Manufacturing process of aluminum electrolytic capacitor for reducing point discharge phenomenon

An aluminum electrolytic capacitor, cutting-edge discharge technology, applied in the direction of electrolytic capacitors, capacitors, capacitor terminals, etc., can solve the problems that the product life cannot reach the expected target, short-circuit breakdown, breakdown, etc., to reduce discharge phenomena, prolong product life, The effect of reducing mid-term failure phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

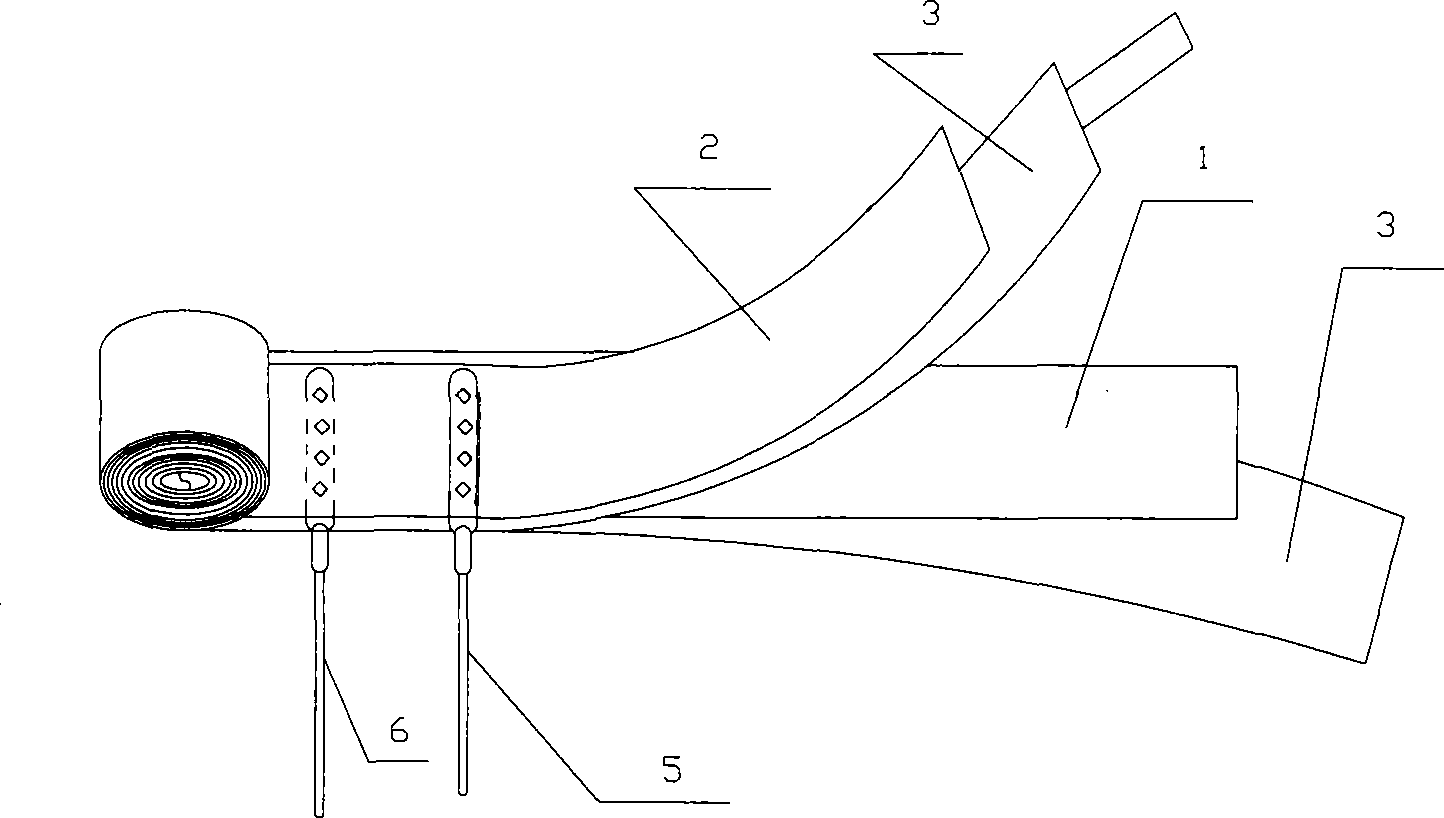

[0016] like figure 1 As shown, it is a schematic diagram of the structure of an aluminum electrolytic capacitor. A manufacturing process of an aluminum electrolytic capacitor that reduces the tip discharge phenomenon is:

