Plasma generating device

A generation device and plasma technology, applied in plasma, electrical components, deodorization, etc., can solve the safety hazards of the tungsten wire installation method, and achieve the effect of avoiding discharge and sparking and not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

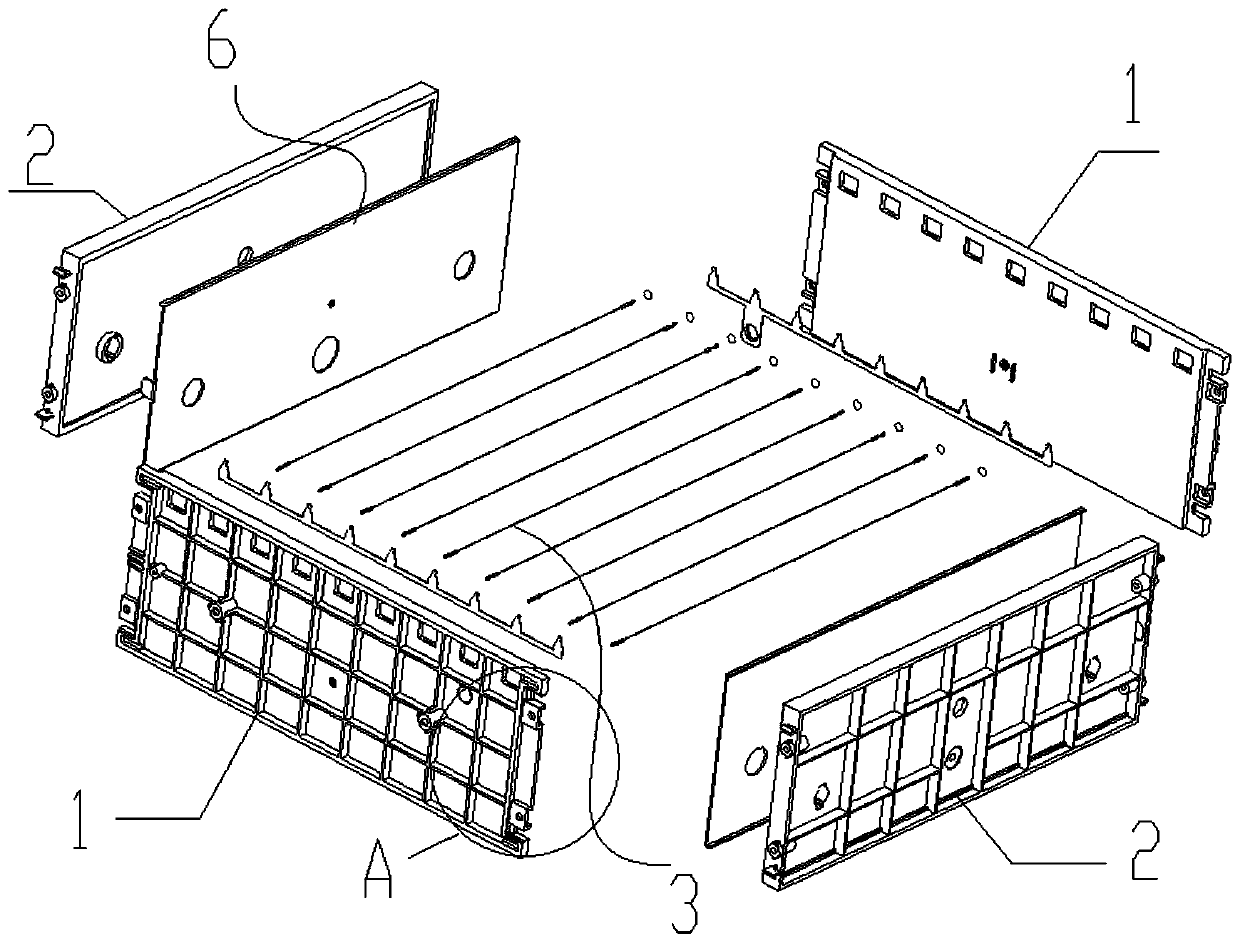

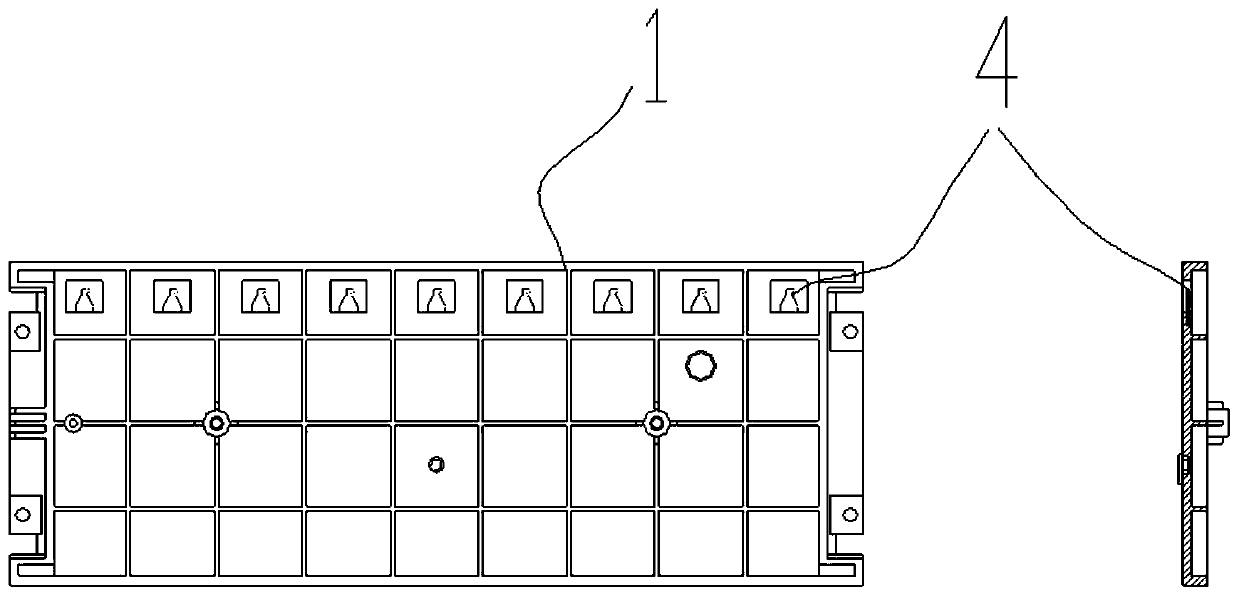

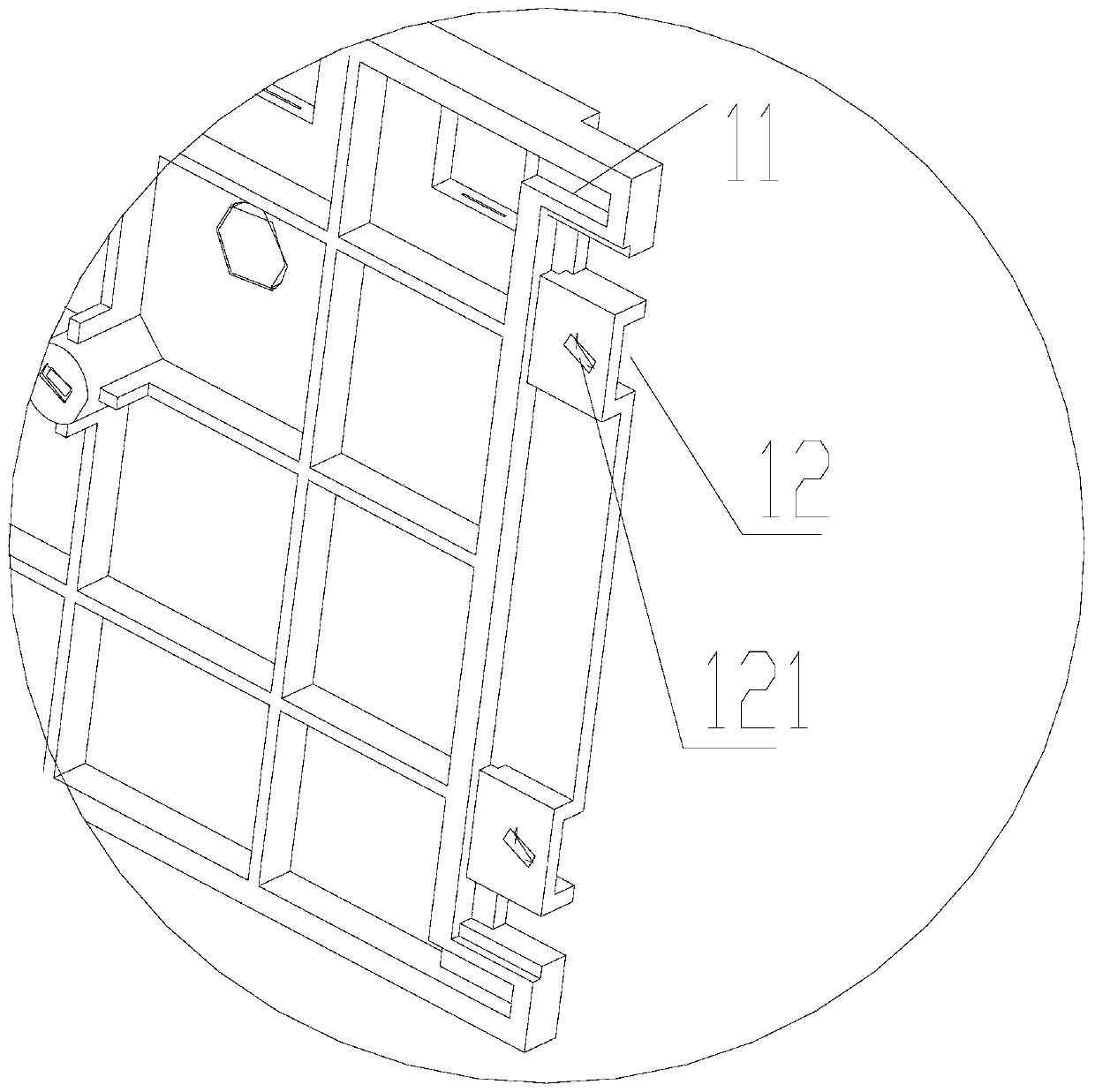

[0036] This embodiment provides a plasma generating device, such as figure 1 As shown, it includes: a housing, including two connecting plates 1 arranged oppositely, and two supporting plates 2 arranged between the two connecting plates 1; several tungsten wires 3, two of the tungsten wires 3 The ends are respectively connected to the connecting plate 1, and a plurality of tungsten wires 3 are arranged parallel to each other; on the connecting plate 1, a number of elastic pieces 4 are arranged at positions corresponding to the ends of the tungsten wires 3, and the elastic pieces 4 is consistent with the layout of the tungsten wire 3, and the end of the tungsten wire 3 is suitable to be connected to the elastic piece 4, and the elastic piece 4 is integrally injection-molded with the connecting plate 1.

[0037] In this embodiment, the structure of the spring is omitted, because the end of the spring is prone to burrs during processing, and therefore discharges are likely to oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com