Grid-anode interdigital grid-controlled panel X-ray source and preparation method thereof

An X-ray and anode technology, applied in the direction of X-ray tubes, X-ray tube electrodes, X-ray tube components, etc., to achieve the possible effects of increasing the anode voltage, reducing the fringe electric field, and reducing the occurrence of discharge phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

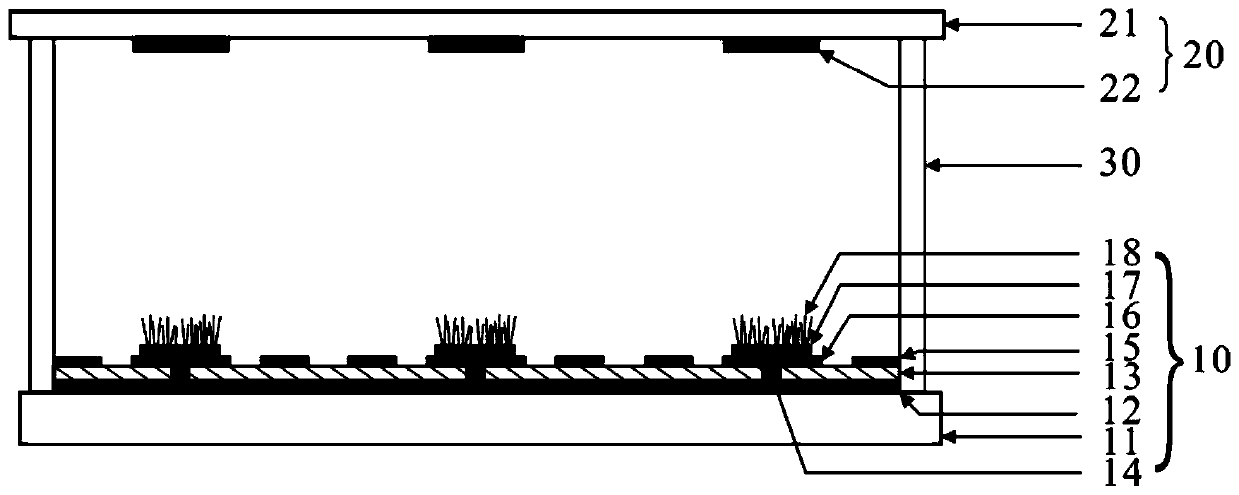

[0048] Such as figure 1 Shown is a schematic structural view of a grid-anode interdigitated grid-controlled flat panel X-ray source of the present invention.

[0049] The nano-cold cathode flat X-ray source of the present invention includes a cathode substrate 10 , an anode substrate 20 , and a high-voltage insulating spacer 30 . The cathode substrate 10 and the anode substrate 20 are arranged parallel to each other, and the high-voltage insulating spacer 30 is arranged between the cathode substrate 10 and the anode substrate 20 to separate and fix the cathode substrate 10 and the anode substrate 20 . There is a certain distance between the cathode substrate 10 and the anode substrate 20 .

