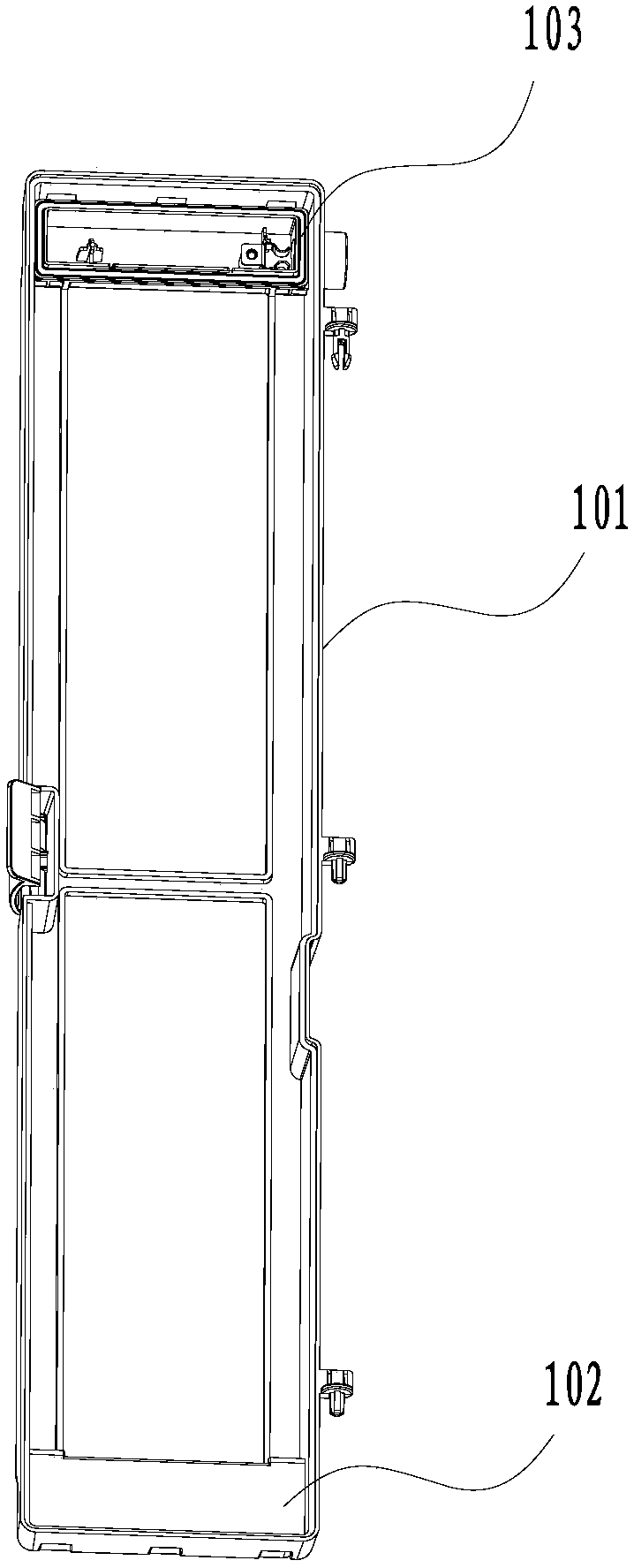

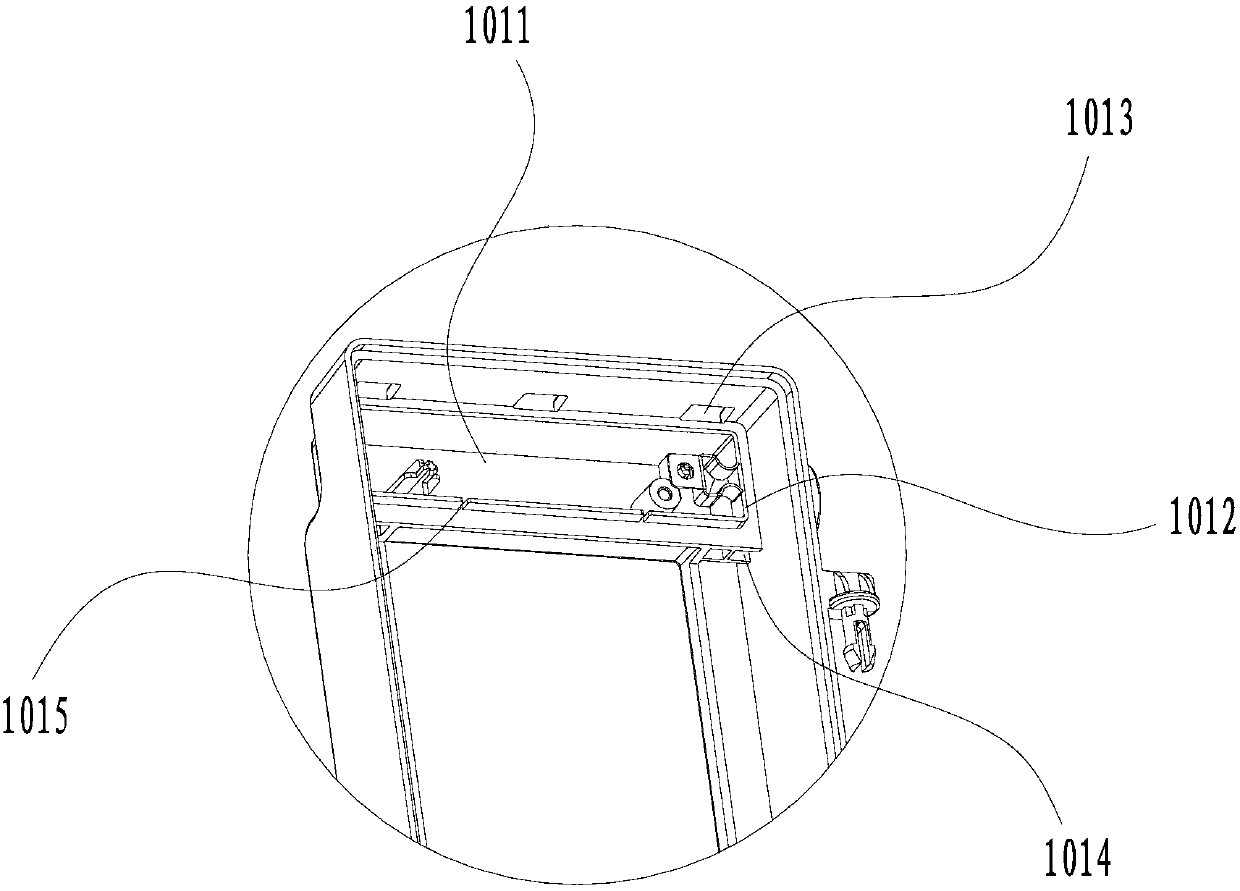

Plasma generating device

PendingCN111083866AConsistent layoutAvoid dischargeDeodrantsPlasma techniqueEngineeringInjection moulding

The invention provides a plasma generating device which comprises a housing and tungsten filaments; the housing comprises two connecting plates oppositely arranged and two supporting plates arranged between the two connecting plates; the two ends of each tungsten filament are connected to the connecting plates respectively; a plurality of elastic pieces are arranged at the positions, correspondingto the ends of the tungsten wires, of the connecting plate, the elastic pieces and the tungsten wires are consistent in layout, the ends of the tungsten wires are suitable for being connected to theelastic pieces, and the elastic pieces and the connecting plate are integrally formed in an injection molding mode. According to the invention, a spring is omitted due to the fact that the end part ofthe spring is easy to generate burrs in the machining process, so that the spring is easy to discharge in a high-voltage environment. And after the spring is canceled, the discharge generated by burrs can be effectively avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Vibration bionic anti-insect cable

ActiveCN110428932BStable storageStable jobInsulated cablesAnimal repellantsStructural engineeringElectric cables