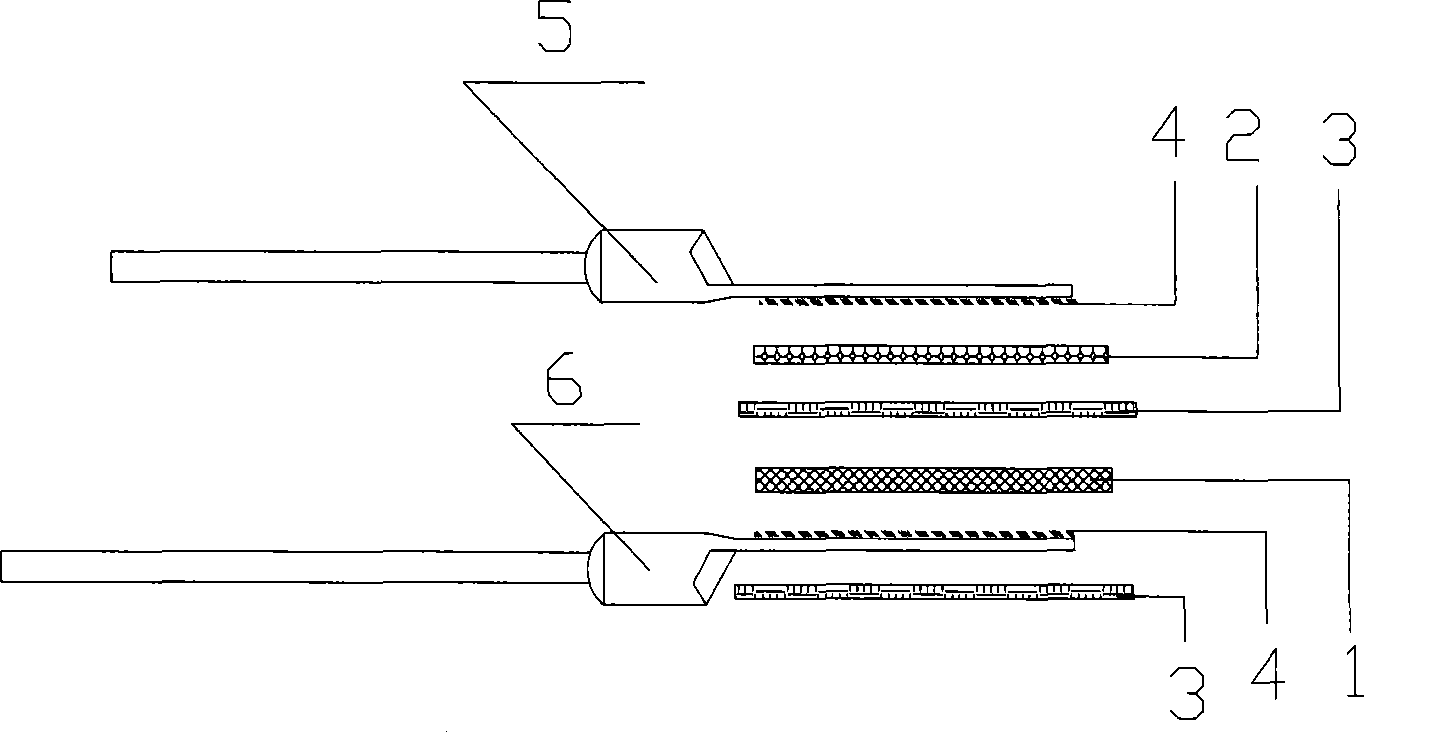

[0017] first step, such as figure 2 As shown, first select the surface of the positive guide pin 6 and the negative guide pin 5, set the tongue of the positive guide pin 6 under the positive electrode aluminum foil 1, and the side with the burr 4 is in contact with the foil surface of the positive electrode aluminum foil 1, and place the negative The tongue of the guide pin 5 is arranged on the negative electrode aluminum foil 2, and the side with the burr 4 is in contact with the foil surface of the negative electrode aluminum foil 2, and a layer of electrolytic paper 3 is respectively arranged between the positive electrode aluminum foil 1 and the negative electrode aluminum foil 2 and under the positive guide pin 6, The burr-free side of the positive gu...

Embodiment 2

[0020] like image 3 As shown, it is a schematic diagram of the manufacturing process of the present invention in Embodiment 2, and a manufacturing process of an aluminum electrolytic capacitor that reduces tip discharge phenomenon is:

[0021] The first step is to select the surface of the positive guide pin 6 and the negative guide pin 5, set the tongue of the positive guide pin 6 under the positive electrode aluminum foil 1, and the side with burrs is in contact with the foil surface of the positive electrode aluminum foil 1, and place the negative The tongue part of the guide pin 5 is arranged on the top of the negative electrode aluminum foil 2, and the side with burrs is in contact with the foil surface of the negative electrode aluminum foil 2, and a layer of electrolytic paper 3 is respectively arranged between the positive electrode aluminum foil 1 and the negative electrode aluminum foil 2 and under the positive guide pin 6, The burr-free sides of the positive guide ...

