A kind of titanium-iron-stainless steel three-layer composite plate butt welding process method

A process method, stainless steel technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of high welding joint strength, high welding efficiency, low production cost, etc. good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

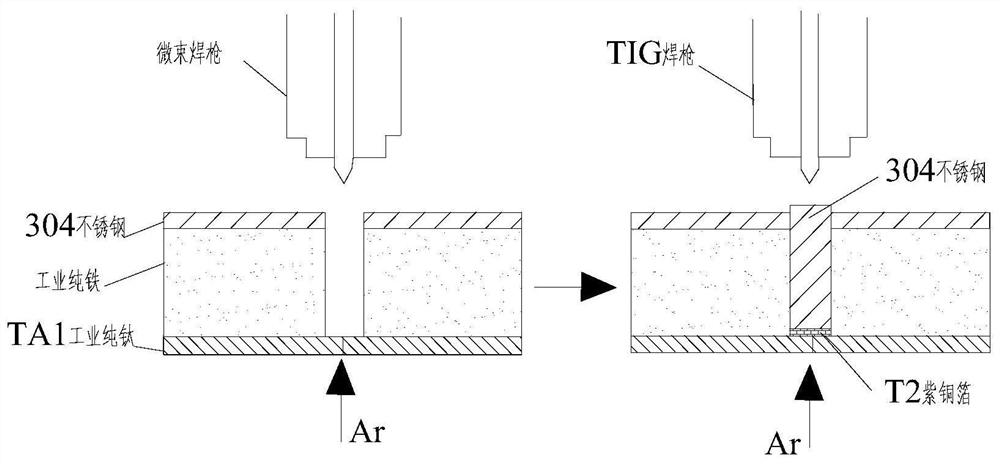

[0039] In this embodiment, welding is carried out by taking a 1.5mm titanium-iron-stainless steel three-layer composite plate as an example, wherein the base layer is industrial pure iron with a thickness of 1mm, the thickness of the titanium cladding is 0.2mm, and the thickness of the stainless steel cladding 0.3mm. For the butt welding process of the titanium-iron-stainless steel three-layer composite plate, its schematic diagram is shown in figure 1 , using the following welding scheme:

[0040] Step 1: Processing welding groove

[0041] Before welding, the metal on both sides of the base material of the titanium-iron-stainless steel three-layer composite plate is ground to remove the oxide on the surface of the cladding.

[0042] The titanium-iron-stainless steel three-layer composite plate is clamped by the fixture, and the groove is processed on the milling machine. One side of the titanium cladding is facing down, and the iron base layer and stainless steel cladding ...

Embodiment 2

[0055] In this embodiment, welding is carried out by taking a 2mm titanium-iron-stainless steel three-layer composite plate as an example, wherein the base layer is industrial pure iron with a thickness of 1.4mm, the thickness of the titanium cladding is 0.3mm, and the thickness of the stainless steel cladding 0.3mm. For the butt welding process of the titanium-iron-stainless steel three-layer composite plate, the following welding scheme is adopted:

[0056] Step 1: Processing welding groove

[0057] The base material of the titanium-iron-stainless steel three-layer composite plate is processed, and the edges to be welded in the base material of the titanium-iron-stainless steel three-layer composite plate are mechanically processed by a milling machine, and the stainless steel cladding and iron base layer are processed, and the titanium is retained. The cladding, as the welding groove, the width of the remaining titanium cladding is 1.0mm, and the base material of the clad ...

Embodiment 3

[0067] In this embodiment, welding is carried out by taking a 2mm titanium-iron-stainless steel three-layer composite plate as an example, wherein the base layer is industrial pure iron with a thickness of 1.4mm, the thickness of the titanium cladding is 0.3mm, and the thickness of the stainless steel cladding 0.3mm. For the butt welding process of the titanium-iron-stainless steel three-layer composite plate, the following welding scheme is adopted:

[0068] Step 1: Processing welding groove

[0069] The base material of the titanium-iron-stainless steel three-layer composite plate is processed, and the edges to be welded in the base material of the titanium-iron-stainless steel three-layer composite plate are mechanically processed by a milling machine, and the stainless steel cladding and iron base layer are processed, and the titanium is retained. The cladding, as the welding groove, the width of the remaining titanium cladding is 1.0mm, and the base material of the clad ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com