Preparation method of copper-steel composite material with self-generated copper-rich layer on steel surface

A composite material and copper-rich technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of matrix and cladding layer inclusions, bubbles, intervals, etc., to achieve high strength, beautiful appearance, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0025] A method for preparing a self-generated copper cladding layer on the surface of steel caused by selective oxidation, the method steps are as follows:

[0026] 1. Preparation of copper-containing steel: a vacuum induction melting furnace (or a melting furnace filled with protective gas) is used to prepare copper-containing steel with a copper content of 6.8% by mass.

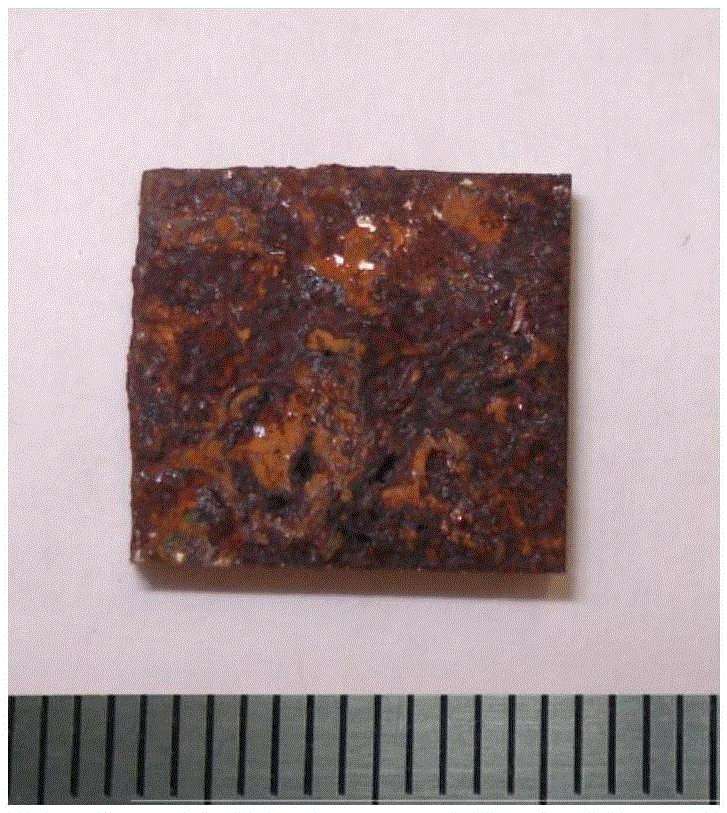

[0027] 2. Surface corrosion of copper-containing steel: take samples of the prepared copper-containing steel and conduct laboratory accelerated corrosion experiments. The corrosion reagent is 0.5% NaCl solution. Cycle, the total time of corrosion is 10 days, that is, 240 hours. After corrosion samples such as figure 1 shown.

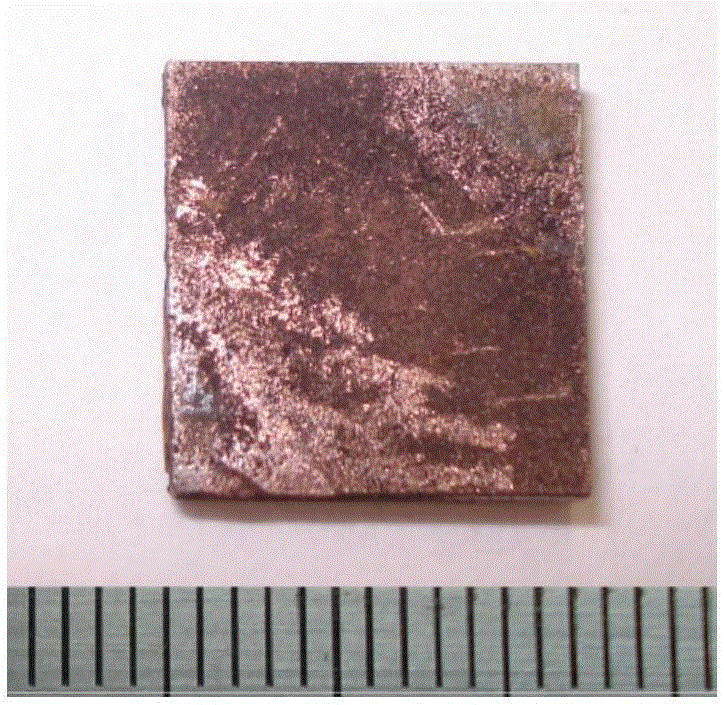

[0028] 3. Prepare rust remover to remove iron oxide scale: use 5% sodium dihydrogen phosphate, 5% citric acid, and 90% deionized water as the rust remover, and soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com