A polyphenylene sulfide powder coating with both anti-corrosion and fire-proof functions

A polyphenylene sulfide, powder coating technology, applied in powder coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problem of poor compatibility between anti-rust and anti-corrosion primers and fire-resistant coatings, reducing fire-resistant effects, and surface fire-resistant coatings falling off and other problems, to achieve excellent anti-corrosion performance, promote compatibility, and have the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A polyphenylene sulfide powder coating with both anti-corrosion and fire-proof functions, the coating includes the following components:

[0026] Polyphenylene sulfide: 40

[0027] Titanium dioxide: 5

[0030] Silane coupling agent: 1

[0031] Expandable graphite powder: 3

[0032] Microcapsule modified ammonium polyphosphate: 10

[0033] Microencapsulated Melamine: 10

[0034] Microencapsulated pentaerythritol: 10

[0035] Dispersant, using Shanghai Jinshan Chemical Co., Ltd. JS-V966: 0.5

[0036] Leveling agent, using Shanghai Jinshan Chemical Co., Ltd. JS-3038: 0.5

[0037] Fatty alcohol polyoxyethylene methyl-terminated polyether: 15,

[0038] The above raw materials are in kg.

[0039] The preparation method of fatty alcohol polyoxyethylene methyl-terminated polyether is as follows: add AEO-9 (fatty alcohol polyoxyethylene ether), NaOH and sodium methylate in a three-necked flask with a molar ratio of 1:0...

Embodiment 2

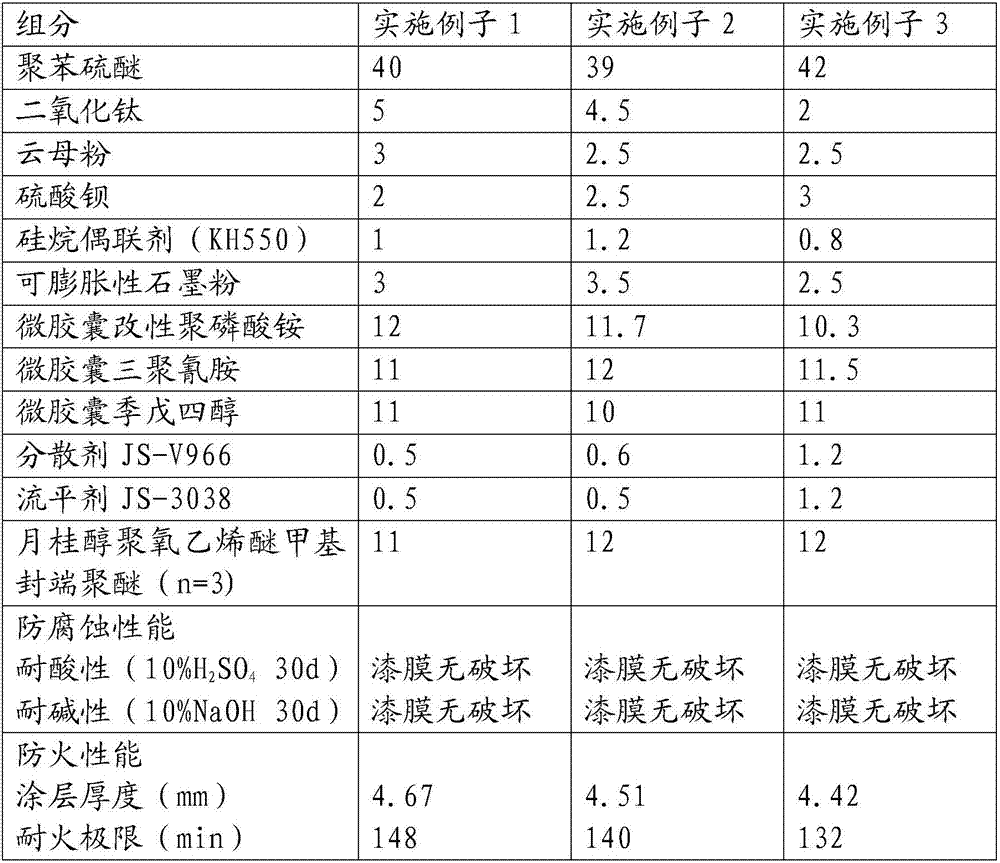

[0050] Both Example 2 and Example 3 adopt the preparation method and process steps of Example 1, and only change the coating formula, and then see Table 1 for the specific indicators after the performance test.

