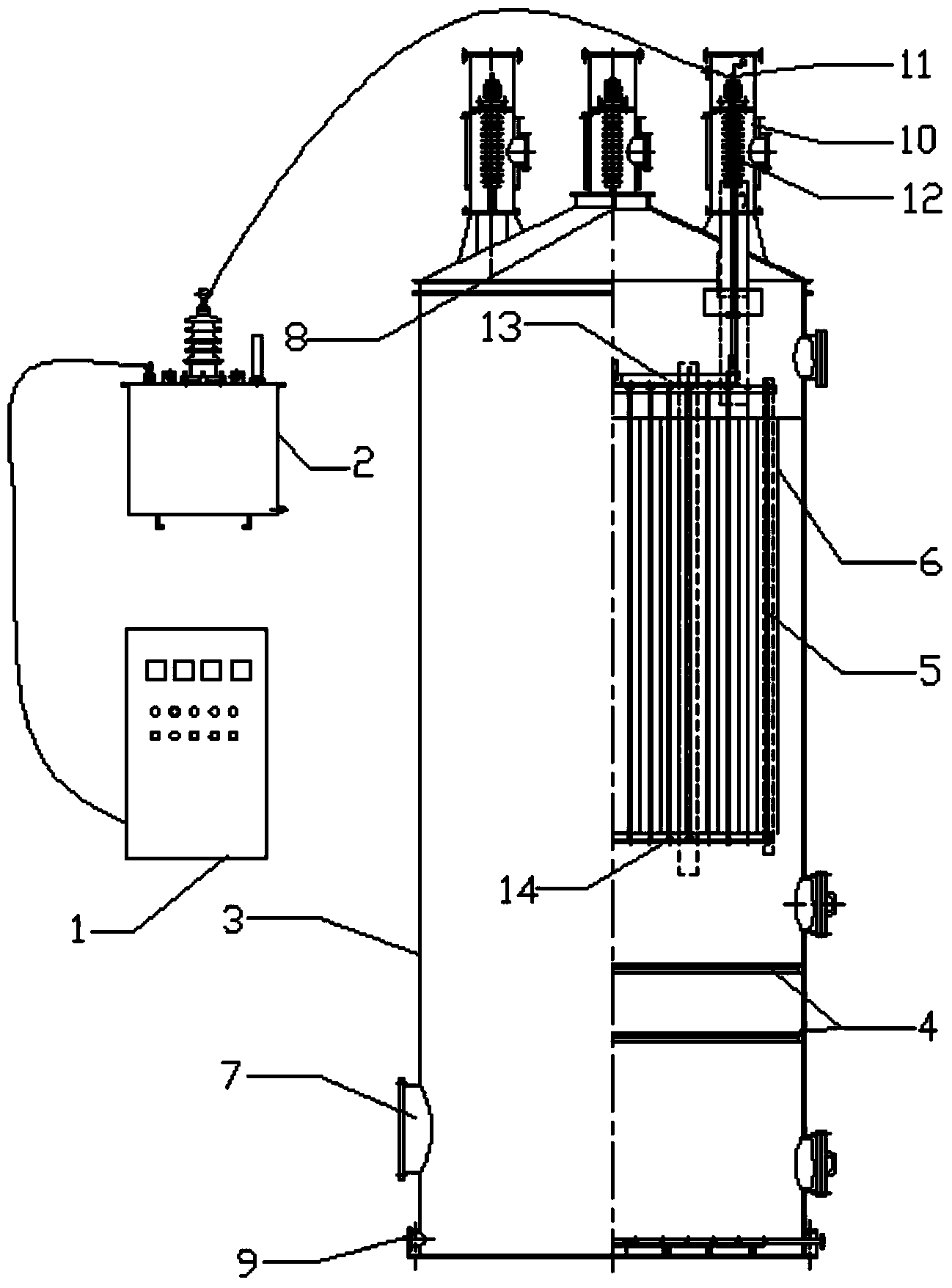

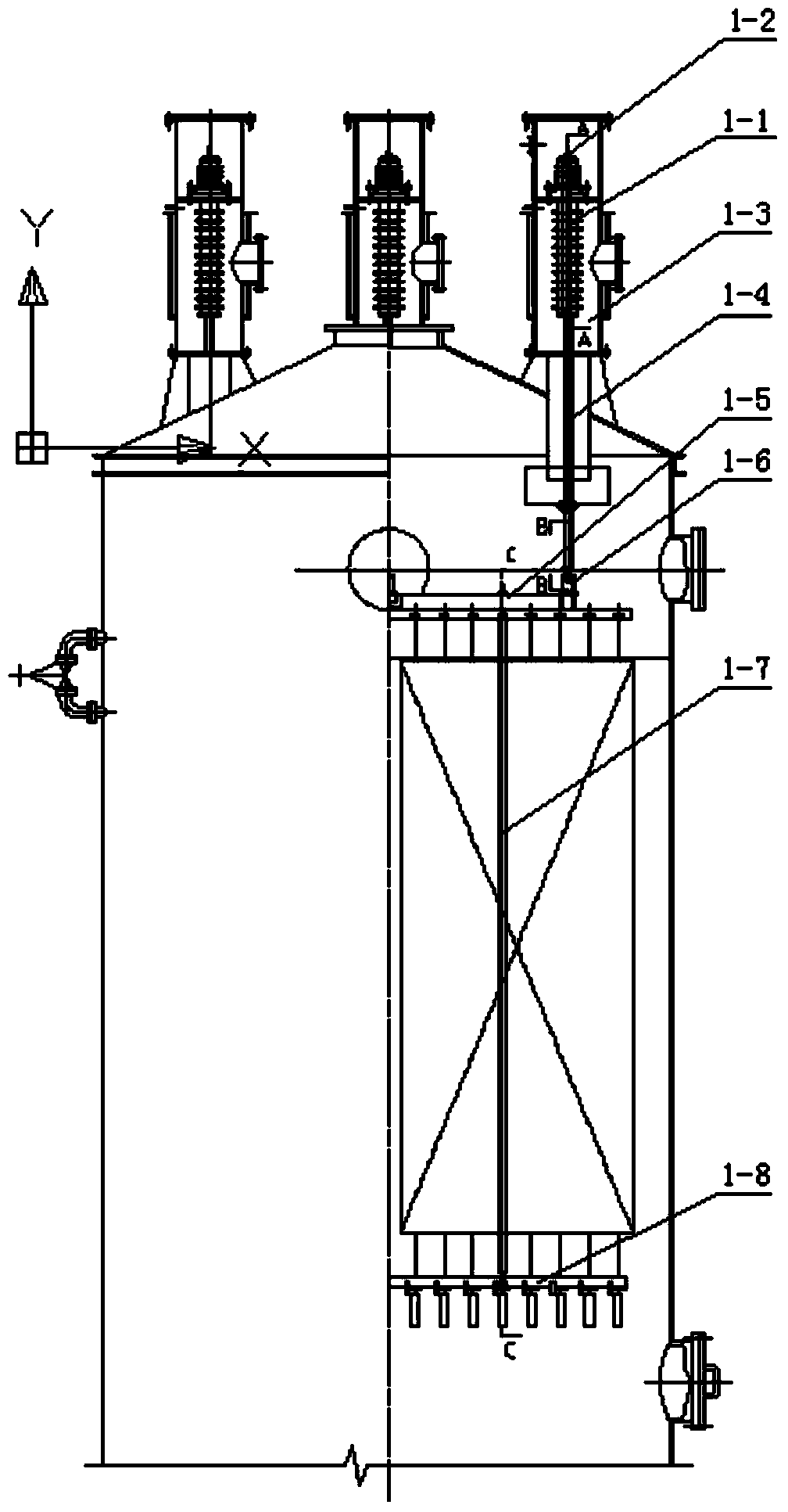

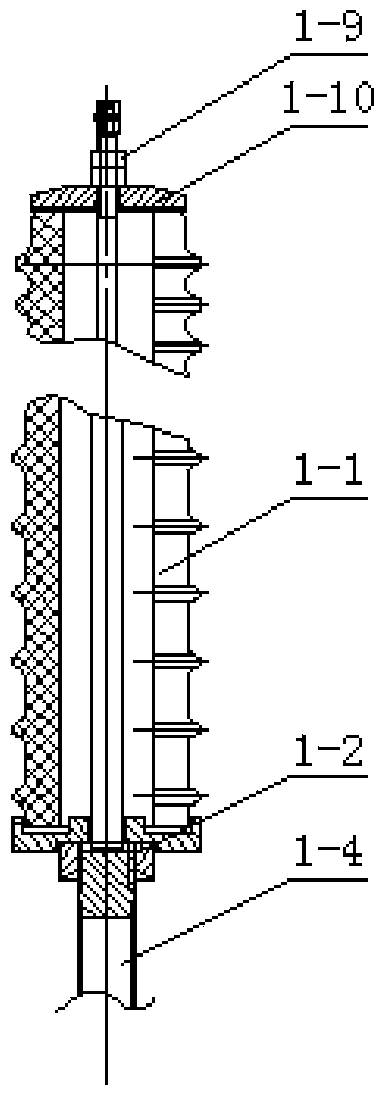

Honeycomb electrofilter with high flow rate

A technology of honeycomb and electric filter, applied in the field of high flow rate honeycomb electric filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0120] Table 1. Data comparison between single-phase power supply and three-phase power supply under the same conditions

[0121]

Flashover point voltage KV

Secondary voltage KV

Secondary current mA

Corona power KW

Single-phase constant current source

52

50

260

13

Three-phase constant current source

67

62

650

40.3

Three-phase single-phase added value

12

390

27.3

Three-phase single-phase added value

24%

150%

210%

[0122] Table 2. Comparison table of secondary current of two corona electrodes under the same conditions and voltage

[0123]

[0124] Table 1 shows that the power of the three-phase power supply is 2.1 times higher than that of the single-phase power supply under the same working conditions; the voltage at the flashover point represents the working limit voltage, that is, it cannot work when it reaches the voltage at the flashover point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com