Dry-type high-frequency transformer

A dry-type transformer and insulating layer technology, applied in the direction of fixed transformer or mutual inductance, transformer/inductor parts, transformer/inductor coil/winding/connection, etc. problems, to avoid gaps and cracks, small partial discharge, and ensure the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

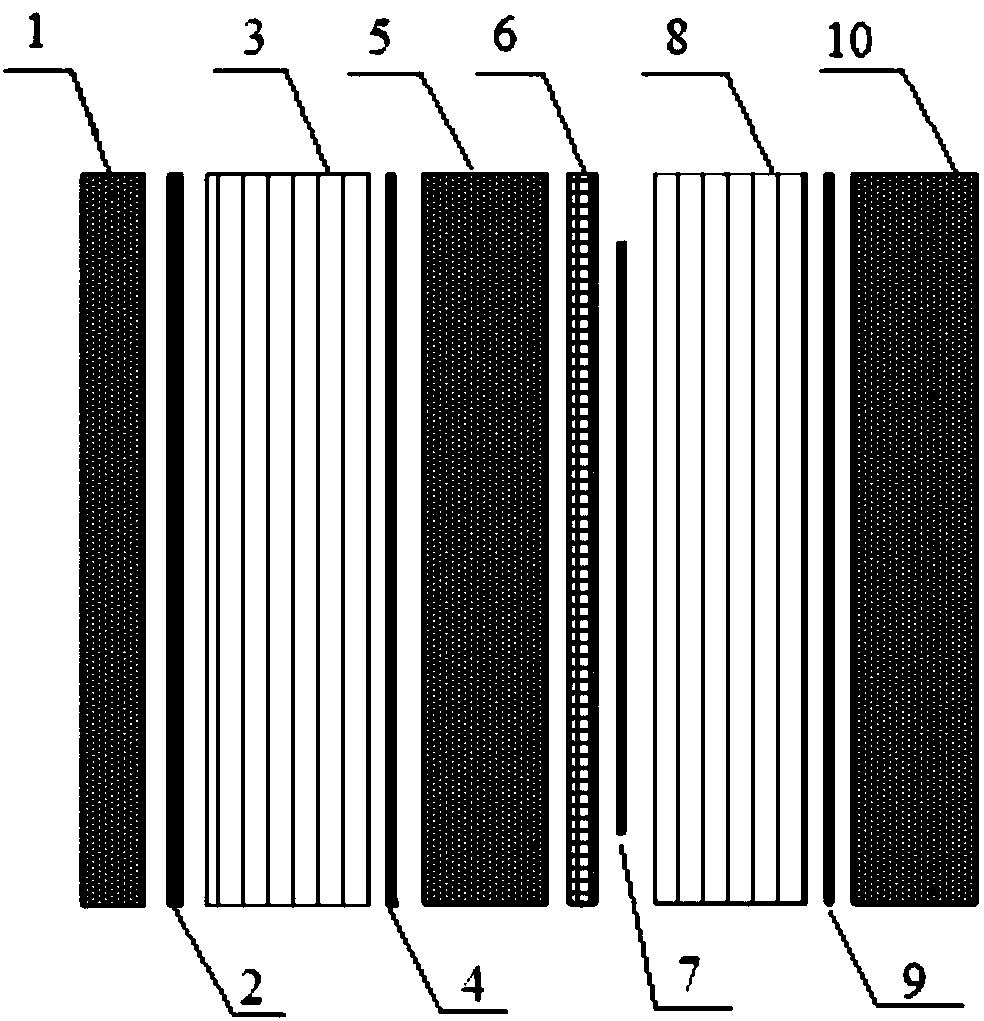

[0036] The winding with an insulation structure provided in this embodiment includes a first insulation layer, a transition layer one, a coil, a transition layer two, and a second insulation layer in sequence. The coil is made of ionic conductor material as a wire. The turns of the coil are separated by insulating materials. DMD insulating composite material can be selected. The first insulating layer and the second insulating layer are made of cast epoxy resin. The transition layer is one And the second transition layer is made of silicone rubber sheet.

[0037] By providing a transition layer between the coil and the insulating layer, it can play a buffering role, reduce the phenomenon of air gaps and cracks at the interface between the insulating layer and the coil, avoid creeping discharge, thereby improving the insulation performance and reducing the level of partial discharge. The insulating elastic material is a preferred transition layer material.

Embodiment 2

[0039] The winding with insulation structure provided in this embodiment is structurally the same as the winding with insulation structure provided in the embodiment. The difference is that the second transition layer of this embodiment is made of electrostatic shielding material semiconductor crepe paper. In this way, the second transition layer It can not only play a certain buffering effect, but also shield the electric field outside the coil, achieve the effect of uniform electric field, and further reduce the level of partial discharge, thereby preventing the occurrence of short-circuit breakdown.

Embodiment 3

[0041] The winding with an insulating structure provided in this embodiment includes a first insulating layer, a transition layer one, a coil, a transition layer two, and a second insulating layer in sequence. Among them, the first transition layer and the second transition layer are made of electrostatic shielding materials.

[0042] By selecting the electrostatic shielding material as the material of the transition layer 1 and the transition layer 2, the electric field inside and outside the coil can be well shielded, making this winding with an insulating structure more suitable for high-voltage windings and has better insulation performance. The partial discharge level is minimized to ensure that the winding with an insulating structure is safe and reliable during long-term operation.

[0043] In this embodiment, a semiconductor self-adhesive tape is used as an electrostatic shielding material, an elastic insulating material silicon rubber plate is used as a transition layer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com