[0051] Table 1 embodiment 1-3 each component consumption and test result

[0052]

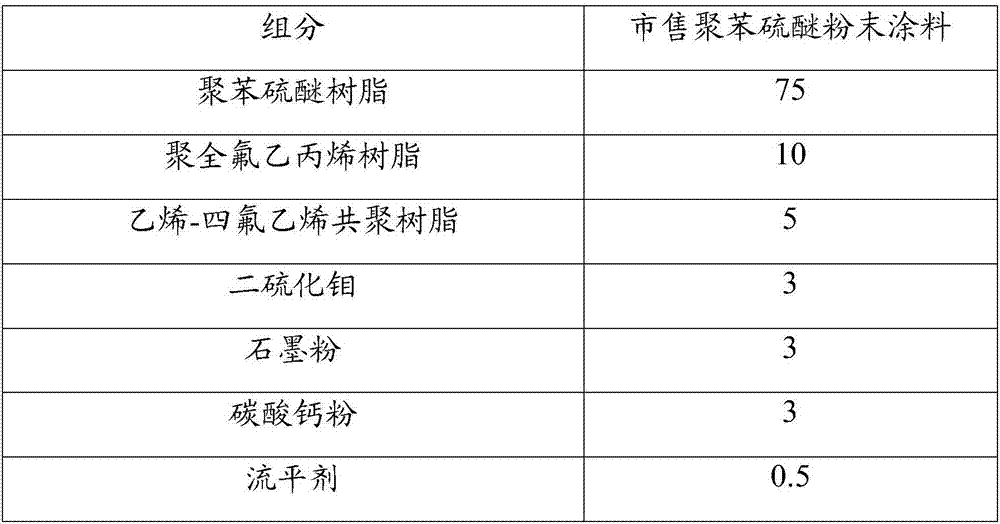

[0053] In order to further clarify that the polyphenylene sulfide powder coating developed by the present invention has excellent anti-corrosion and fireproof properties, a group of commercially available polyphenylene sulfide powder coatings and a group of commercially available ammonium polyphosphate fireproof coatings are selected for comparative testing, formula and performance testing The results are shown in Table 2 and Table 3.

[0054] Table 2 Commercially available polyphenylene sulfide powder coating formula table

[0055]

[0056]

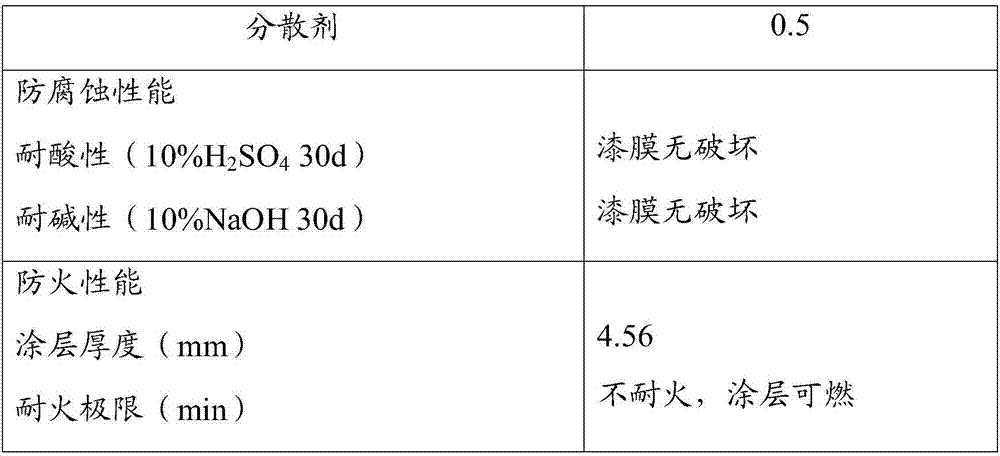

[0057] Table 3 Commercially available ammonium polyphosphate fireproof coating formula table

[0058]

[0059] From Table 1, Table...

Embodiment 4

[0061] To prepare the polyphenylene sulfide powder coating, the proportioning is carried out according to the following mass ratios, and the following raw materials are all commercially available, and the unit is kg. The specific list is as follows:

[0062]

[0063] Taking Example 4 as an example, simply mixing anti-corrosion components (such as polyphenylene sulfide) and fire-proof components (such as ammonium polyphosphate, melamine, pentaerythritol), even if the dosage is increased, the desired anti-corrosion and fire-proof effects cannot be achieved. And coating physical property is very poor, and reason is: the used ammonium polyphosphate of the technical scheme of the present invention, melamine, pentaerythritol all carry out microencapsulation treatment, have added fatty alcohol polyoxyethylene methyl capped polyether simultaneously, the purpose of doing like this is Let the fireproof components be well compatible with polyphenylene sulfide resin during the electros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com