The present invention relates to a vibration bionic anti-insect cable. The vibration bionic anti-insect cable includes a wire core and a protective layer wrapped outside the wire core; a liquid storage cavity is set outside the protective layer; The cavity is filled with vibrating glue with a low melting point; a vibrating layer is wrapped outside the liquid storage cavity; vibrating coils are equidistantly arranged in the peripheral wall of the vibrating layer, and the ring surfaces of each vibrating coil are along the The radial extension of the vibrating layer; a magnetic vibrating piece matching each of the vibrating coils is also installed in the peripheral wall of the vibrating layer, and each of the magnetic vibrating pieces contacts the vibrating glue; There are liquid guide holes, each of which runs through the vibration layer and communicates with the liquid storage chamber; the cable can effectively disperse snakes, rats, insects and ants around the cable, ensuring safe and stable operation of the buried cable.

Owner:SHENZHEN DONGJIAXIN CABLE&WIRE

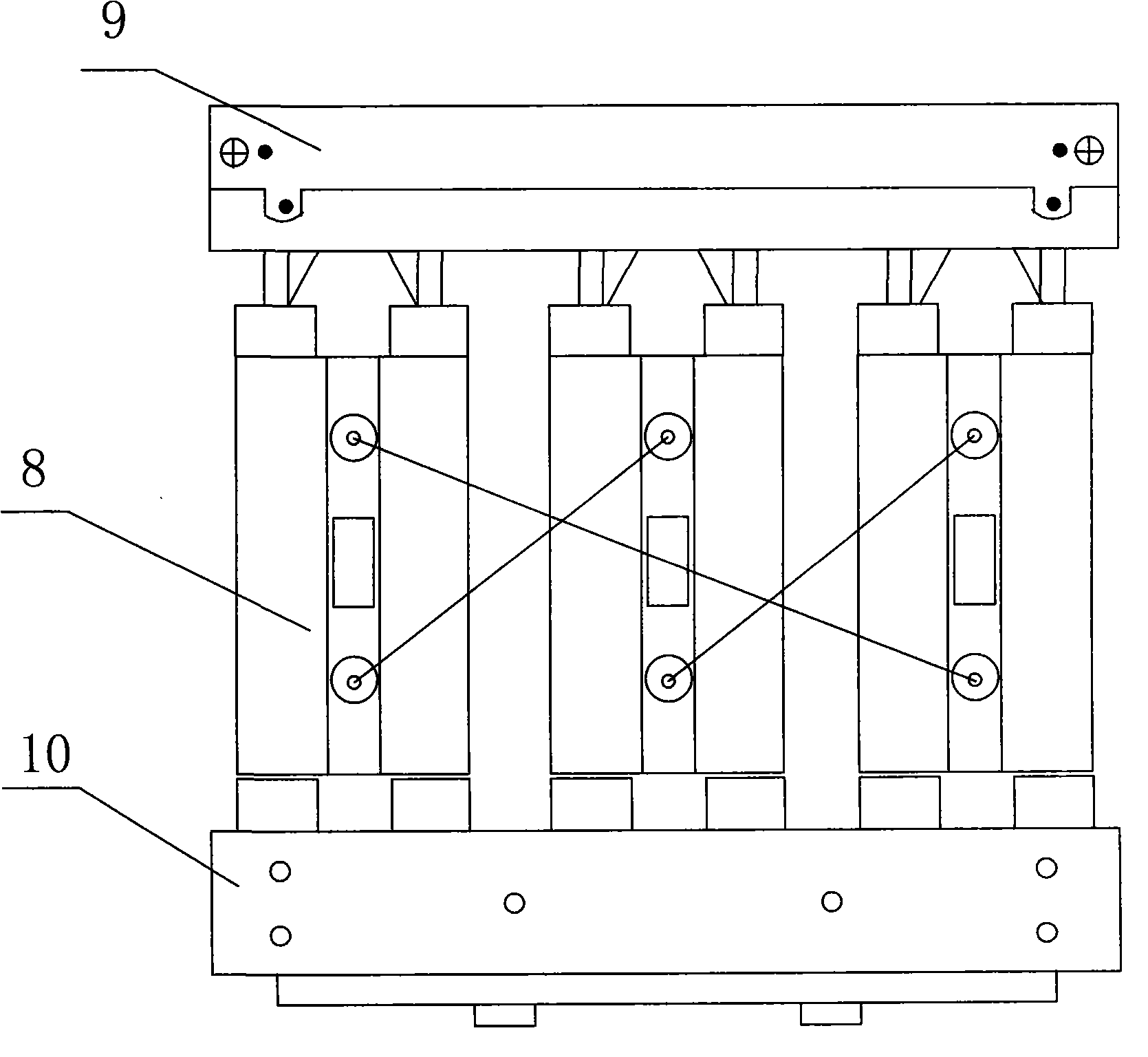

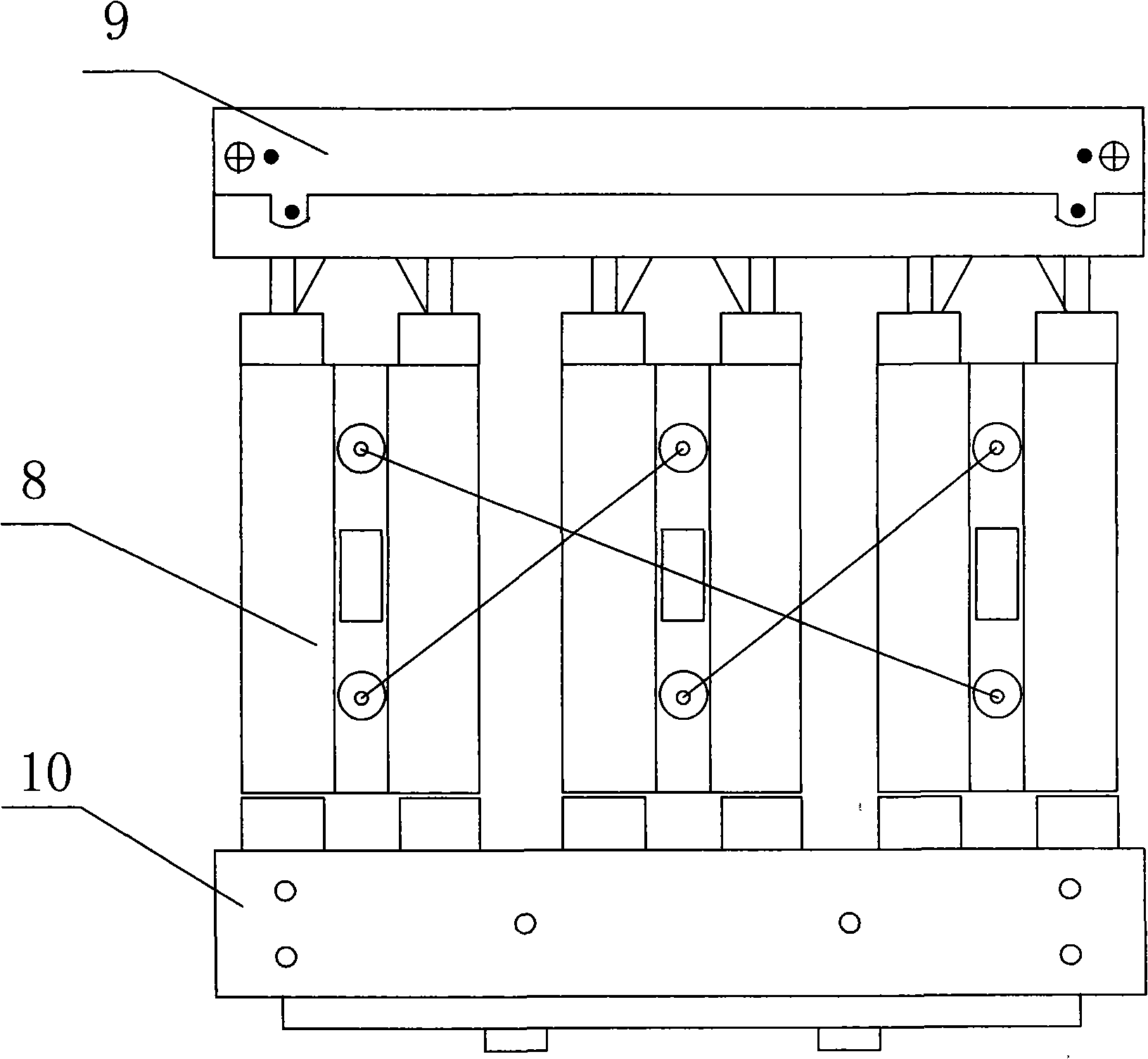

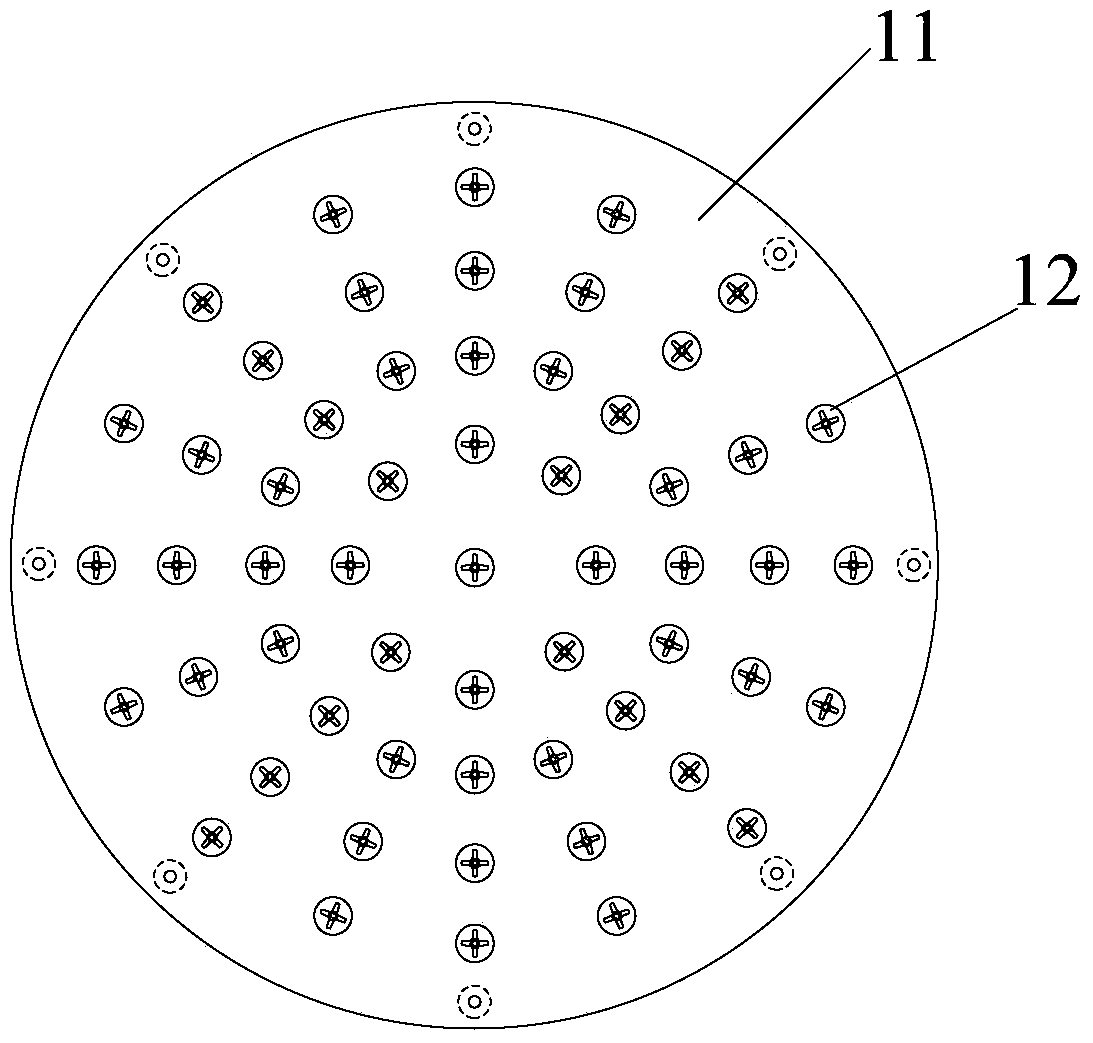

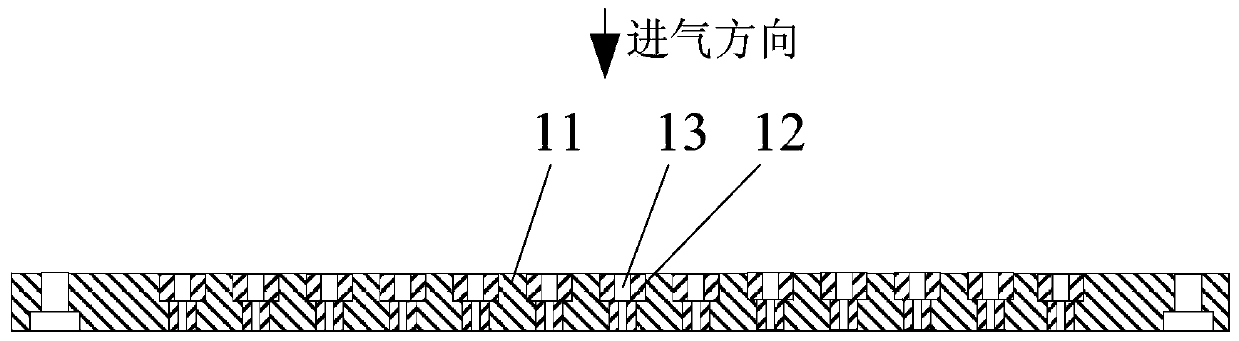

Intake components and reaction chamber

ActiveCN106702350BLow densityWeaken energyChemical vapor deposition coatingEngineeringReaction chamber

The invention provides an air inlet assembly and a reaction cavity. The air inlet assembly is arranged on the top inside the reaction cavity and comprises an air inlet plate and a plurality of air inlet parts distributed in the air inlet plate at intervals, the air inlet parts are made of insulation materials, and are detachably connected with the air inlet plate, and air inlets are formed in the air inlet parts and are used for conveying of process gas to the reaction cavity. According to the air inlet assembly, process uniformity and process stability can be improved, and the use cost of equipment can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