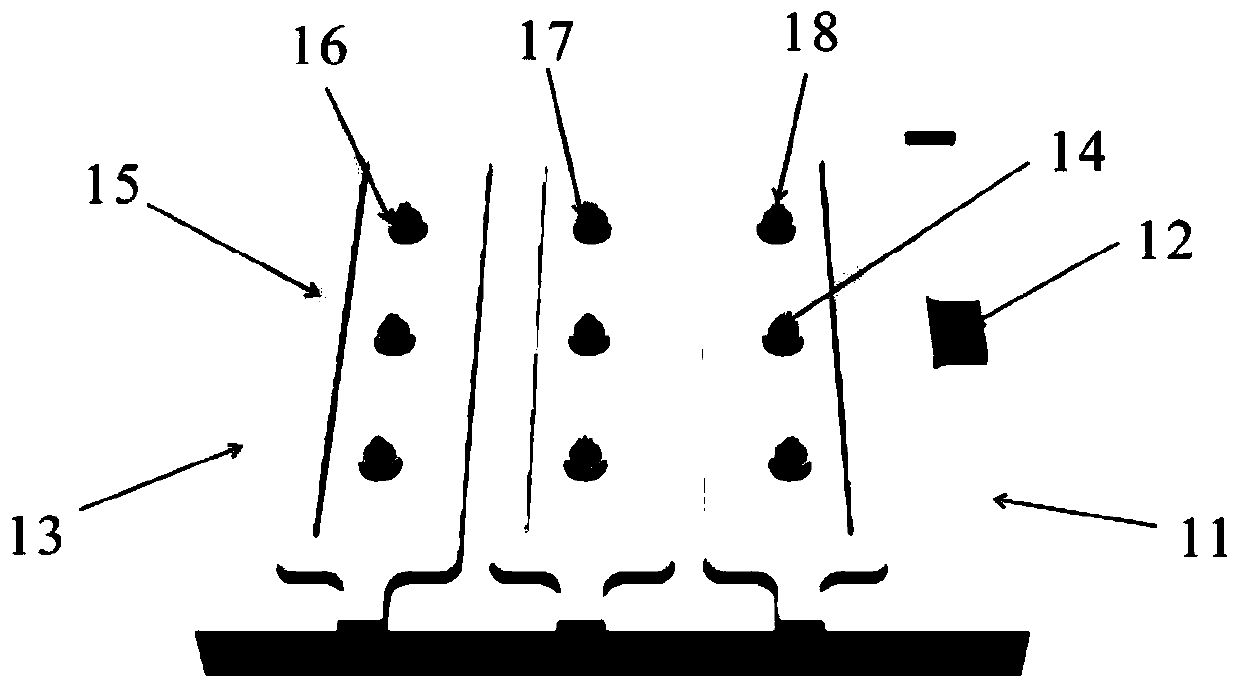

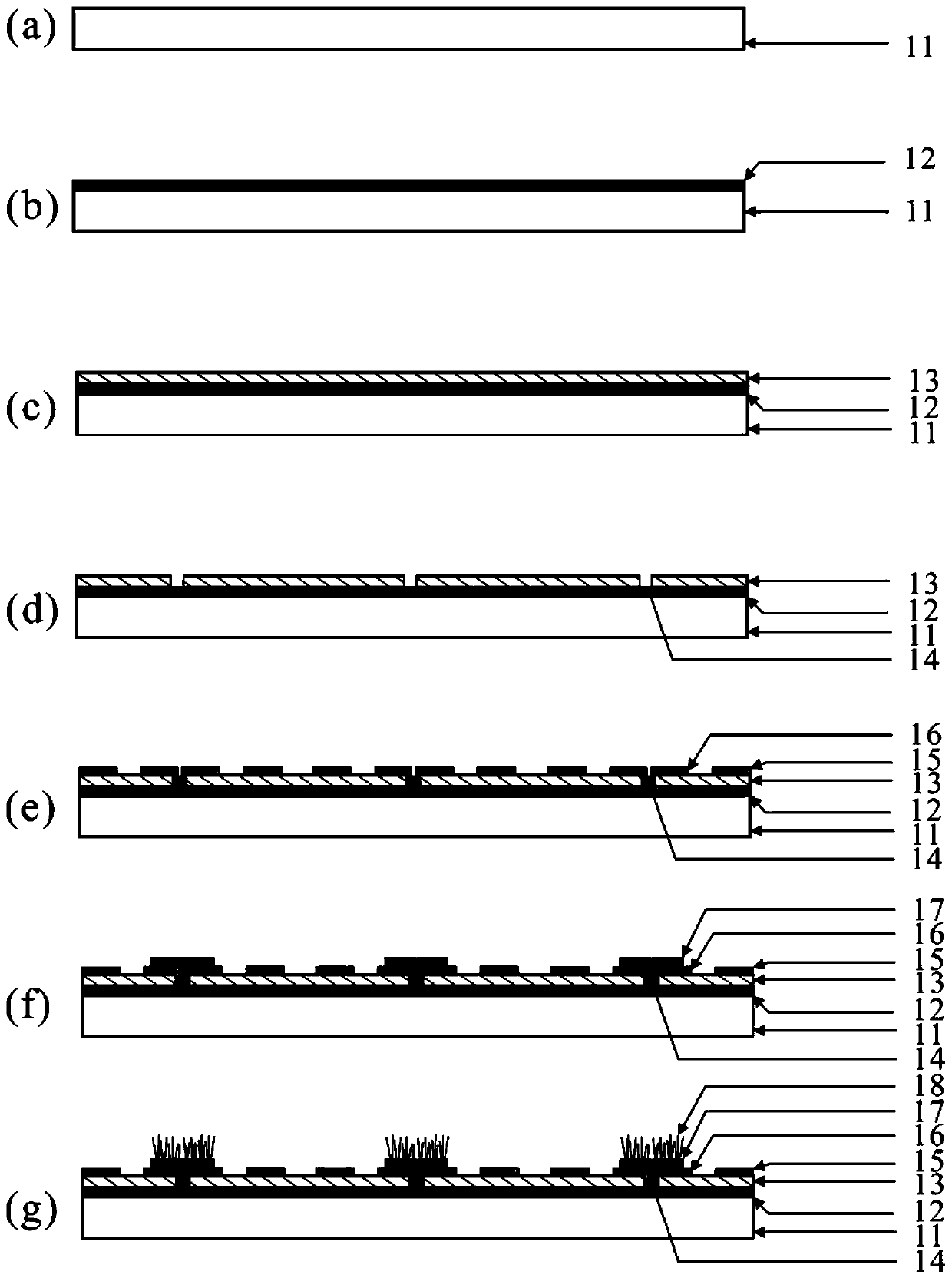

[0050] The cathode substrate 10 includes a cathode substrate 11, a bottom cathode electrode 12 disposed on the cathode substrate 11, an insulating layer 13, an etched through hole 14, a top gate electrode 15, a top cathode electrode 16, and a growth source film 17 and nanowire cold catho...

Embodiment 2

[0073] A fabrication method of a grid-anode interdigitated grid-controlled flat panel X-ray source is basically the same as that of Embodiment 1, the difference being that

[0074] The cathode substrate 10 is produced.

[0075] (1) The cathode substrate 11 is a large-area silicon wafer.

[0076] (2) The bottom cathode electrode 12 is Cr. The thickness of the bottom cathode electrode 12 is 0.1 μm,

[0077] (3) The insulating film as the insulating layer 13 is composed of a silicon nitride insulating film; the thickness of the insulating layer is 1 μm;

[0078] (4) The top grid electrode 15 and the top cathode electrode 16 are made of Cr, both of which have a thickness of 0.1 μm; their shape is “U”.

[0079](5) On the top cathode electrode 16, photolithography locates the nanowire cold cathode 18 growth region, and then deposits the growth source film 17; the growth source film 17 is copper, and its thickness is 0.3 μm; the diameter of the growth source film is 5 μm, and the...

Embodiment 3

[0087] A fabrication method of a grid-anode interdigitated grid-controlled flat panel X-ray source is basically the same as that of Embodiment 1, the difference being that

[0088] The cathode substrate 10 is produced.

[0089] (1) The cathode substrate 11 is large-area glass.

[0090] (2) The bottom cathode electrode 12 is Ti. The thickness of the bottom cathode electrode 12 is 2 μm,

[0091] (3) The insulating film as the insulating layer 13 is composed of an aluminum oxide insulating film; the thickness of the insulating layer is 5 μm;

[0092] (4) The top gate electrode 15 and the top cathode electrode 16 are made of Ti with a thickness of 2 μm; their shape is "V".

[0093] (5) The growth source film 17 is made of titanium with a thickness of 5 μm; the diameter of the growth source film is 500 μm, and the distance between adjacent growth source films 17 is 50 μm.

[0094] (6) The thermal oxidation growth process is carried out in a box furnace, the heating rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com