Preparation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device preparation, can solve the problems of uneven distribution of electric field in gate trenches, poor uniformity, affecting the electrical properties of semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

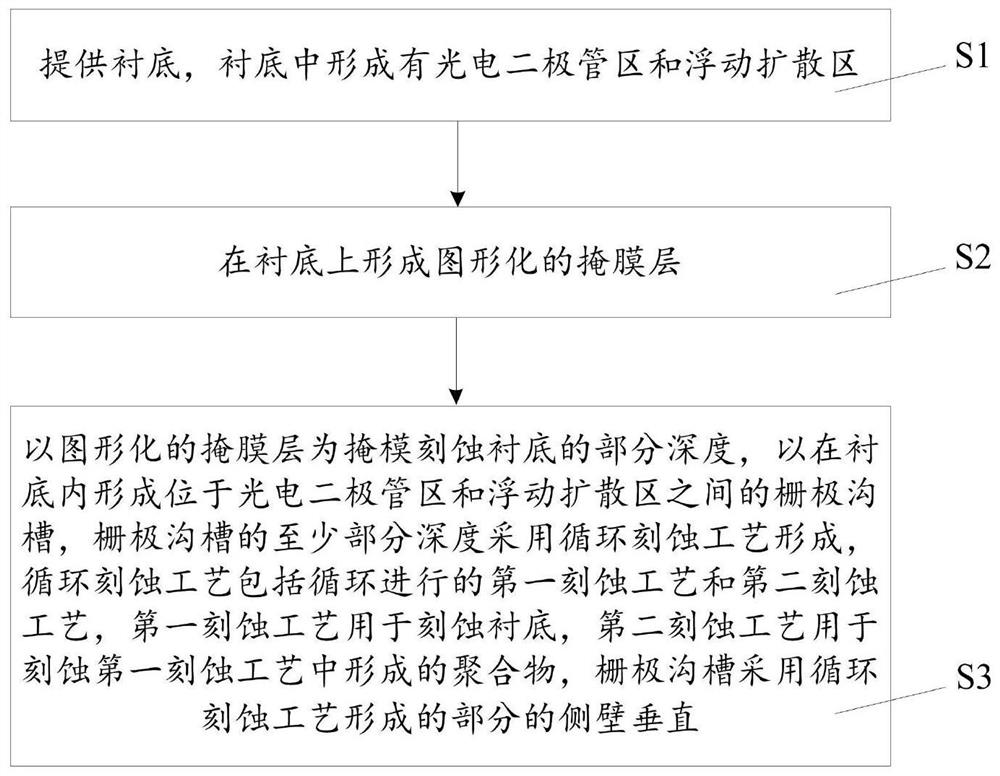

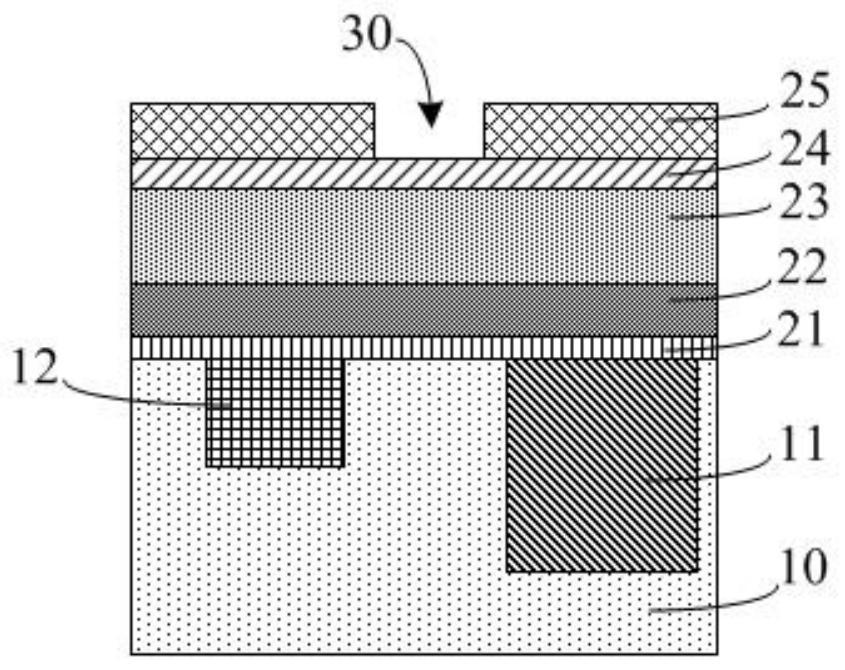

[0023] figure 1 It is a flow chart of the manufacturing method of the semiconductor device provided in this embodiment. This embodiment provides a method for manufacturing a semiconductor device, so as to reduce the generation of white pixels and improve the electrical performance of the device. Please refer to figure 1 , the preparation method of semiconductor device comprises:

[0024] Step S1: providing a substrate in which a photodiode region and a floating diffusion region are formed;

[0025] Step S2: forming a patterned mask layer on the substrate; and,

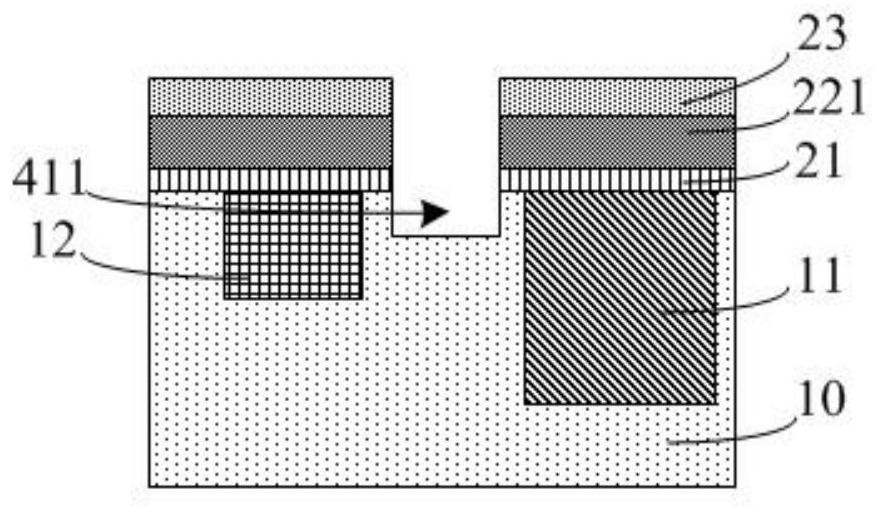

[0026] Step S3: using the patterned mask layer as a mask to etch part of the depth of the substrate to form a gate trench between the photodiode region and the floating diffusion region in the substrate, at least part of the gate trench The depth is formed by a cyclic etching process. The cyclic etching process includes a cyclic first etching process and a second etching process. The first etching process is used t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching power | aaaaa | aaaaa |

| Etching power | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com