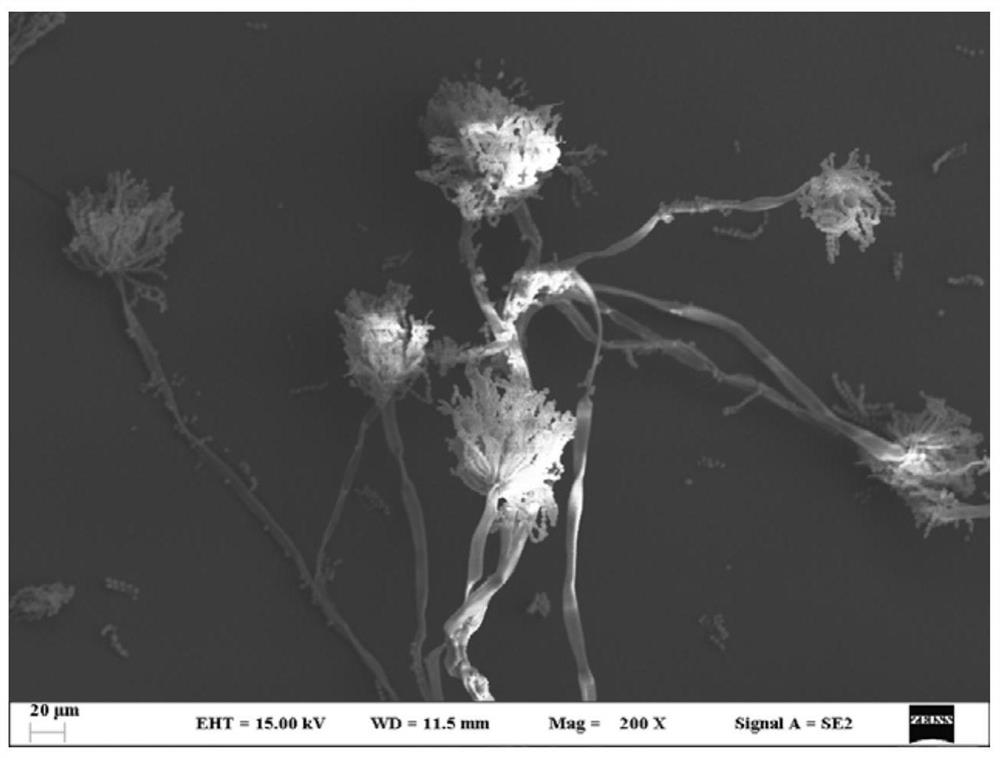

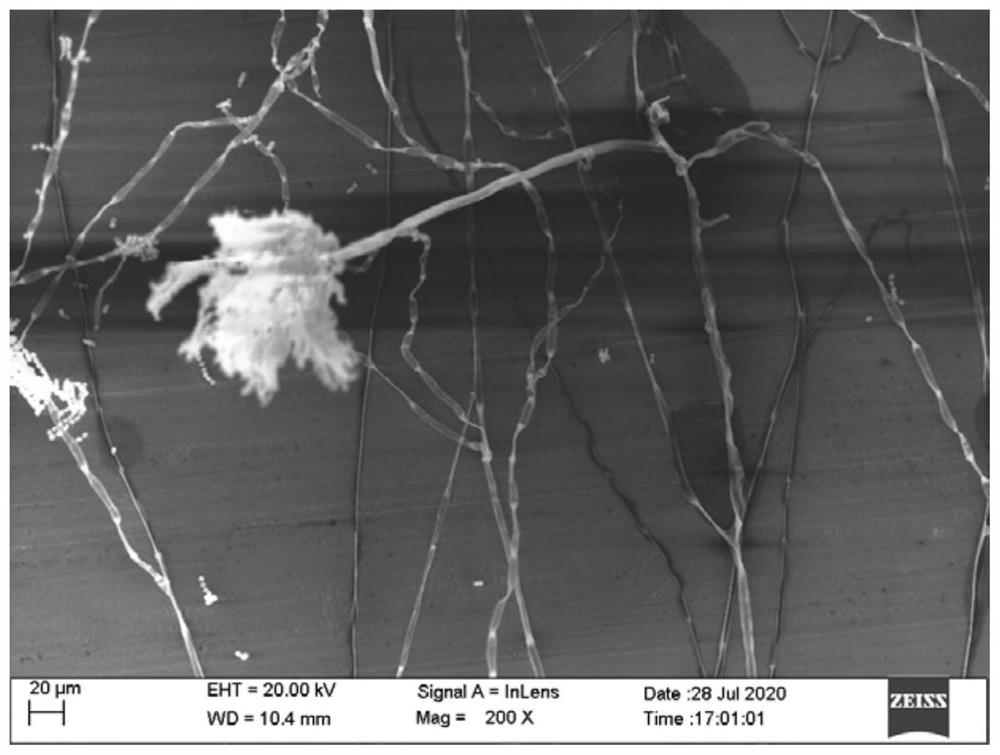

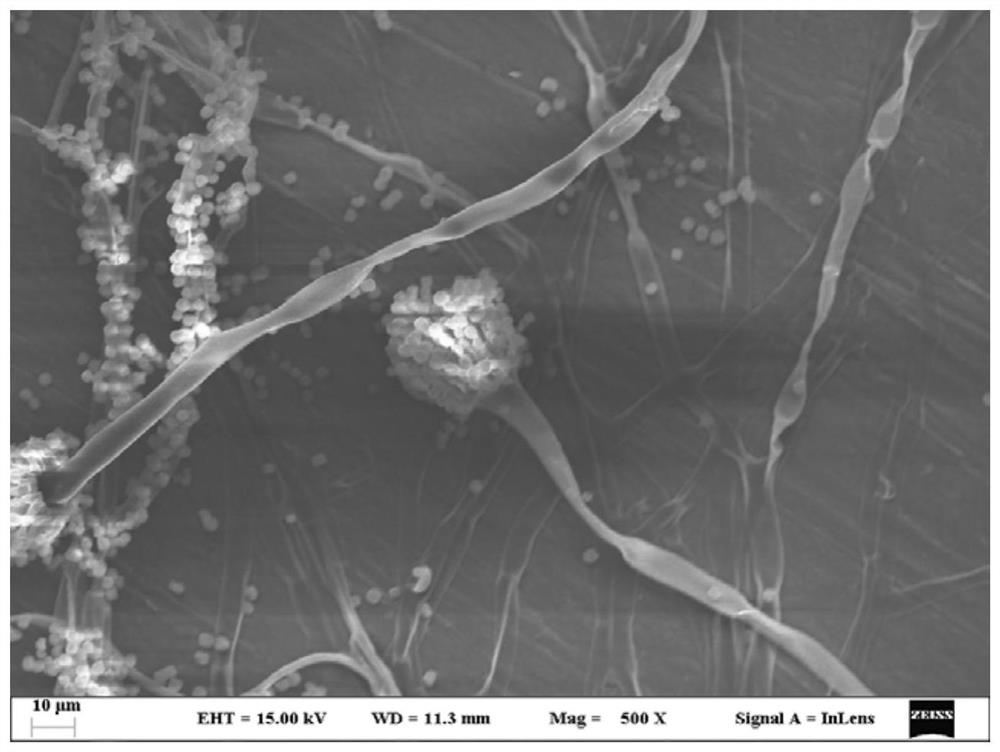

Application of double-conductive aluminum foil adhesive tape

ActiveCN112415033AReduce discharge phenomenonImprove observation effectMaterial analysis using wave/particle radiationSporangiumScanning electron microscope

The invention provides application of a double-conductive aluminum foil adhesive tape, and particularly relates to application of the double-conductive aluminum foil adhesive tape in preparation of afilamentous fungus scanning electron microscope sample. The preparation method of the filamentous fungus scanning electron microscope sample comprises the steps of 1 preparing a solid culture medium;2 preparing the double-conductive aluminum foil adhesive tape; 3 carrying out inoculating and inserting; 4 enabling the double-conductive aluminum foil adhesive tape to climb on a sample table; and 5observing the scanning electron microscope. The double-conductive aluminum foil adhesive tape has excellent conductivity, one surface of the double-conductive aluminum foil adhesive tape is provided with colloidal substances, aspergillus oryzae hyphae growing on the colloidal surface can be firmly attached to the surface of the double-conductive aluminum foil adhesive tape, the hyphae are tightlyattached to the double-conductive aluminum foil adhesive tape, and the positions and shapes of the hyphae, sporangium and spores on a carrier sheet cannot be changed, so that a better electron microscope scanning in-situ observation effect is achieved.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Brazing method for joint-free rotary target

ActiveCN110948071ASolve the problem of large temperature difference in the heating processAvoid crackingSoldering apparatusPipeFiller metal

The invention relates to a brazing method for a joint-free rotary target. The method particularly comprises the steps that brazing materials are subjected to high frequency oscillation to enter the inner surface of a target pipe and the outer surface of a back pipe through an ultrasonic welding head; the target pipe and the back pipe are mounted on a positioning base, and then a brazing filler metal disc is connected to the upper end of the target pipe; an assembled brazing device is placed in an electric heating constant-temperature blasting drying oven, a temperature control heating curve isset through a temperature controller, and after the heat preservation time is reached, the brazing device is naturally cooled to room temperature; and the whole set of device is cooled to room temperature, residual brazing materials on the brazing filler metal disc are removed through a scraper, the brazing filler metal disc and the positioning base are demounted, and the brazed rotary target isobtained. According to the brazing method, the problem that in the target brazing process, the temperature difference in the target pipe and back pipe heating process is large can be solved; and according to the brazing method, the heating rate can be controlled easily, and the problem of cracking due to too fast temperature rise of the target can be avoided.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com