Measuring method of grain layer thickness and judging method of grain layer abnormality

A thickness measurement and grain layer technology, applied in measurement devices, material analysis using measurement secondary emissions, and wave/particle radiation, etc. Reduce the discharge phenomenon, overcome the effect of easy charging and clear layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

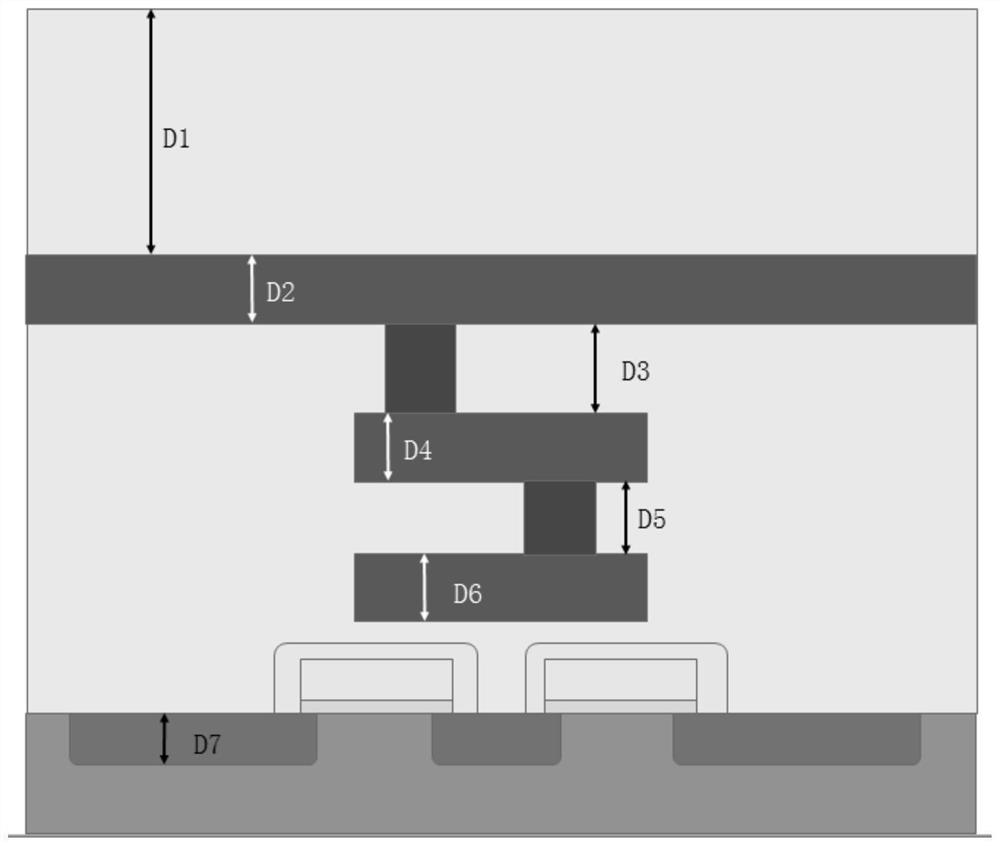

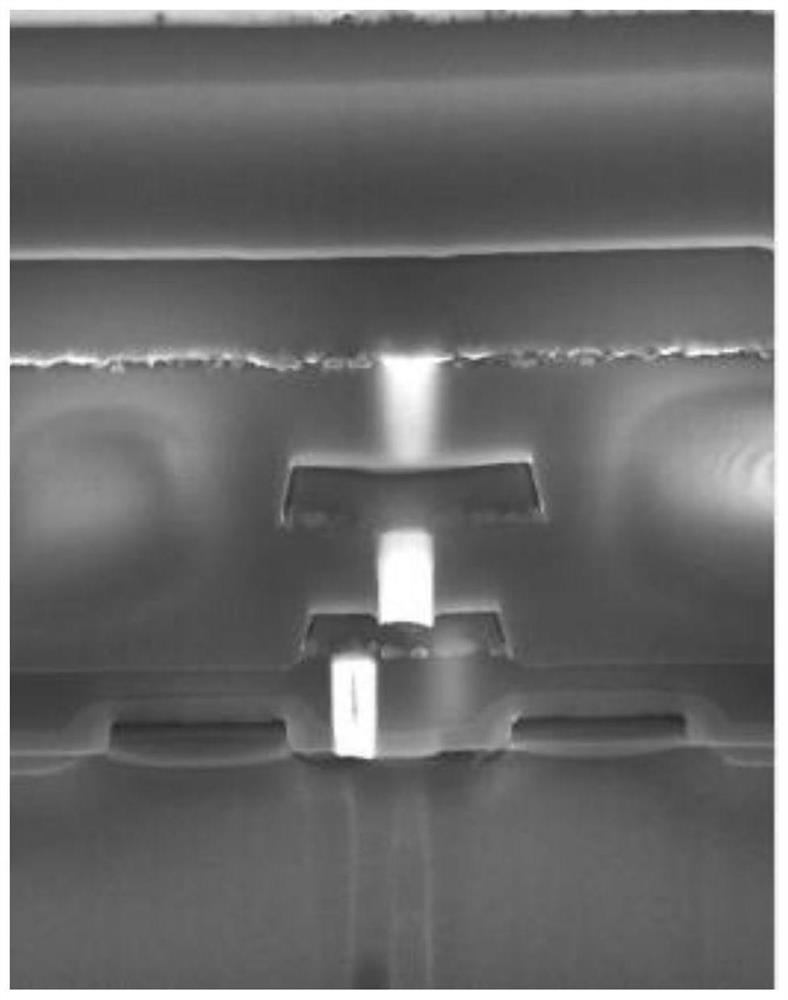

[0048] Such as Figure 2-6 As shown, the present invention provides a method for measuring the thickness of the grain layer. This embodiment is a method for measuring the thickness of each layer in a single grain layer structure, and the method at least includes the following steps:

[0049] Step S10: Process the grains to be tested to the target area using FIB;

[0050] Step S20: instill in the target area by CH 3 COOH, HNO 3 , HF or H 2 O, HNO 3 The mixed acid solution formed by mixing HF according to the preset ratio is cleaned after standing for a preset time, and the residual liquid of the crystal grains to be tested is removed to obtain the test sample;

[0051] Step S30: Using the SEM to observe and measure the test sample at a preset voltage.

[0052] In step S10, the sample to be tested is processed to a target area by using FIB, and the target area is the exposed area of the grain to be tested after being treated by FIB, such as the area of the longitudinal...

Embodiment 2

[0057] Such as Figure 7 As shown, the present invention also provides a method for measuring the thickness of the grain layer of a chip, including the method for measuring the thickness of the grain layer as provided in Example 1, and also includes a step before step S10: using a laser and / or a chemical unsealing method to remove the chip The packaging structure exposes the die inside the chip.

[0058] Specifically, the embodiment of the present invention can use the chemical unsealing method or the laser laser method to remove the packaging structure outside the chip. The first step is to remove the plastic package from the chip to be tested, so as to avoid damage to the grain layer structure of the chip by laser method alone. First use the laser method to remove most of the plastic packaging film of the chip to be tested, and then unpack it with chemicals to expose the internal crystal grains of the chip package. For chips soldered with gold wires, the chemical agent in ...

Embodiment 3

[0060] The invention also provides a method for judging the abnormality of the grain layer. The abnormality of the grain layer mainly means that the thickness of each structural layer in the grain layer deviates from the design standard value, which makes the grain have the risk of failure. The thickness of the grain layer is measured by the method provided in Embodiment 1 and compared with the standard value to determine whether there is an abnormality in the thickness of the grain and whether there is an abnormal layer. If it is within the standard value range, there is no abnormality in the grain layer; if the measured value of a certain layer in the grain layer, such as the measured value of D3 layer, exceeds the standard value range, it can be confirmed that there is an abnormality in the grain layer, and the abnormal position is at D3 layer. Wherein, the standard value may be a design standard value during design, or a standard reference value for a specific type of waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com