Installation body for automobile temperature switch

A technology of temperature switch and installation body, applied in the direction of thermal switch parts, etc., can solve the problems of heavy weight and high price, and achieve the effect of reducing weight, saving resources and reducing the weight of automobiles

Inactive Publication Date: 2013-09-25

曲阜天博汽车零部件制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the disadvantages of high price and heavy specific gravity of the installation body of the existing automobile temperature switch, and provide a low price, light specific gravity and good performance automobile temperature switch installation body

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

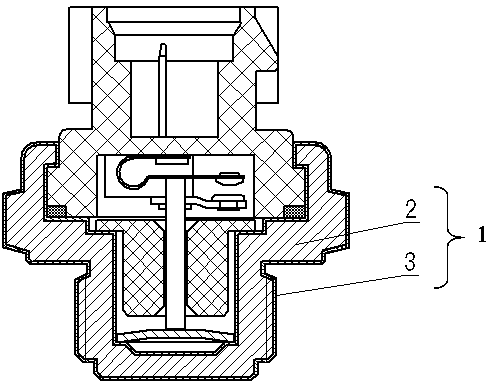

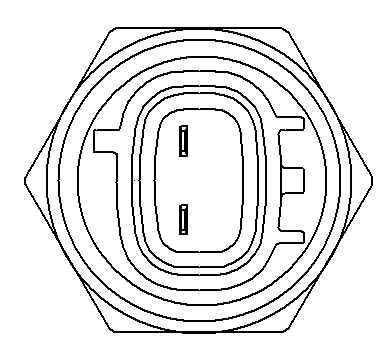

[0013] Such as figure 1 A car temperature switch is shown, wherein the installation body 1 on the temperature switch is composed of an aluminum alloy substrate 2 and a copper coating 3, that is, the installation body 1 is made of an aluminum alloy base material, and the surface of the aluminum alloy base material is coated with a copper coating layer 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an automobile temperature switch, and particularly provides an installation body for the automobile temperature switch. The installation body comprises an aluminum alloy substrate and a copper plating. According to the installation body, the aluminum alloy substrate is adopted, and the copper plating is plated on the surface of the aluminum alloy substrate. The installation body for the automobile temperature switch can lower cost and save resources effectively, and can reduce the weight of the automobile temperature switch, thereby reducing the weight of an automobile.

Description

technical field [0001] The invention relates to an automobile temperature switch, more specifically to an installation body used on the automobile temperature switch. Background technique [0002] Temperature switches are widely used in the automotive field. At present, the installation body used on the temperature switch is generally made of copper alloy material. Due to the high price and heavy specific gravity of this material, the installation body on the automobile temperature switch urgently needs a material with low price and light specific gravity. . Contents of the invention [0003] The purpose of the present invention is to overcome the disadvantages of high price and heavy specific gravity of the existing automobile temperature switch installation body, and provide a low price, light specific gravity and good performance automobile temperature switch installation body. [0004] The technical solution adopted by the present invention to solve the technical prob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H37/04

Inventor 孔凡留史桂洋谭立国

Owner 曲阜天博汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com