Embodiment 3

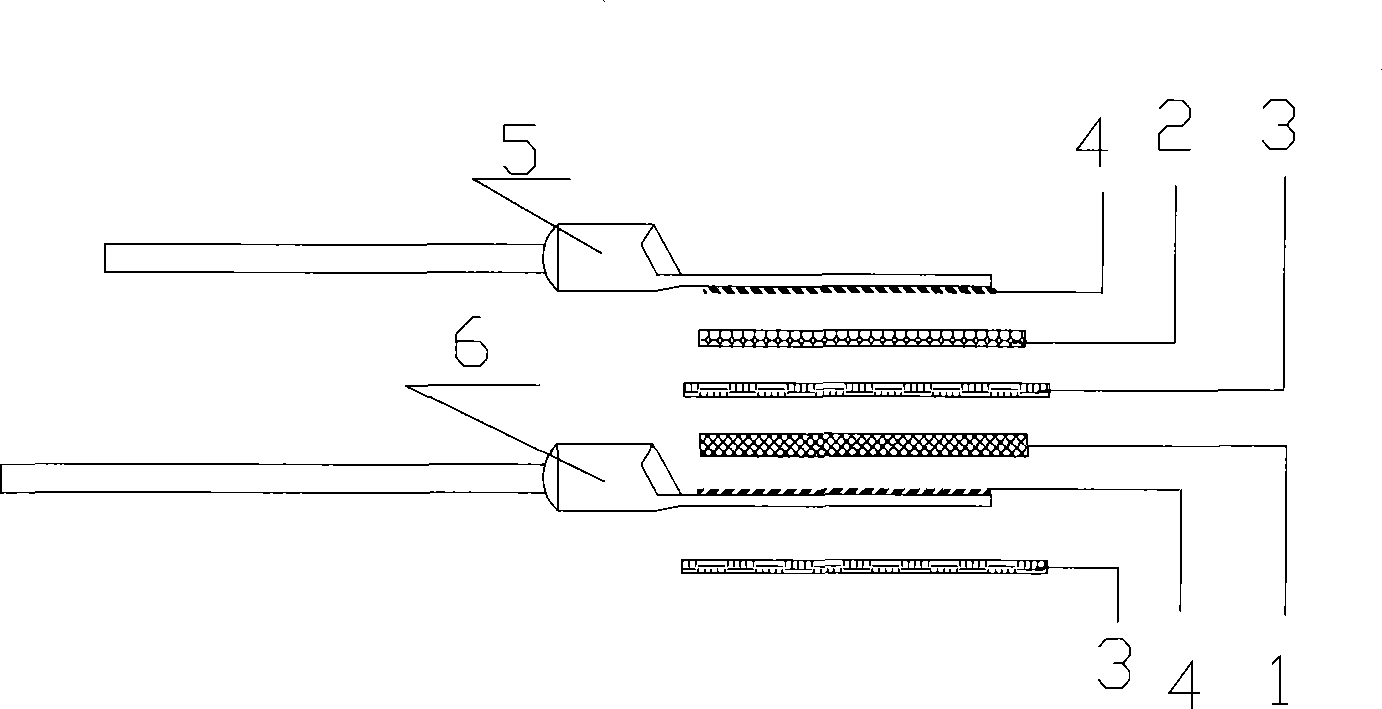

[0024] like Figure 4 As shown, it is a schematic diagram of the manufacturing process of the present invention in Embodiment 3, and a manufacturing process of an aluminum electrolytic capacitor that reduces tip discharge phenomenon is:

[0025] The first step is to select the surface of the positive guide pin 6 and the negative guide pin 5, set the tongue of the positive guide pin 6 under the positive electrode aluminum foil 1, and the side with burrs is in contact with the foil surface of the positive electrode aluminum foil 1, and place the negative The tongue of the guide pin 5 is arranged on the top of the negative aluminum foil 2, and the side with burrs is in contact with the foil surface of the negative aluminum foil 2, and a layer of electrolytic paper 3 is respectively provided between the positive aluminum foil 1 and the negative aluminum foil 2 and under the positive guide pin 6, The positive guide pin 6 and the negative guide pin 5 face each other, and the burrs 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com