Brazing method for joint-free rotary target

A brazing method and technology of rotating target, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to avoid cracking, easy heating rate, and reduce discharge phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare rotating ITO targets with specifications of OD149-ID125*L850mm, where the target tube specification is OD 1 149-ID 1 135*L1 800mm, back pipe specification is OD 2 133-ID 2 125*L 2 850mm.

[0037] Step 1: metallization of the inner surface of the target tube and the outer surface of the back tube: using an ultrasonic welding head to vibrate the brazing material into the surface of the target tube and the back tube to form a thin layer of brazing material. There is no special limitation on the metallization process, and the metallization process well known to those skilled in the art can be used.

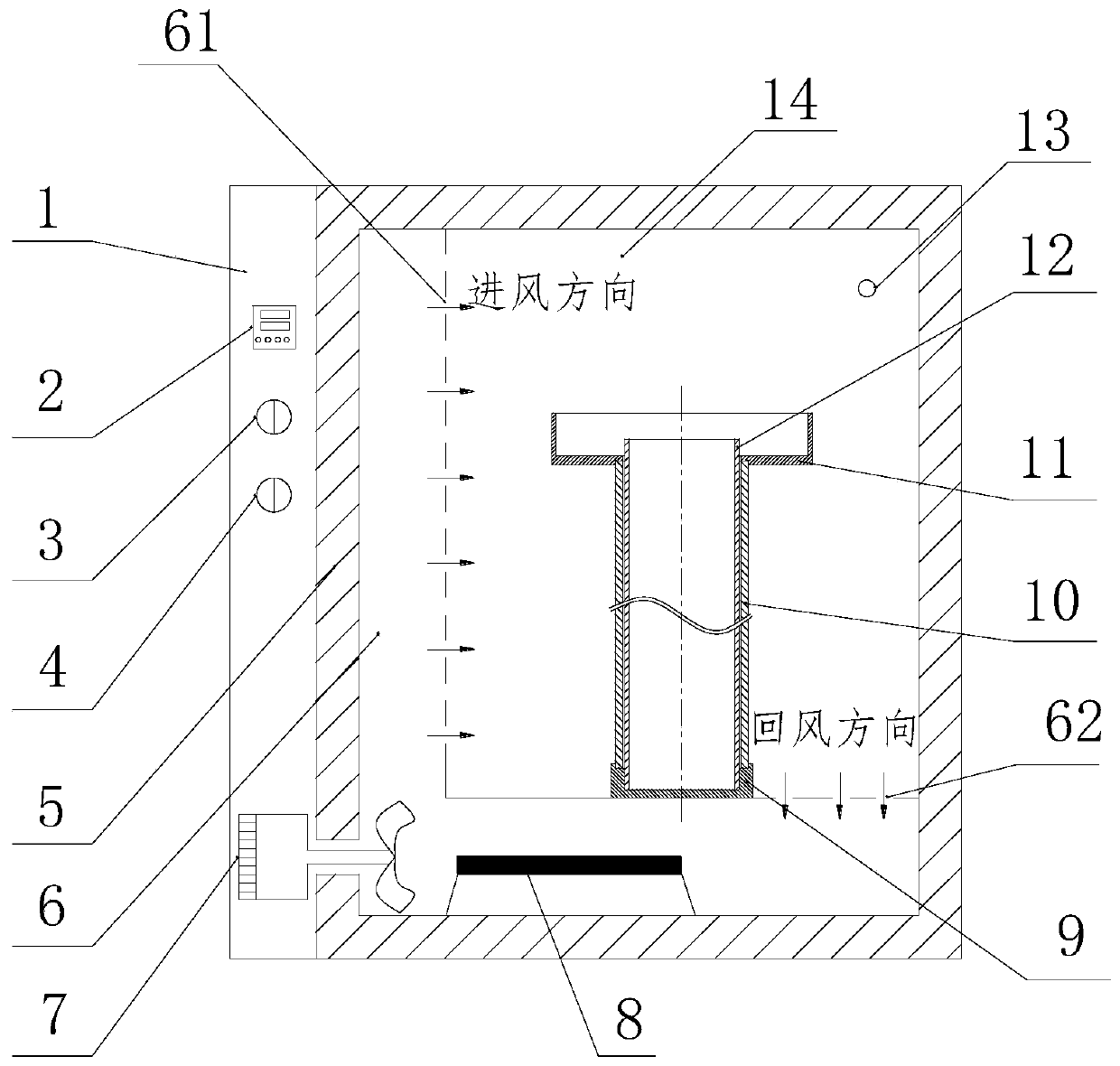

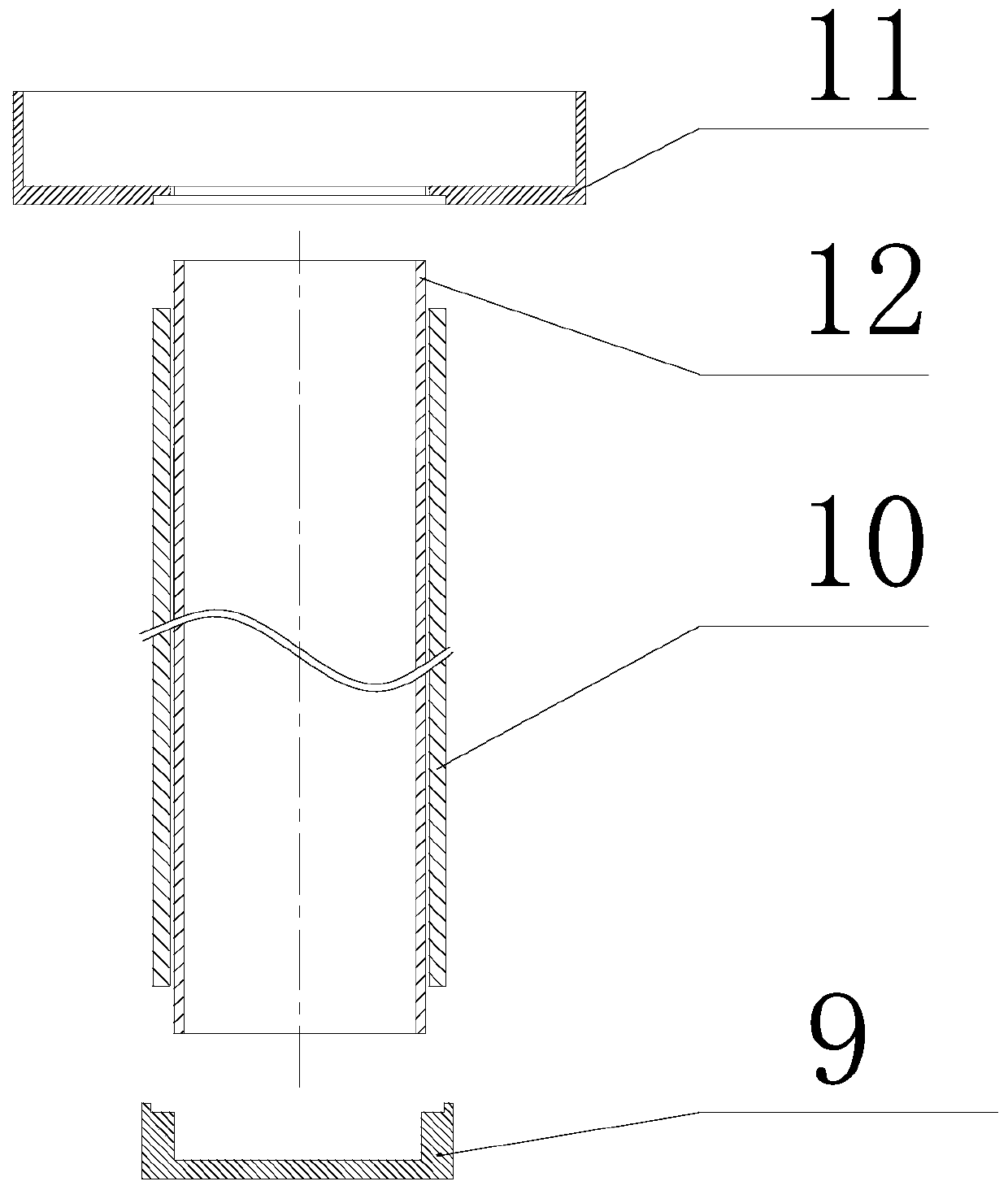

[0038] Step 2: Assemble the rotating target brazing device: install the back tube and the target on the positioning base, and then install the brazing disc on the upper end of the target.

[0039] Step 3: add brazing material: the brazing material is selected from metal indium, and the theoretical weight required for brazing is calculated according to the brazing g...

Embodiment 2

[0043] Prepare a rotating niobium target with a specification of OD145-ID125*L1940mm, where the specification of the target tube is OD 1 145-ID 1 134.5*L 1 1900mm, back pipe specification is OD 2 133-ID 2 125*L 2 1940mm.

[0044] Step 1: metallization of the inner surface of the target tube and the outer surface of the back tube: using an ultrasonic welding head to vibrate the brazing material into the surface of the target tube and the back tube to form a thin layer of brazing material. There is no special limitation on the metallization process, and the metallization process well known to those skilled in the art can be used.

[0045] Step 2: Assemble the rotating target brazing device: install the back tube and the target on the positioning base, and then install the brazing disc on the upper end of the target.

[0046] Step 3: Add brazing material: the brazing material is selected from metal indium, and the theoretical weight required for brazing is calculated accord...

Embodiment 3

[0050] Prepare a rotating silicon target with a specification of OD146-ID125*L1194mm, where the specification of the target tube is OD 1 146-ID 1 134.5*L 1 1150mm, back pipe specification is OD 2 133-ID 2 125*L 2 1194mm.

[0051] Step 1: metallization of the inner surface of the target tube and the outer surface of the back tube: using an ultrasonic welding head to vibrate the brazing material into the surface of the target tube and the back tube to form a thin layer of brazing material. There is no special limitation on the metallization process, and the metallization process well known to those skilled in the art can be used.

[0052] Step 2: Assemble the rotating target brazing device: install the back tube and the target on the positioning base, and then install the brazing disc on the upper end of the target.

[0053] Step 3: Add brazing material: the brazing material is selected from metal indium, and the theoretical weight required for brazing is calculated accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com